Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

Similar documents

The annual salary fund, the cost of electricity and the amount of depreciation. Costs for major repairs. Feasibility study of the power supply system and electric drive. The cost of installation and summary technical and economic indicators.

course work, added 27/07/2010

Technology and the necessary mechanisms and devices for the installation of electrical equipment boiler. The main circuit of its power supply, the choice of the light source and its location. Documentation for the commissioning of electrical equipment.

thesis, added on 06/02/2015

Choice of power supply category. The scheme of connections of substations. Calculation of electrical loads. Short-circuit current. Fuses on the outgoing lines. The technology of EMP production. Machines, mechanisms and tools used in production.

term paper, added on 05/08/2014

Characteristics of the mounted equipment: purpose, design and principle of operation. Selection of delivery methods to the installation site. Transport and load-lifting mechanisms. Development of the layout of the installation site. Networking of electrical installation works.

course work, added 01.08.2012

A study of methods for performing the installation of open and hidden internal postings, electric motors, start-protection equipment and installation fixtures. Consideration of measures on labor protection and safety precautions in the performance of electrical installation works.

report on practice, added on 10/13/2014

Brief description of the designed repair and mechanical shop. Selection of light sources, luminaires and the location of the lighting flaps. Recommendations on the technology of electrical installation works. Feasibility study of the project.

term paper, added on 05/25/2015

Brief description of the mechanical shop, list of electrical equipment. Determination of electrical loads and compensating device. Selection of substation transformers. Calculation of short circuit currents. Drawing up of statements of electrical installation works.

term paper, added on 01/17/2014

Preparation of the process for electrical work. Analysis of expansion joints and additional bends of the line cable, necessary for removing the mechanical stress from the coupler coupling. The possibility of warming and protecting the workplace from atmospheric precipitation and dust.

course work, added on 03/29/2017

Methods for calculating electrical loads. Calculation and selection of the supply and distribution network 0,4 kV. Calculation and selection of the location, power and number of transformers of the transformer substation. Organization and preparation of electrical installation works.

thesis, added on 05/22/2016

The technique of cutting the cable and drawing up a technical map of electrical installation works. Determination of the resistance of the stages of the resistors by the method of segments. Safety instructions, safe working methods at chemical industry enterprises.

laboratory work, added on 12/01/2010

Calculation of electrical loads by the method of ordered diagrams. Compensation for reactive power. Calculation of power losses in the transformer and relay protection. Selection of supply voltage networks. Cost of equipment operation, calculation of electrical work.

thesis, added on 01/20/2016

General information on the polarization and electrical breakdown of dielectrics, on the magnetization of ferro- and ferrimagnetics. Physical properties of electrical insulating materials, active dielectrics and magnetic substances. Directions of technical application of materials.

study guide, added on 9/9/2015

Description of the enterprise "Bratsk Electric Grid Company". The structure of the power supply microdistrict. The order of labor safety and safety in the production of electrical installation works. Calculation of loads and electrical equipment of the substation of microdistrict No. 3.

thesis, added 10/09/2016

Transformer substations and their purpose for conversion and distribution electric power. Separation of the design. Type of substation on an A-shaped wooden support. Organization of labor and mechanization of electrical work.

term paper, added on 01/03/2017

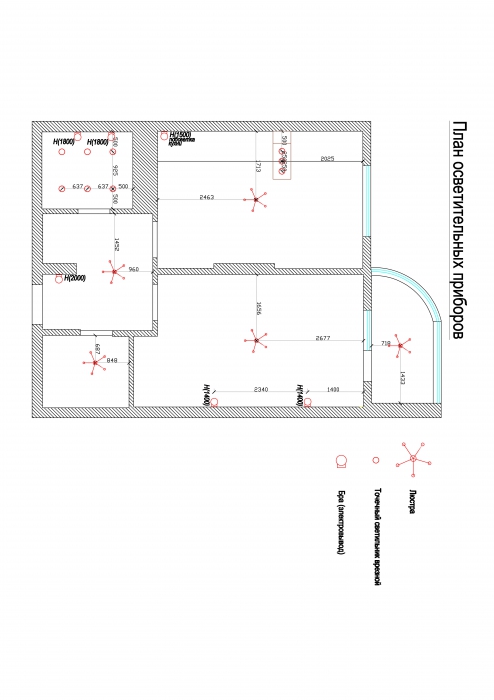

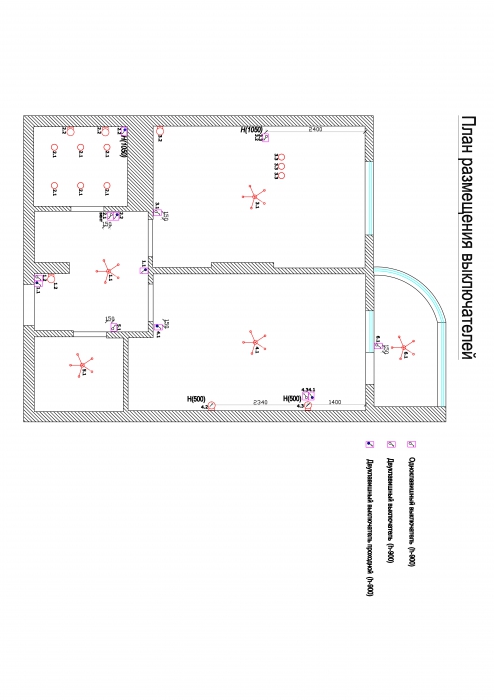

Development of the layout of electrical wiring and electrical lighting on the facility's layout. Determination of the conductors of wires and cables. Recommendations for the implementation of electrical work at the facility, a list of tools, devices and mechanisms.

Page 6 of 16

Project of work production is the main document for the preparation of production. It develops all the main technical, technological and organizational issues of preparation and execution of electrical installation works. In the "Instruction for the development of projects for the organization of construction and projects for the production of works" (SN 47-74) of the USSR State Construction Committee, the main directions of the development of the PPR are defined. Materials PPD help installers in familiarizing themselves with project documentation, timely ordering of electrical installation materials and monitoring the supply of equipment, organization and performance of work. For large and complex objects, the PPR is developed by specialized organizations, for all other objects - assembly trusts and managements. Projects for the production of works are divided into standard and individual, and in terms of composition, they are developed and reduced. Typical IDPs are for housing, socio-cultural Appointments and other facilities, the construction of which is based on the type projects or documentation that are being re-applied. Reduced RWP is for technically simple objects with a small amount of work. Full PPD is developed for large construction complexes, built on individual projects with the use of new technical solutions. The composition of any PPR is required to be minimal in scope and specific in content. The materials in the project documentation should not be repeated in it.

The source materials for the preparation of the PDP are working drawings, estimated documentation and the construction project; data on the order and delivery dates of the main equipment and materials by the customer and the general contractor; information on the availability of machines, mechanisms and the possibilities of their use; current regulatory documents - EMP, SNiP, building codes, installation instructions and guidance materials on safety. In accordance with the current instruction of VNIIPEM, the PPR materials are divided into several groups: a handbook, organization and technology of work at the facility, logistics, assignment of the IES, and calculation of labor costs for work in the assembly area.

The first part consists of an explanatory note, which reflects general information on the object and its characteristics, a brief description and a schematic diagram of electricity supply taking into account the requirements of the technological process of the enterprise under construction, a table of technical and economic and electrical indicators - physical volumes; estimated cost, output, labor intensity. On a reduced scale, a general plan is placed with the indication of the title list objects and the allocation of electrical facilities, as well as the power drainage routes. List the changes made in the working drawings when developing the PPR, agreed with the customer, and if necessary - with the project organization. The statement of physical volumes gives a general idea of the scope of work, the quantity power transformers and their installed capacity, the number of electric motors with a voltage of up to 1000 V and higher, with separation on the motors of variable and direct current, complete devices with division into cameras, shits, cabinets and consoles. Specify the information about hoisting-and-transport devices with breakdown by quantity and carrying capacity. List materials and cable products for installation of networks. For cables and wires indicate types, nominal voltage and purpose. Separately list trunk, distribution and other types of bus bars, tires and non-ferrous metals, steel and plastic pipes. The data are also given on the number of rectifier devices; conversion units and other specialized equipment.

For electrical installations, the main technical and economic indicators are calculated separately for the MEZ and the installation area. This section also contains information on issues resolved in the construction project. Here, if necessary, a protocol is made for the division of work with adjacent installation organizations (for example, in the installation of instrumentation and automation). The materials of the first part are primarily intended for planning, control and operational management of electrical work.

The second part covers the issues of organization and technology of works on the construction site. The object is divided into mounting areas, for example general lighting, power supply over 1000 V, trunk bus systems up to 1000 V (broken down by stages of construction), etc. Include the initial data for scheduling the work, recommendations for installation technology, the flow of goods, a list of mechanisms, devices, special tools and instruments. At the end of the second part, special instructions are given on safety and promsanitary practices, fire safety at performance of assembly and welding works, acceptance documentation.

The third part includes limit-completing lists for equipment and materials, electrical structures, assembly products, enlarged units and units. Summary specifications of the project for electrical equipment and materials during the development of the PPR are specified in the working drawings of the project and broken down by suppliers: the customer, general contractor, subcontractor.

The fourth part contains tasks of the IES. Provide a list of products with an indication of the number, cost and production time, as well as the calculation of labor costs for products and work, drawn from the drawings and sketches.

The fifth part consists of the calculation of labor costs and wages for the installation area with a summary table.

For large and technically complex objects, short directories are additionally compiled, which allow you to orient yourself in the documentation of the working project and on the construction site. They contain tables of volumes of the project with breakdown by sections and objects and a plan of the construction site. The plan identifies electrical facilities and facilities that have electrical devices, cable and air networks. Provide a single-line scheme of electricity supply, drawings of the location of equipment in electrical rooms, substations, workshops, the plan of bus lines and trolleys, power schemes for lighting panels. The separation of PPP materials into parts is explained by the practical expediency of using them during work in various subdivisions of assembly offices. For small and medium-sized objects, the PPR materials form a single volume, and for large and complex objects they are produced in parts.

For objects with a large volume of work and new technological solutions, the PDD develops technological maps that contain a plan for organizing the work with the installation of mechanisms, devices, installation routes and the procedure for performing technological operations. Provide a scheme of freight flow indicating the installation, unloading sites, openings and workplaces. The map contains a list of mechanisms, special devices for the production of work, the calculation of labor costs and wages. It gives a brief description of the mounted equipment: dimensions, weight, quantity and other information.

Depending on the nature of the facility and the conditions for the installation, the composition and sequence of materials in the PPR may vary, which is agreed with the line staff of the site, which is usually attracted to participate in the development of the project. The approximate composition of PPP is given in Appendix 1.

It should be noted that the type of work ahead influences the detailed elaboration of the individual sections of the PPR. So, for the installation of heavy buses, first of all, consider the technology of connecting the tires, the configuration of the blocks, the transportation issues, the presence of mounting openings, the construction of fastening along the road and protection at the intersections with the pipelines.

Detailed elaboration of organizational measures for performing work in reconstructed or expanded facilities, where work is carried out in the conditions of the operating enterprise. Specially develop technology for those works that represent complexity when they are performed due to lack of instructions and novelty of technical solutions.

The composition of the shortened PPR provides for sufficient completeness of the development of materials, except for documents, the presence of which in full PPR is due to the complexity and completeness of the work. In the shortened PPR, there are: bulletins for enlarged units and blocks, manufactured and assembled in the Ministry of Economic Development with the necessary drawings and sketches, a list of mortgages, holes and openings, agreed changes to the project, specifications for materials broken down by supplier, limit-picking statements for materials and equipment for the MEZ and the installation site, the initial data for the organization of work (labor costs and estimated cost), special requirements of the safety regulations. The list is attached to the PPR with a set of acceptance documents for the facility. In the PPR, references are made to the current regulations and rules.

For typical simple objects, the composition of the PPR is even more limited and concretized. For example, for a typical substation of a residential microdistrict, the order in the MEZ consists of four blocks: a block of 10 kV switchgears with KSO chambers, bushing insulators, a cable jumper or buses to a transformer and lighting mounted and fixed to chambers; a block of 0.4 kV switchgears from switchboards with electric equipment for electric power distribution, a busbar and an illumination board, a step-down transformer for supplying a network of repair lighting, and luminaires fixed on panels of a 0.4 kV panel; block lighting the camera transformer; block of grounding devices, including a barrier, posters, etc. With this preparation, the degree of the substation collection reaches 90%.

In addition to the single-use PPD for the projects under individual projects, typical PPDs are developed and applied. They are mainly used for standard objects and housing projects, the construction of which is conducted according to standard project documentation. In order to reduce the labor costs of engineering engineers in the development of individual PPRs, standard PPRs are used by type of work. They develop common questions specific to each type of work, which allows you to make links or use the finished materials when developing a PPR for a particular facility. In the CentroElektromontazh trust of the Mintmontazhspetsstroi of the USSR, a library of PPRs developed by the erection offices is being assembled. This allows you to accumulate experience in the preparation of works, use the best PPR as a sample in their development and as a reference in solving technical and organizational issues. Completed development of PPR is considered by the technical council, and after making additions and amendments they are approved by the chief engineer of management. Deviations from decisions made in the PPR are not allowed without the written permission of the chief engineer.

High-quality installation electrical wiring consists of several important stages. The first and most important stage is the drawing up of the electrical installation project, ideally, if the project is made up for all kinds of work with reference to furniture and household appliances. The second no less important stage is the miscalculation of the quantity of materials and the choice of quality electrical products from reliable suppliers. And the third major and most laborious stage is the immediate execution of the installation work, which in turn is divided into two stages:

High-quality installation electrical wiring consists of several important stages. The first and most important stage is the drawing up of the electrical installation project, ideally, if the project is made up for all kinds of work with reference to furniture and household appliances. The second no less important stage is the miscalculation of the quantity of materials and the choice of quality electrical products from reliable suppliers. And the third major and most laborious stage is the immediate execution of the installation work, which in turn is divided into two stages:

1. Performing the so-called "rough work", installing the installation holes and laying the cable;

2. Installation lighting devices, sockets and switches after completing the finishing work.

About nuances in drawing up the design of electrical installation works and the features of its compilation a little more in detail.

To draw up a project, you need to clearly represent the location of furniture and basic electrical appliances. In the kitchen you need to clearly represent the place of installation of the working surface, cooker, hood, oven, refrigerator and microwave, etc. So, for example, the fact that the sockets do not coincide with the actual arrangement of electrical appliances will lead to inconvenience when connecting, damaged appearance, while pulling wires along the furniture, and there is an additional danger of electrical shorts and fire, when using different extensions, especially when connecting powerful electrical appliances.

It is worth noting that all the powerful electrical appliances and sockets of the working surface are desirable to be connected to separate lines and circuit breakers. The refrigerator, although consumes relatively little power compared to other devices, but it can also be connected to a separate switch. This is convenient when leaving home, you can turn off all machines except the refrigerator.

In the kitchen, in addition to the aforementioned outlets for stationary electric consumers, it is also necessary to provide sockets above the work surface (table top) and one or two sockets for cleaning or other needs. As a rule, at least 3-4 outlets are placed above the working surface. This is due to a large number of electrical appliances in the kitchen. Also in the box with sockets above the countertop, you can put a switch on the work surface lighting, if it is provided in the lighting plan.

The lighting plan is calculated based on the area of the kitchen, work area and eating area, as well as electrical outlets for lED backlight furniture. The backlight is mounted from the bottom of the hanging cabinets and provides additional illumination of the working surface, as well as performs a decorative function.

When composing a project for a bedroom or a living room, as a rule, special attention should be paid to the location of the TV and the air conditioner for laying the necessary cables. The correct location of the sockets allows you to hide cables from the TV and other devices, both when you install the TV on the cradle, or when it is suspended. When you suspend the TV above the pedestal, you can use two rows of outlets, the bottom row serves to connect the tuners of the speakers and consoles, and is mounted behind the cabinet. And the top row of sockets is mounted behind the TV and includes a 220 V socket, Internet and TV, and one empty outlet that serves as a connecting channel between the top and bottom row for connecting additional wires. Accordingly, in the lower row, the same empty socket is made, and a pipe is laid in between them, into which the wires will subsequently be hidden. To connect the air conditioner, as a rule, the electrical wire is installed in the place of hanging the indoor unit, and when installing the air conditioner, the installer hides it inside the unit.

In addition, it is necessary to mount sockets for connection of other electrical appliances, for a vacuum cleaner and chargers, and in the presence of a warm floor, prepare a mounting hole and a wire for connecting the thermostat. To the opening for the thermostat, a corrugated tube is also fed, which descends to the place where the temperature sensor will be located. When connecting a WiFi router, you need to connect 220 V and "twisted pair" in the place of their installation. It should be noted that the cable for connecting the Internet must be routed from the installation site of each user's router to a separate wire. And lay the route of the Internet and TV cable laying separately from the power wires to avoid the appearance of interference from the electromagnetic field of electrical cables.

To connect the intercom, also draw electrical cable leads to power the device and a signal cable to connect the buttons and the camera with the microphone.

Separate attention deserves the design of wiring in the bathroom. Here you need to remember the increased humidity and, accordingly, the sockets and fixtures placed in places of high humidity should be installed waterproof. With regard to the placement of outlets and switches, the sockets should be provided for a razor or a hair dryer near the sink with a mirror. If an electric heated towel is provided, the socket must be located in the place where it is installed. It is also necessary to provide electrical leads of the wires to the vent for connecting the fan and for lighting the mirror over the sink. For convenience of inclusion, the switch for lighting the mirror can be mounted in one frame with a socket. And the main light switch in the bathroom and toilet is placed on the outside, it is advisable to have an idea of which way the door will open and place it on the other side of the canopies.

The location of the sockets in height often take 300 mm from the floor level to the center of the outlet, the sockets that are located above the bedside tables or are tied to other furniture are usually located on the basis of furniture sizes up to 100 mm from their surface. Switches are located at a height of 900 mm, if they do not have a peg to the furniture. Near the beds they are located below the usual level, and above the countertop in the kitchen and above the sink in the bathroom, respectively, higher.

For the convenience of turning on and off the lighting in long corridors, in large rooms and on stairs, usually there are passage switches at the beginning and end of the room, or at the bottom of the stairs and at the top. This allows you to manage the same chandelier or group of fixtures from different locations. If control from two places is not enough, you can install additional cross switches in the right amount.

As for calculating the protection of electrical appliances and automatically controlling them, everything here depends on the customer's preferences. But there are basic elements of protection that must be installed in each apartment. So the main device for protection against short circuits and overloading the wire is a circuit breaker or an "automatic". To protect against leakage currents in case of insulation failure, a residual current device or RCD is used, the differential automatic switch combines the functions of the above-mentioned devices. In addition, it is possible to install protection against internal overvoltages, most often - a voltage relay, adjusted to turn off the network for the specified parameters. In the presence of expensive equipment, you can also install a device for protection against external overvoltages (thunderstorms). Only if with protection from internal overvoltages everything is clear, then protection against external overvoltages must be carefully calculated based on specific conditions, because the varistors used in it are not the same and protect from different stress levels. And the installation of a varistor at random or approximately, will remain simply thrown away money by the wind.

Drawing up an electrical project, as well as choosing materials and completing electrical work, is a very important stage in any construction, which must be approached responsibly. Errors in the design and other stages are then poured into larger costs and troubles. Therefore, do not trust responsible matters to professionals and then everything will be fine !!!

Since he regretted calling an electrician-specialist, and called his friend, allegedly versed in the wiring, now I spit and regret whenever I turn on the kettle in the morning. Sockets were so ill-considered that you have to use an extension cord and always try not to touch it. In addition, last month, when the switch was short, I had to listen to a whole "ode" in the direction of my friend, who laid the wires in one place diagonally. Once again, you are convinced that the work needs to be given to specialists.

I do not agree with the fact that the refrigerator requires a separate machine. As a rule, when you leave, the refrigerator and so off from the network. Therefore, this proposal is controversial. With the rest I agree. As for cable wiring, even professionals make mistakes. For example, in new buildings under the "key" is carried out more subtle copper cables for furnaces and electrical appliances. This is done, because of the cheaper work.

You are right, on the building to reduce the cost of using a smaller wire, even if the marking is 2.5 mm2, in reality the thickness of the veins is less than 40%. and in the market when buying cheap cables, you can buy truncated or from an incomprehensible alloy that have not quite the same electrically conductive properties.

Usually, one sheet is sufficient for the development of the project. on which all points of connection, places of installation of fixtures, sockets and switches, boxes are indicated. On cable management, there are certain rules, usually they are laid on the walls at an altitude of 10-15 cm from the ceiling and always only vertically or horizontally, but not diagonally, as do some mountain installers.

On the article did not see a few details:

1) The author forgot about the switch boxes. How to where and in what quantity to put them. Yes, and why they are needed. This is important.

2) I do not agree with the refrigerator either. It is not particularly practical to take an entire automaton for it. where it is easier during the departure to remove all other consumers from the outlet. Under a separate machine, I would bring out the electric floors and the oven. I speak from personal experience.

3) My advice. Do not be too lazy to photograph the layout of the apartment. It is desirable with attached roulette on key places. Schematic diagram, but the correspondence perception is better.

4) And finally. Do not skimp on rosettes. Place where you can and you can not. Practice shows that they are always lacking.

Huge choice in the design and installation has a choice of sections installation wire, the power load must be observed. Yes, and for the bathrooms I agree, there are already requirements for IP to 54 no less, this is a home for people and there are many nuances on which to save yourself dearer will cost.

A lot of water.

You'd better write:

Vladimir33777

You are right, there is a lot of water, because the article was written to order.

With regard to the wire cross-section, there are tables of PUE where it is indicated which wire for which load, although there is still a dependence of the resistance of the wires on the length and heating, but who will take this into account if people write that 1 refrigerator is too much))

And about the machines themselves, it's extremely not right to select a submachine gun design load. The load is selected wire, and the machine is put to protect the wire from overheating. And if the copper wire is 2.5 mm2, then at least how much you connect electrical appliances to it, it's a crime to put more than 25A of the automatic machine! We usually put 16, because the normal 16 amp machine will withstand 20-22A 20-30 minutes. A 25 amp to 30A the same time. this is enough for short-term overloads, but the wire, as well as the sockets do not heat up to the critical temperature.

Regarding the issue on the distribution boxes, then put them on 1 piece for lighting and 1 for the sockets, at the level of the strob (the lower edge) can be displaced if it crosses the profile of the gypsum board ceiling. According to the rules, there should be access to the boxes, but I have never seen him make, weld, solder, check and gloss over for centuries. By lighting the box is made vertically above the switch and you will never guess whether you can drill there or not. for sockets, preferably above one of the outlets, based on the number of wires you need to pull from each + input. some rosettes can be plugged in for cheapening. In general, there are many ways, and how to do it for you.

A lot of water.

You'd better write:

- how to calculate the load per each outlet;

- the conductor of what section to lay (-with a hidden gasket (gypsum, etc.), with an external gasket in wooden house, when laying inside the wall under the plaster);

- what wire to use when laying from the pole to the machines;

- advantages and disadvantages of aluminum and copper wires;

- nuances with a section of copper and aluminum wire for laying on the same load;

- how to connect copper and aluminum ...

You can write many questions ...

If you are good at this, share your knowledge with others ...

Write for people and for the number of BukAf - different things.

P.S. From personal experience: A friend warms the socket when he turns on the lawn mower (who does not know - the power is 2800W).

The introductory automaton 32A (new) from which the bundle leaves four or five ALUMINUM wires, each section of 2-2.5 square and diverge throughout the house. One of them suits us. In it, an extender of the type "Pilot" is pushed into five! outlets and in them is connected: El. a water-heater (1,5 kW), a washing machine (2,5 kW), and another extender (20) is pushed into it (an extension of the pilot type), if not more meters, to which, on the street, a lawn mower is connected.

To the question: - Are you not afraid to burn? He replied: - Well, I changed the machine (and the machine is the only one), and the wires in my city are the same. Only he did not specify that in the city the wiring is done COPPER WIRE 2.5 squares, withstanding up to 6.5 kW load (BBGG), and not aluminum.

The person did not know and that at a choice of aluminum wire, its thickness, in comparison with copper, will be more approximately by 40% for the same load. Those. if you decide to put aluminum - take the next, larger diameter.

We take a load to lead for copper and if you were told that you need a wire of 2.5 squares, and you want to put aluminum, then for aluminum you need the next diameter we have produced, that is, 4 squares to withstand the same load.

As it all happened, but in a nutshell.

There will be time to write a NORMAL article about the wires and wiring.

1. "how to calculate the load per each outlet" - the sockets without grounding withstand current of 10 A (2.2 kW of active load !!!), with grounding type SCHUKO-16A (3,5 kW of active load !!!). That is, if you are going to connect low-power devices to a block of 4 outlets (up to 1 kW), then it does not damage either sockets or wiring with a cross section of 2.5 mm. If the power of one device is from 2.5 kW, it is recommended for him to install a separate automaton and lead to an individual outlet or directly to the device.

2. "- with a wire of the section to be laid (-with a hidden gasket (gypsum, etc.), with an external lining in a wooden house, when laying inside the wall under the plaster);" - most often for lighting, a cable with copper conductors of 1.5 mm square is used, for general purpose receptacles - 2.5 mm.kv., for powerful devices is calculated individually (in the passport for the device, the recommended cross-section of the cable is sometimes spelled).

3. "- what wire to use when laying from the pole to the machines;" - for laying from the pole to the machine, the most commonly used is SIP-4 2 * 16 or SIP-4 4 * 16. However, the cross-section can be increased based on the capacity and the length of the line from the power line to the accounting board.

4. "- advantages and disadvantages of aluminum and copper wires;" - Aluminum has the only advantage - low price.

5. "- nuances with the cross-section of copper and aluminum wire for laying on the same load;" - here it is necessary to take into account the throughput of copper and aluminum, as well as various active resistances of these materials.

6. "- how to connect copper and aluminum ..." - using the Wago terminals

Regarding your PS:

1. I went to the site of Bosch - lawnmowers at them with a capacity of 1.2-1.8 kW (5.5-8.2 A). In addition, this device does not work constantly.

2. For a long time allowable current for cable with plastic insulation and aluminum conductors - 21 A (GOST 31996-2012). Based on this, the machine is not selected correctly. Should have been at 20 A.

3. Boiler with a capacity of 1.5 kW (6.8 A). It does not work constantly, only at the time of heating or full heating of the tank. Not all power is used during heating.

4. A washing machine with a power of 2.5 kW (the old one is probably of class D, current 11.4 A). This power will consume only with the included TEN at 90-95 degrees Celsius.

If you take into account that for some reason all these devices will work together for an hour, then for the wiring this is certainly bad (overload of 26%), but not critical. The machine would even be standing at 20 A, it would still keep such a load for an hour.

All good mood, and do not skimp on quality wires and accessories, because this once and for always, better than a sausage a month not to eat))))

1. "With regard to the cross-section of the wires, there are tables of PUE, which indicates which wire for which load, although there is also a dependence of the resistance of the wires on the length and heating" - the wire cross-section must be selected based on GOSTs, not PUE. Since the PUE 7 indicates the averaged data (verify the data of the tables PUE and GOST 31996-2012). Active resistance should be taken into account on long routes (more than 100 m), and such basically does not happen in private houses and apartments. Consider the "dependence of heating" when laying the cable in a monolithic wall is not necessary (see GOST 50571.5.52-2011).

2. "And about the machines themselves, it is extremely improper to select an automatic machine for the design load." - open the PUE "3.1.4. The rated currents of the fuse-links of the fuses and the currents of the settings of the circuit-breakers serving to protect the individual sections of the network should in all cases be chosen as small as possible according to the design currents of these sections or at the rated currents of the electric receivers, but in such a way that protection devices did not disconnect electrical installations during short-term overloads ( starting currents, peaks of technological loads, currents at self-start, etc.). "You contradict the requirements of the PUE!

3. "We usually put 16, because the normal 16 amp will withstand 20-22A for 20-30 minutes." - The 16A machine will work at a load of 1.45In for 20-60 minutes (see time-current characteristics of automata), but this is not its normal mode of operation. The recommended operating mode is an overload of 1.13 In.