Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

SMD ( Surface Mounted Device), which in English means "surface mounted device". In our case, the surface is a printed circuit board.

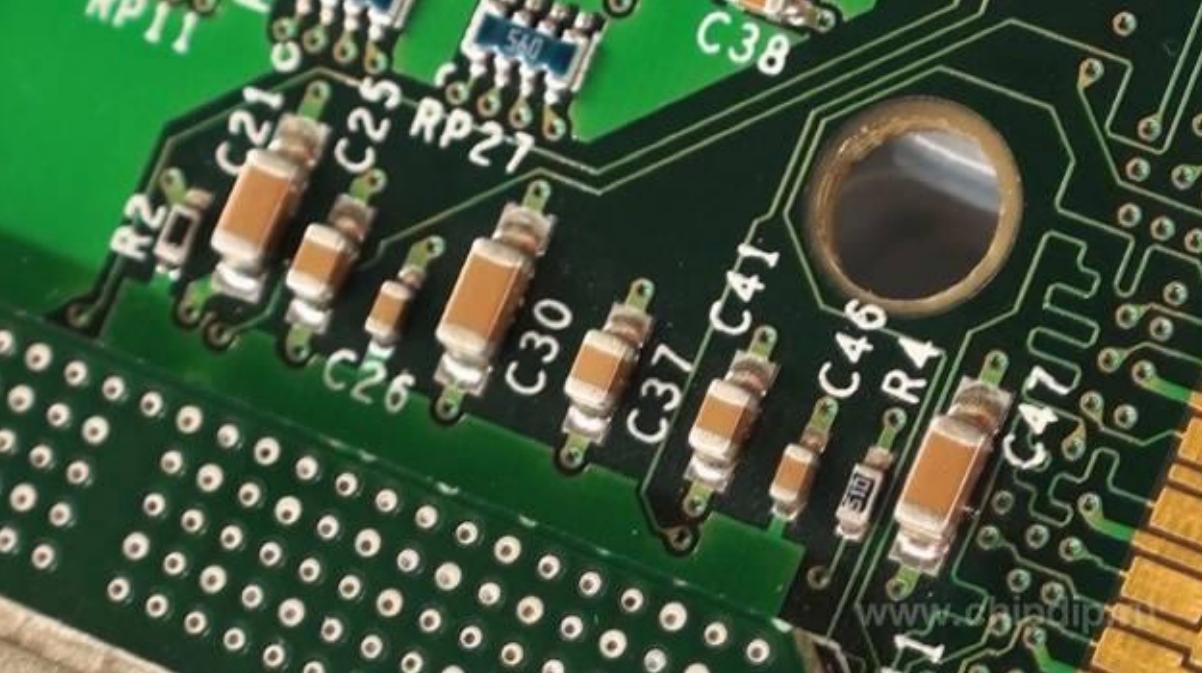

Here on such printed circuit boards are established SMD components. SMD components are not inserted into the holes of the boards, they are sealed on the contact tracks (I call them patches), which are located directly on the surface of the printed circuit board. In the photo below are pewter contact pads on the mobile phone's board, after all SMD components have been removed.

In our turbulent age of electronics, the main advantages of an electronic product are small dimensions, reliability, ease of installation and dismantling (disassembly of equipment), low power consumption and convenient usability ( from English - Ease of use). All these advantages are in no way possible without the technology of surface mounting - SMT technology ( Surface Mount Technology), and of course without SMD components. But why? Let's take a closer look at this issue.

The most important advantages of SMD components are, of course, their small size. In the photo below, simple resistors and SMD resistors.

Due to small dimensions, it is possible to place more SMD components per unit area than simple ones. Consequently, the density of the installation increases and, as a result, the dimensions electronic device. And since the weight of an SMD component is many times lighter than the weight of the same simple component, the mass of the radio equipment will also be many times lighter.

SMD components are much easier to evaporate, for this we need a soldering station with a hairdryer. How to solder and solder SMD components, you can read in the article How to solder SMD correctly . Sealing them is much more difficult, in the production of them have on the printed circuit board special robots. Manually in production, no one seals, except for radio amateurs and radio equipment repairmen.

Since the equipment with SMD components is very tightly mounted, the tracks in the board should be larger. But the tracks do not fit on one surface, so the printed circuit boards do multilayered. If the equipment is complex and a very high density of mounting components, then consequently there will be more layers in the board. It's like a layered cake made from cakes. This means that the printed tracks connecting the SMD components are located right inside the board and can not be seen at all. An example of multi-layered boards is a mobile phone card and a computer or laptop computer card (motherboard, video card, operative). In the photo below, the blue board is Iphone 3g, the green board is the motherboard of the company.

![]()

All radio equipment repairmen know that if the card is overheated, it is blown up by a bubble. With this interlayer communication torn and the board comes full ass without any recovery. Therefore, the main trump card when replacing SMD components is the right temperature.

Some boards use both sides of the PCB, while the density of installation, as you understand, is doubled. This is another plus of SMT technology. Oh, yes, we should also take into account the fact that the material for the production of SMD components is several times less, and their cost in mass production in millions of pieces is, in the literal sense, costing a penny. In short, some pluses :-). But, since there are pros, then there must be some cons ... But they are very insignificant, and we are not really concerned with you. This is an expensive equipment and technology for the production and development of SMD components, as well as the accuracy of the soldering temperature.

What all the same use in their designs? If you do not tremble hands, and you want to make, say, a small radio, then the choice is obvious. But still, in radio amateur designs, the dimensions do not really play a big role, and soldering massive radio elements is easier and more convenient. Some radio amateurs use both that and another mixed ;-).

Let's look at the basic SMD elements used in our modern technologies. Resistors, capacitors, inductors with low ratings, fuses, diodes and other components look like ordinary rectangles.

On boards without a circuit it is impossible to guess whether it's a resistor, or a condder or a horse-radish understand that. On large SMD elements, still put the code or numbers to determine their characteristics and parameters. In the photo below, these elements are marked in a red rectangle. Without a circuit on the device it is impossible to tell what kind of elements it is.

The sizes of SMD components can be different. It depends on the technical characteristics of these components. Basically, the larger the component's denomination, the larger it is in size. Here is a description of the sizes for resistors and capacitors. For example, rectangular SMD Capacitor yellow color. They are also called tantalum or simply tantalum:

And this is what SMD transistors look like:

There are also types of SMD transistors:

The coils of inductance, which have a larger denomination, look like this in the SMD version:

And, of course, as without microcircuits in our age of microelectronics! There is a lot of SMD types of Chips , but I divide them mainly into two groups:

1) Mikruhi, whose terminals are parallel to the printed circuit board and are on either side or along the perimeter.

2) Mikruhi, whose conclusions are under the mikruha itself. This is a special class of microcircuits, called BGA (from English Ball grid array - an array of balls). The conclusions of such chips are simple solder balls of the same size. In the photo below, the mikra itself, and its reverse side, consisting of ballpoints. BGA chips are convenient for manufacturers because they save a lot of space on the PCB, because there can be thousands of such balls under some mikruha BGA, which greatly facilitates the life of the manufacturers, but does not make life easier for the repairmen :-).

You can talk a lot about SMD technology and components. In this article, I outlined basically a superficial overview of the world of SMD components. Every day new mikruhi and components are developed. Less, thinner, more reliable. Some novice electronics engineers are indignant: "What kind of thing do we need at the school, at the university, or somewhere else, about Soviet transistors or old Soviet diodes, why do we need this, because now is the age of microelectronics?" Here they are mistaken ... Diode, it and in Africa a diode, though SMD, though Soviet, the difference - in dimensions. But it will work just like the Soviet one. Just know that microelectronics is from the word "micros", which means "small" from Latin, but the laws of electronics are everywhere the same, that in a large radioelement, in a tiny SMD.

Directories on SMD

SMD - Abriviate from English, from Surface Mounted Device -The device is mounted on the surface, ie on a printed circuit board, namely on special contact pads located on its surface. The use of SMD components can significantly reduce the size and weight of any radio amateur design.

The guide contains information on the decoding of codes for more than 34 thousand microcircuits, diodes and transistors, the switching circuits are given and a convenient information retrieval system

Extremely useful directory in the radio amateur library, with a very understandable search, contains information on almost all active radio components of microcircuits, transistors, diodes and others, including SMD.

Because of their very small gaboritov, many novice radio amateurs have the question "How to solder SMD?". In this short article, we were asked to answer this question in a practical example.

About SMDBut there are disadvantages, first soldering SMD components, the process is interesting and requires basic skills and experience. Secondly, if SMD used in multi-layer printed circuit boards, and located inside the latter, fails to change it simply is not possible. And when dismantling and replacing surface radiocomponents, it is necessary to strictly observe the temperature regime, otherwise damage to the internal structure can not be avoided.

Externally, SMD radio elements look like small rectangles with a code or numeric designation. And only on them and you can understand what it is: a resistor, a capacitor, a transistor or a microcircuit. The SMD component in modern electronics can be any radio element. On very small SMDs, the code mark can be completely absent, in this case only the schematic or the service manual will help to indicate the element. The appearance of a printed circuit board with various SMD radio components is shown in the figure below:

We have already got acquainted with the main radio components: resistors, capacitors, diodes, transistors, microcircuits, etc., and also studied how they are mounted on a printed circuit board. Once again, we recall the main stages of this process: the outputs of all components are passed through holes in the printed circuit board. After that, the conclusions are cut off, and then with reverse side The boards are soldered (see Fig. 1).

This already known process is called DIP-editing. Such installation is very convenient for beginning amateur radio operators: the components are large, they can be soldered even with a large "Soviet" soldering iron without the aid of a magnifying glass or a microscope. That's why all Master Kit kits for self-soldering involve DIP-installation.

Fig. 1. DIP-installation

But DIP-installation has very significant drawbacks:

Large radio components are not suitable for the creation of modern miniature electronic devices;

- output radio components are more expensive in production;

- The PCB for DIP-mounting is also more expensive due to the need to drill a number of holes;

- DIP-installation is difficult to automate: in most cases, even on large plants for the production of electronics installation and soldering of DIP-parts must be done manually. It is very expensive and long.

Therefore, DIP-installation in the production of modern electronics is practically not used, and the so-called SMD-process, which is the standard of today, came to replace it. Therefore, any radio amateur must have at least a general idea about it.

SMD mounting

SMD (Surface Mounted Device) is translated from English as a "surface mounted component". SMD components are also sometimes called chip components.

The process of mounting and soldering the chip components is correctly called SMT-process (from the English "surface mount technology" - the technology of surface mounting). It's not entirely correct to say "SMD-editing", but in Russia such a variant of the name of the technical process has taken hold, that's why we will speak the same way.

In Fig. 2. shows the section of the SMD-board. The same board, made on DIP-elements, will have several times the large dimensions.

Fig.2. SMD installation

SMD mounting has undeniable advantages:

Radio components are cheap in production and can be as small as they please;

- printed circuit boards are also cheaper due to the lack of multiple drilling;

- installation is easy to automate: installation and soldering components are made by special robots. Also, there is no technological operation such as trimming of terminals.

SMD resistors

Getting to know the chip components is most logical starting with resistors, as with the simplest and most massive radio components.

The SMD resistor is similar in its physical properties to the "normal", derivation variant we have already studied. All of its physical parameters (resistance, accuracy, power) are exactly the same, only the case is different. The same rule applies to all other SMD components.

Fig. 3. Chip Resistors

Sizes of SMD-resistors

We already know that the output resistors have a certain grid of standard sizes, depending on their power: 0,125W, 0,25W, 0,5W, 1W, etc.

A standard grid of sizes is also available for chip resistors, only in this case the size is designated by a code of four digits: 0402, 0603, 0805, 1206, etc.

The main types of resistors and their specifications are shown in Fig.

Fig. 4 Basic sizes and parameters of chip resistors

Marking of SMD-resistors

Resistors are marked with a code on the case.

If there are three or four digits in the code, then the last digit means the number of zeros, Fig. 5. The resistor with the code "223" has such resistance: 22 (and three zeroes on the right) Ohm = 22000 Ohm = 22 kOhm. The resistor with the code "8202" has a resistance: 820 (and two zeroes on the right) Ohm = 82000 Ohm = 82 kOhm.

In some cases, the lettering is alphanumeric. For example, a resistor with code 4R7 has a resistance of 4.7 ohms, and a resistor with code 0R22 is 0.22 ohms (here the letter R is a separator character).

Resistors of zero resistance, or resistors-jumpers are also encountered. Often they are used as fuses.

Of course, you can not memorize the code system, but simply measure the resistance of the resistor with a multimeter.

Fig. 5 Identification of chip resistors

Ceramic SMD-capacitors

Externally, SMD-capacitors are very similar to resistors (see Fig.6.). There is only one problem: the capacity code is not applied to them, so the only way to determine it is to measure with a multimeter that has a capacitance measurement mode.

SMD capacitors are also available in standard sizes, usually similar to the size of the resistors (see above).

Fig. 6. Ceramic SMD-capacitors

Electrolytic SMS-capacitors

Fig.7. Electrolytic SMS-capacitors

These capacitors are similar to their derivation counterparts, and the marking on them is usually obvious: capacitance and operating voltage. A strip on the "cap" of the condenser is marked with its negative terminal.

SMD-transistors

Fig.8. SMD transistor

Transistors are small, so write their full name is not obtained. They are limited by code marking, and there is no international standard for designations. For example, the code 1E can denote the type of transistor BC847A, or maybe some other one. But this circumstance absolutely does not bother either producers or ordinary consumers of electronics. Difficulties can arise only during repair. Determine the type of transistor installed on a printed circuit board, without the manufacturer's documentation for this board is sometimes very difficult.

SMD-diodes and SMD-LEDs

Some diodes are shown in the picture below:

Fig.9. SMD-diodes and SMD-LEDs

On the body of the diode, the polarity in the form of a strip nearer to one of the edges is necessarily indicated. Usually, the strip marks the output of the cathode.

SMD-LED also has a polarity, which is indicated either by a point near one of the leads, or some other way (for details see the manufacturer's documentation for the component).

Determine the type of SMD-diode or LED, as in the case of a transistor, it is difficult: a low-information code is stamped on the diode body, and on the LED body, there are usually no marks, except for the marking of the polarity. Developers and manufacturers of modern electronics take little care of its maintainability. It is understood that the repair of the circuit board will be a service engineer who has complete documentation for a particular product. In this documentation, it is clearly described where the component is located in the printed circuit board.

Installation and soldering of SMD components

SMD-installation is optimized primarily for automatic assembly of special industrial robots. But amateur radio amateur designs can also be performed on chip components: with sufficient accuracy and care to solder parts the size of a rice seed can be the most common soldering iron, you only need to know some subtleties.

But this is a topic for a separate big lesson, so more details about automatic and manual SMD-installation will be told separately.