Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

Plug-in sockets today are an integral part of almost any power network. To their main task, many include communication electrical appliance through the plug. They are considered quite common and that's why everyone needs to know what they are for and how to install them.

In this article you will find detailed information about their design, as well as how to install without violating the installation rules.

Often socket consists of three main elements:

- Housing.

- Block.

- Contact with the device.

- The body is the protective part of this device. Enough often performs not only decorative, but also protective function. Quite often, many manufacturers make an outer cover of durable material. If necessary, the body can be easily zadekorirovat under any interior.

- The socket is the base of the device. When it is made, ceramics are often used. It holds not only the cover, but also the protective contacts.

It is important to know! Ceramics - it's quite a fragile material and therefore work with it should be as carefully as possible.

- Contact with the device is a contact, through which electricity reaches consumers. They are usually made of various alloys that have a degree of elasticity.

Classification of plug sockets

Usually, plug sockets are classified according to several criteria. Here are the main types of their classification:

By type of construction:

- Hidden installation. It is used only for internal wiring. To install, you need to load it into the wall. In this case, the protective housing must be in the box and not protrude out of it. The wires in it should be connected in such a way as to prevent their extrusion.

- Outdoor installation. Typically, specialists use it for external installation. Mount it directly to the wall. Quite often, their design involves the use of a special backlight or protective box.

- Pluggable. In this device, the protective contact must be connected to the ground wire. Quite often it is popular only if you have a ground in your house. Special sockets for the pin are located slightly below the hole itself. Usually they are used for electric cookers.

- Sockets without grounding. Most devices belong to this type. They are suitable for almost any wiring.

On the level of protection from moisture:

- Waterproof devices must be installed in rooms that contain a large amount of moisture. Thus, you can reliably protect your device. Here, the developers have provided a protective membrane, which acts in the role of protection against moisture. Quite often, waterproof outlets are installed externally.

A socket outlet is one of the components electrical network, without which the task of connecting devices is significantly complicated. Despite the large number of existing models (waterproof, dual, grounded), the basic principle remains unchanged. Indeed, the socket outlet makes it possible at a minimal cost to provide a safe connection to the network of electrical appliances to any person, even without a tolerance group.

Part of the whole

Although the plug socket is a structurally completed device, it can not be fully operated without the plug, which it creates with copper sliding contacts. In other words, it's important to match the solutions used. For example, a socket outlet for two sockets (holes) is intended for a suitable plug with the same number of pins (pins), with the diameter not exceeding the allowable value.

Popular Modifications

Let's consider, what features are inherent in the sockets, used in household electric systems. One of the key differences is the body material (not to be confused with the outer cover). The socket can be made of ceramic or non-flammable plastic. The latter, despite its high performance characteristics, loses its resistance to heat (it deforms at high temperatures, caused, for example, by poor contact compression) and the permissible breakdown voltage (the best insulators are glass and ceramics, not polymers).

Let's consider, what features are inherent in the sockets, used in household electric systems. One of the key differences is the body material (not to be confused with the outer cover). The socket can be made of ceramic or non-flammable plastic. The latter, despite its high performance characteristics, loses its resistance to heat (it deforms at high temperatures, caused, for example, by poor contact compression) and the permissible breakdown voltage (the best insulators are glass and ceramics, not polymers).

Now, when everywhere replacing obsolete home postings, the plug socket with grounding contact becomes irreplaceable. If in the Soviet era the standard was a two-wire network (zero and phase), now, according to the requirements of the PUE, a third grounding wire is mounted and additionally diluted. This significantly increases electrical safety. It is connected to a special contact in the sockets. The equipment providing the use of grounding is realized with special plugs, in which the case is connected to the third contact. When you turn on the plug, there is a contact not two, as before, but three wires. Such outlets can be of two modifications: when the plug has three pins, standardly included in the holes, and also (more convenient solution) in the presence of a spring-loaded sliding contact, which additionally fixes the included plug. The peculiarity of the latter is that, when switched on, first a grounding circuit is created, and then deepened power conductors.  In retail chains, you can find sockets of a special design, in which the holes are closed with plastic curtains, which need to be pushed with pins to insert the plug.

In retail chains, you can find sockets of a special design, in which the holes are closed with plastic curtains, which need to be pushed with pins to insert the plug.

Installation of plug sockets

There are models for the external (open) and internal first type, usually used in conjunction with external wiring, in which the wires are not hidden in the wall, but fixed to small insulators or placed in cable channels. Usually these are production premises, sheds, street chains. If the lower part of the socket is not equipped with a closing cover, then a plate of non-conductive material (textolite, wood) must be fixed to the substrate. Then disassemble the socket housing and use screws or bolts to place it on the prepared site. Wires can be connected both before and after installation (always in the de-energized state of the network).

The models for the concealed installation are equipped with internal metal "paws" which, when twisting the two screws, are bent to the sides, securely fixing the entire structure inside. The installation is simple: a hole is prepared in the wall, the diameter and depth of which correspond to the selected plastic box; then a channel is made for the wire from the main line; The ends of the wires are connected to the sockets for this purpose; the fixation is performed; the outer cover is installed.

The internal electrical network of any building, space consists of wiring and wiring accessories. These include electrical boxes, power and signal sockets, switches and switches, dimmers (dimmers). A socket outlet is the most common type of electrical installation products. Socket outlets are designed to connect individual electrical appliances to a household electrical outlet by means of a plug.

Socket construction

There are many types of plug sockets, but they all consist of the same set of structural elements:

- a shoe (at models for external installation it is fastened on the basis of the case);

- working contacts;

- protective cover (cover).

Pads are made of dielectric materials that do not conduct electric current. This is a thermoplastic, polycarbonate, ceramics. Ceramic pads best meet the requirements of fire safety, but this is too fragile material, so now mainly make plug sockets with plastic pads. Work contacts are thin metal plates, which are attached to the shoe by a screw or spring connection. The contacts are connected by means of clamps power cable, when the pins of the plug are in contact with them, the current feeds the appliance.

The closer the plugs of the plug to these contacts, the higher the quality of the product. Therefore, copper and its alloys are used to make working contacts, from which sufficiently elastic plates are obtained. The technical characteristics of the contacts determine the maximum current that the socket can withstand, and the total power of electrical appliances that can operate on it. The body closes the contacts, makes it impossible to touch them accidentally, and at the same time performs a decorative function.

Types of sockets

First, we'll figure out what a plug-in power outlet is and how it differs from a low-current one. Power socket outlet is an electrical installation product with connectors under the plugs of the plug, intended for connection to the electrical appliance network. Products of this category vary in scope and characteristics:

- for alternating current networks (rated current 16 A) and constant (10 A) current;

- household (220 V) and industrial (220 and 380 V).

Low-current systems are designed for low-current networks, which carry information currents low voltage (12 or 24 V), the current is measured in milliamperes. They are also called signal and are divided into computer, telephone, television, multimedia, acoustic.

Sockets are classified according to a number of characteristics:

By the way of installation:

- internal (hidden installation) are connected to the hidden wiring, they are heated into the wall, they are usually mounted using the installation box;

- external (outdoor installation), mounted on top of the wall using a padding or gasket;

- modular (for mounting on DIN-rail).

The external installation of plug sockets is simpler, but such models protrude strongly from the wall, which is not always convenient.

By electrical diagram:

- two-contact (without grounding);

- three-contact (with grounding), provide protection from electric shock as a result of a breakdown on the body of the appliance

A three-pin socket outlet is a product that is only relevant in homes and apartments where the network has a ground wire that connects to the ground terminal. In most apartment buildings in the post-Soviet space, the organization of the grounding system was taken care of only in the last years of the last century. So in the old apartments to install three-pin sockets is meaningless, except that the preliminary reconstruction of the network in the scale of the apartment.

In terms of the number of pads, the most common options are single (single) and double (two-seater) sockets, there are fewer triples, quadruples and even five-seat ones. How many pads, so many pairs of plug connectors, therefore, so many electrical appliances can be connected at the same time. A pair of connectors are usually parallel to or perpendicular to the ground, less often at an angle of 45 °. The configuration of the connectors corresponds to the configuration of the plug pins, it differs a great variety, different countries have their own standards. We often have such varieties:

- domestic standard - cylindrical pins with a diameter of 3.5 mm;

- eurostandard - cylindrical pins with a diameter of 4.5-5 mm;

- american standard - flat pin-plates.

The rosettes differ in their design, design features, and the presence of additional elements. In the bathroom and other rooms with a high level of humidity, devices with a hydraulic barrier (membrane, rubber rings) are used, which prevents the penetration of water to the contacts, and with an internal flange for evacuation of moisture. Sealed models are in demand in the private sector, where it is often possible to install plug sockets and switches outside the house, and it is necessary to protect them from precipitation, pollution. They usually have a cover that can be spring loaded, but the presence of a cover does not mean an increased degree of dust and moisture protection.

Families with young children often purchase sockets with curtains. This is a protective device, thanks to which the child can not put a nail or fingers into the connector. Curtains are pivoting and rising (spring-loaded), they cover the connectors, and open only under the pressure of the fork pins, both at the same time. If the plug comes in rather tight, and the outlet is often used, it loosens in its nest. To prevent such situations, devices with a fork-eject button are released. Ideal for connecting high-capacity appliances such as a washing machine, a boiler in a damp environment, a socket outlet is a model with a built-in residual current device (RCD).

When choosing an outlet, you must first pay attention to its specifications: rated current and its type (constant or variable), rated voltage, degree of protection (IP20 - normal, IP44 - dust-proof), presence-absence of grounding. These characteristics should be correlated with the parameters of the network, the purpose of the product. Design and minor design features (ejector, backlight, cover) also matter, but not so important.

Installation order

The installation of plug sockets, regardless of the method of installation, must be carried out with the power disconnected, and you should always use an indicator screw or a tester (multimeter) to make sure that there is no voltage.

- Under internal outlet in the wall a hole is hollowed out.

- There insert the installation box, pass the ends of the wires into its holes.

Socket outlets are electrical installation products and are an integral part of any electrical network. In everyday life various types of plug sockets are used, the choice of which depends on many factors.

Let's consider the main types of sockets, the features of their use and installation.

Socket Outlet Design

A socket outlet is an ordinary socket that is in every house and without which the work of most household appliances is impossible. The main task of the device is the communication of an electrical appliance through a plug with an electrical network.

The plug socket consists of three main elements:

- protective casing;

- block;

- contact.

The socket housing performs decorative and protective function - it closes access to current-carrying elements.

The protective case can be single and double. If it is necessary to install more than two paired sockets, it is necessary to install separate sockets with a plastic core in the common sockets frame.

The outer cover of the connector is made of unbreakable, heat-resistant plastic. The case can be zadekorirovat under the interior of the room. Some models of sockets are equipped with additional devices: protective covers and curtains, backlight, push button for ejecting the plug.

The base of the device is a shoe, the element on which the cover and contacts of the socket outlet are held. The material of the pads is ceramic or carbolite.

Carboline rosettes are more durable, but the shoe from this material, mainly found in old samples of sockets.

Ceramics - a very fragile material, so when installing the outlet you have to act as carefully as possible, - the damaged shoe can not be restored

The socket can be used for installation of open and hidden installation sockets, as well as serve as a blank when the extender is made independently.

The working element of the outlet is a contact through which electricity is transmitted to consumers - household appliances.

With the help of key or screw terminals, the contacts on one side are connected to the power conductor, and on the other hand - they interact with the plug of the appliance.

Contacts are made of metal alloys, which have a certain degree of elasticity. This property is necessary for the reliable connection of the socket with the plug pins.

The density of contact of the petals of the contact to the plug is one of the indicators of the quality of the plug socket

Technical characteristics of contacts modern outlets exceed the performance of old samples. The permissible current strength of the new outlets is 10-16 A, and the old ones 6.3-10 A. These values determine the total power of electrical appliances that can be operated from the outlet.

Classification of plug sockets

Sockets are classified by several criteria.

By type of construction:

By electric scheme:

According to the level of water resistance:

By the number of pads:

Self-assembly of the socket

General rules for installing outlets

Before starting work on the installation of the socket outlet, it is absolutely necessary to disconnect the mains power supply and check the voltage by the indicator

Installation of a hidden type socket outlet

Consider step-by-step connection of the socket:

Installing an external type outdoor plug socket

Plug-in socket connection open installation - a simpler and faster method. This option applies if the house electrical wiring - external.

Sequence of installation works:

Requirements for the number and quality of plug sockets

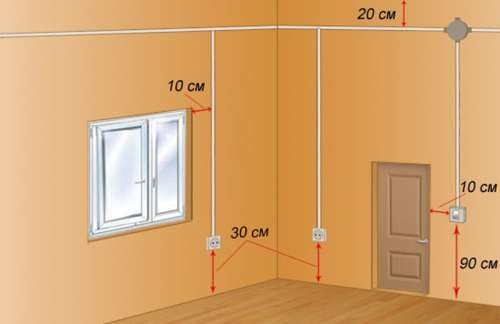

When installing and setting up electrical devices, it is necessary to observe the approved standards that determine the number and type of outlets depending on the design and room characteristics:

The housing of the socket must be marked (IP44, IP22, etc.), indicating the degree of protection of the device from foreign objects and moisture

The first digit in the marking indicates the diameter of the objects from which the housing is protected, and the second - the level of moisture content.

Allocate the following degrees of protection:

- Protection from touching foreign objects with current-carrying elements:

- 0 - no protection;

- 1 - more than 50 mm, for example, the back of the hand;

- 2 - more than 12.5 mm - finger protection;

- 3 - more than 2.5 mm - protection against penetration of hand tools;

- 4 - more than 1 mm - protection against small bolts, nuts, individual conductors;

- 5-6 - complete protection against unwanted contact, dustproof housing.

- Degrees of moisture insecurity of outlets:

- 0 - no protection;

- 1 - protection against drops falling on the body vertically;

- 2 - protection against drops falling at an angle of 150 °;

- 3 - protection against rain;

- 4 - protection from various sprays, regardless of their direction;

- 5 - protection from water jets - the highest degree of protection.

For ordinary living room, the IP20 sockets are suitable, for the bathroom - IP44

So, when choosing a socket outlet, it is necessary to take into account such criteria:

- Type of electrical wiring in the apartment (outdoor or hidden).

- Operating nominal data of the socket (size and type of current (constant, variable), voltage in the network).

- Presence of a grounding loop.

- The location of the outlet (necessary for selecting the degree of protection).

A quality outlet should be made of non-combustible materials, ensure reliable contact and insulation of live parts

The selection and installation of plug sockets is a crucial stage in the arrangement of the electrical wiring of the room. A competent approach to the selection of the outlet, and the installation that meets all the safety requirements, will significantly extend the life of the electrical installation product and household electrical appliances.

A socket outlet is one of the main components of electrical plug-in connections. It is designed for quick connection and shutdown of electricity consumers with a capacity of up to several kilowatts.

Kinds of plug sockets

In most cases, they are made in two-contact and three-contact design, they are divided into internal and external wiring according to the design, with earthing and without earthing, according to the degree of waterproofness, to waterproof and ordinary ones. In addition, in some cases, the inside can be installed.

In most cases, it consists of a ceramic base, to which the bronze contacts are fastened by screws, holding the corresponding plug pins of the plug. Contacts have special areas, to which screws are screwed conductors, to which the lead wire is divided. Grounding contacts of the sockets, if they are provided, are made in the form of spring-loaded metal strips on both sides, into which a plug is inserted.

Differences between plug sockets

By appearance a two-pin socket with grounding immediately differs from the usual much larger depth of the connecting part - about 20 mm against 5 mm in the usual. The three-contact can be symmetrical and asymmetrical with flat or round contact holes. There are no side strips and the grounding contact is in front of the middle hole. The unbalanced socket does not allow inserting the plug incorrectly and interchanging the zero and phase conductors inside the connected appliance.

If the socket is designed for, the ceramic base is placed in the plastic housing, which is attached to the wall with the help of a special base - podrozetnik.

The socket for the external enclosure does not have and is mounted in a special recess, in  most cases of a cylindrical shape. To fix the ceramic base in the recess, on the outside of the base, there is a bracket with movable legs on both sides, the position of which is fixed with screws. This design allows you to fix it at a niche diameter of 65 - 75 mm. Then, with the help of a central screw with M2 thread, an outer panel, mainly plastic, with holes for the plug contacts is put on it. The distance between the centers of the holes for the two-contact hole is 19 mm.

most cases of a cylindrical shape. To fix the ceramic base in the recess, on the outside of the base, there is a bracket with movable legs on both sides, the position of which is fixed with screws. This design allows you to fix it at a niche diameter of 65 - 75 mm. Then, with the help of a central screw with M2 thread, an outer panel, mainly plastic, with holes for the plug contacts is put on it. The distance between the centers of the holes for the two-contact hole is 19 mm.

Sockets can be equipped with devices that prevent children from sticking foreign objects / penetration of insects. Usually it is a spring-loaded non-conductive plate, which can be moved only by the plug itself.

Installation of plug sockets