Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

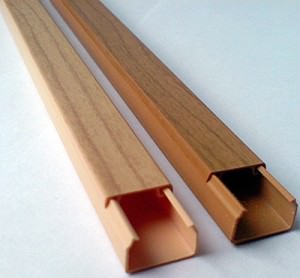

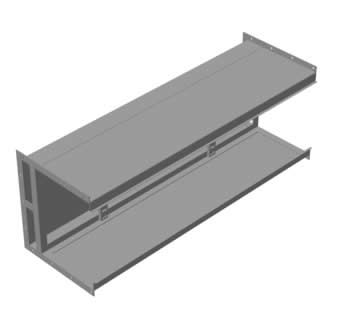

Plastic box, cable duct, wiring box - a detachable product with a rectangular cross section. It is made in the form of a long box structure with a flat base.

It consists of a base and a removable cover. Fixation of the latter, on the main box, is carried out by means of lateral fastenings having the appearance of beveled L-shaped grips.

Designed for laying one or several wires - from mains voltage, television, to the Internet, etc.

Varieties and scope

Scope and need of plastic boxes for wiring:

- The laying of the cable channel is used in all residential, office, public and industrial premises.

- There was a need to extend new connections, for example, a security alarm wire.

- Laying is carried out independently, without involving third-party organizations.

- The economic component - the cost of material and the cost of assembly work in the aggregate allow you to obtain a solid economy of financial resources.

- The use of cable channels allows you to quickly and easily access the laid wires - it is enough to remove the top cover in the right place.

- Cabling through the boxes can save considerable time during installation work.

It is also carried out when it is impossible to perform work on the installation of a rod for laying wires:

- finished finishing activities;

- there is a significant number of cables in the cross section;

- the room is finished with wooden material, faced with plasterboard or tile, it has metal surface etc.;

- the wiring has a temporary appointment;

- there is no necessary amount of time to carry out work on the execution of the strobes and their subsequent sealing;

- the inability to interrupt the work process in a room or conduct work associated with the formation of a sufficiently large amount of dust and loud sound, for example, in educational or medical institutions;

Depending on the purpose and the place of application, the box can be divided into several groups according to the form (section):

- rectangular section of the cable channel;

- square shape;

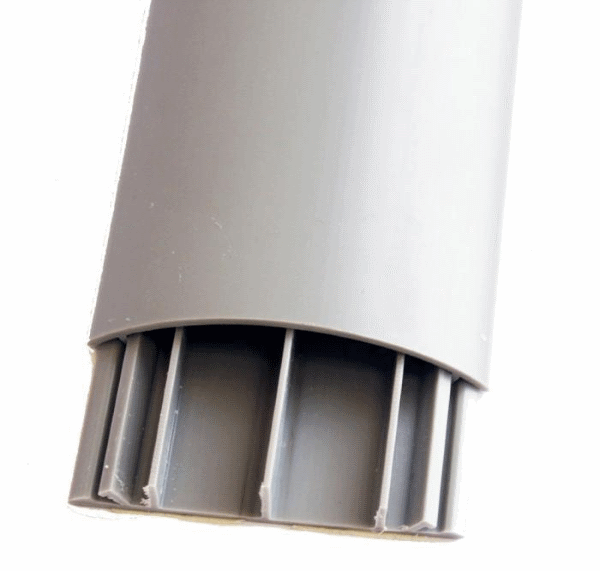

- semicircle (oval) with a flat base;

- triangles with different sides (equilateral or isosceles);

Types of cable channels

Ceiling arrangement of the box

Applied when laying the wire on the ceiling. Are intended for networks for electric lighting, security alarm systems or ventilation. Mounted under a suspended or stretched ceiling. They are attached directly to the power cover.

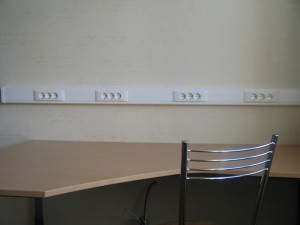

Wall box

It is used for laying power electric wires, laid from the installation wiring box to switches, sockets. To make the room aesthetic appearance with mounted cable ducts, the latter is advisable to install in the corners of the room.

Floor type

In most cases, the plinth with a built-in cable channel can be successfully replaced, especially if the wire bundle has a large cross-section. From a certain size, the box has the ability to overlap the gap between the wall and the floor covering.

The cost of the cable channel 12x12x2000 starts from 9.06 rubles.

Advantages of plastic boxes

- A sturdy box-like design that is capable of withstanding a certain mechanical impact (impact) and does not deform from the weight of the padded cables.

- The operating range is -50 ° ... + 70 ° C.

- Not combustible, fireproof.

- Easy-to-use - easy, easy installation with further operation.

- The ability to give external elements the necessary color.

Other materials used

Steel alloys

Gives the product greater strength. Can be performed with different sizes. But with the increase in size, the body's own weight, value, grows. Has a significant drawback - it is a conductive material. In damp areas, the housing can undergo corrosion and rust.

Aluminum alloys

Have sufficient rigidity. They have low weight. Are not subject to corrosion. Quite expensive. Well conduct electric current.

Polymeric material, plastic

Products from it are inexpensive. Easily mounted on flat and slightly uneven surfaces. Technologically in work - the material is processed by a hacksaw for metal or a cloth on a tree with a small tooth; is cut by a Bulgarian. Screws into the body of the box without difficulty, without preliminary boring.

Boxes made of metals require a mandatory grounding.

When choosing a cable duct, it is necessary to draw on its fireproof properties. Such information is contained in the fire certificate for the product.

In addition, the document should include the following information:

- full name and location of the applicant;

- the name and location of the firm of the manufacturer (or importer);

- information about the product: name, classification codes, brief technical description, purpose;

- reference to normative documents.

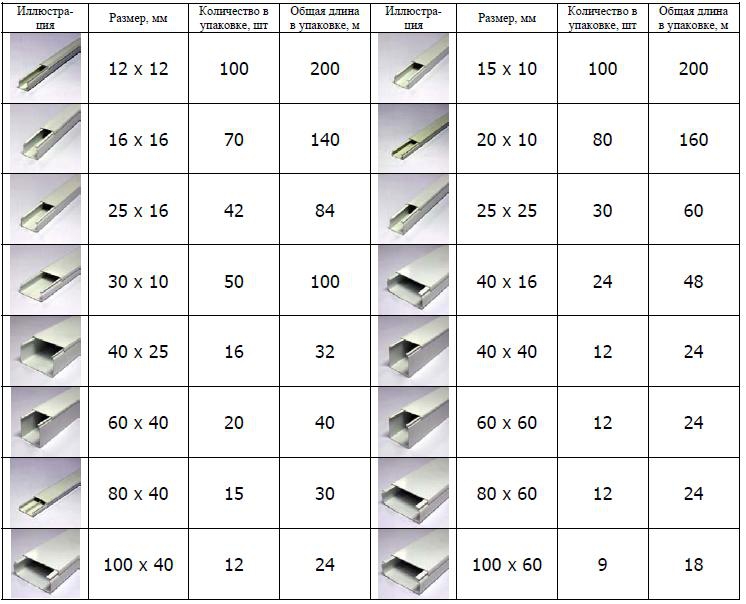

Basic dimensions of a rectangular cable duct

The most common, rectangular in the cross section of the box, is produced in length of 2 meters. The cross-sections are 12 x 12; 16 x 16; 25 x 16; 25 x 25; 40 x 25; 60 x 40; 80 x 40; 80 x 60; 100 x 60.

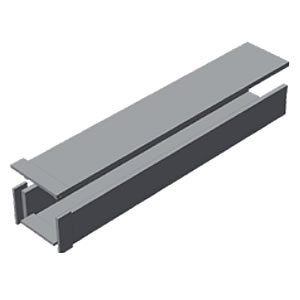

Cable channels with large cross-sectional dimensions can be made with several internal partitions. This is done for stacking in different trays of power power cables, dedicated lines for a television signal or Internet cables. For wires of burglar alarm systems, a separate channel can be allocated.

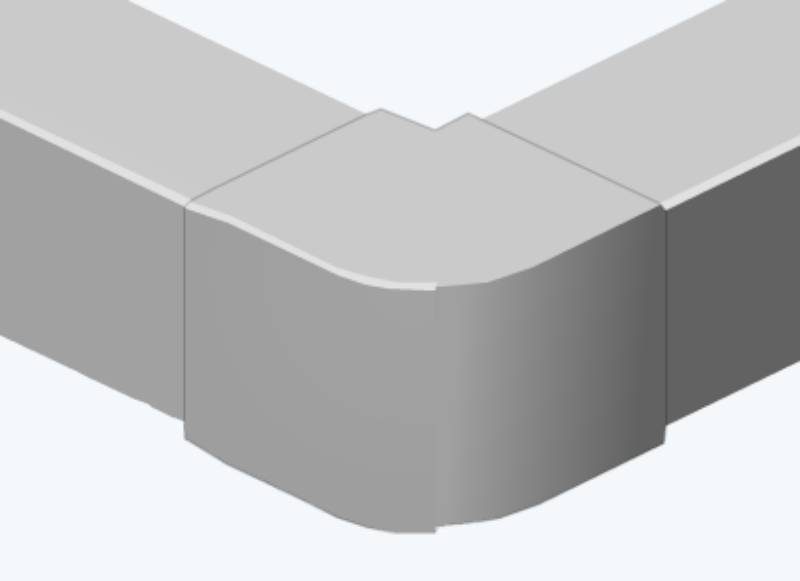

To round the inner or outer corners, turns, bends, special structural elements are produced, allowing the bending of the latter without damaging the wires. In addition, connectors of the boxes themselves are produced with each other.

The number of transitional structural elements is considered according to the technological drawing or is determined visually. The total length for similar boxes is also calculated from the drawing with the addition of approximately 10% to the pruning.

The cross-section of the box is calculated based on the number of cables to be laid. For this, the cross-section of each cable is determined separately. The result is added up and increased by about 30 ... 50%. This is due to the fact that the wires have a circular cross-section and there is always free space between them.

Installation

Required tools for installation:

- impact drill or perforator, you may need a screwdriver;

- drills, drills of the required diameter;

- phillips screwdrivers with Ph 2 or 1 tip;

- bits for screws for a screwdriver;

- a hacksaw for metal and wood, but with a small tooth;

- angle grinding machine (USM, "Bulgarian") with a thin cutting disc;

- hammer weighing 200 ... 400 grams;

- pliers or pliers;

- marking tool (dash, marker, pencil);

Since the surface is not always smooth, it is necessary to strive to ensure that the boxes have been mounted evenly, without special distortions. Otherwise, serious difficulties can occur when the covers are snapped.

It is not uncommon for administrative and residential buildings to install external wiring. This need arises when new electrical appliances are installed in the room or the wiring passage in the wall is rendered unusable.

Shtroblenie walls are not always possible or leads to protracted repair, and in industrial premises there is no need to hide the wires in the wall. A good solution for neat and safe laying of wiring over walls is a plastic box.

Benefits

Plastic cable duct, as it is called plastic box for cable, is a pretty good design made of polyvinyl chloride. So, in comparison with other devices or types of packing, plastic box has such advantages:

- aesthetic appearance;

- a variety of colors, which allows you to choose a box for the interior of the apartment;

- strength of the product, which is resistant to shock and allows you to withstand the weight of a heavy cable;

- fire safety, corresponding to the current rules;

- resistance to temperature changes;

- simplicity of installation and maintenance.

Due to such properties, plastic wire ducts are becoming increasingly popular when conducting an external wiring installation.

In addition, the most famous producers of plastic cable channels, such as "Alekor" and "Legrand", complete their products with different fittings, which helps to considerably improve and improve the design of the plastic box for wires. Elements such as end caps, tees, internal and external corners, allow you to get rid of holes in the trunk and greatly accelerate its installation. The production of cable channels from PVC is carried out using modern technologies and is constantly being improved.

Selection and calculation of material

In order to make a normal and reliable installation of the PVC box, it is necessary to determine some details and conditions of the forthcoming work.

When planning the installation of a cable duct from PVC, the following factors are taken into account:

- The thickness of the wiring and other cables that will be installed.

- Dimensions of the box for individual mounting areas.

- The possibility of installing additional wires and cables in the future.

- The material of the surface on which the cable duct will be installed.

- The possibility of using a PVC skirting board with a cable duct for the placement of wires in it, with wiring inside the rooms.

![]()

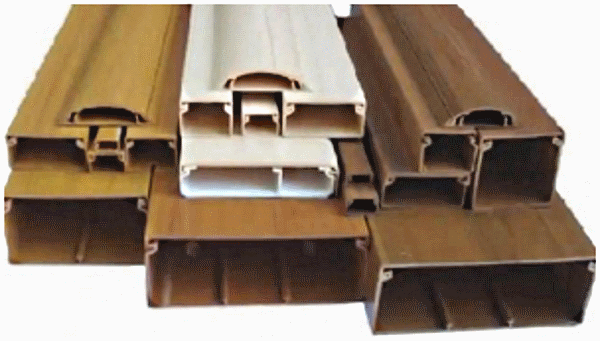

On sale there is a plastic box for wires 2 m in length and of various sizes of width and height. The shape of plastic cable boxes can be very diverse.

They can be made in the following form:

- rectangle;

- square;

- triangle;

- semicircle.

Based on the shape and size, the plastic box can be:

- Ceiling type. This product has the smallest size, since it contains thin wires designed for chandeliers or spot lights. It is used, as a rule, when laying a new line on the slab. In addition, when installing a suspended ceiling from PVC panels, the box is used to distribute electricity to the fans and lights. A good solution is to use a perforated plastic box for placing wires on the ceiling during installation stretch ceilings from PVC-film. The ability to quickly make a lateral hole in the walls of the box, when it is fixed to the surface, significantly saves power and time.

- Wall type. The wall version serves to lead the wires to the outlets and to the ceiling. For the outlets you need fairly thick wires that can withstand powerful electrical appliances. Proceeding from this, for them the appropriate size of the box is selected. The output of the wire to the ceiling is best done through the cable channel installed in the corner. There it will not be conspicuous, but with a tastefully chosen color - can harmoniously complement the interior of the room.

- Sexual type. The floor plastic cable-channel quite successfully replaces the usual wooden or plastic floor skirting. The size here is not so important as for wall and ceiling products. The large size of the genital can be regarded, rather, as a plus. In addition to closing the gap between the wall and the floor, the availability of a spare space under the cover can be useful for the subsequent laying of satellite television cables, alarms or the Internet in it.

On a note: Plastic products of white color are presented in the largest assortment. They can easily be given the right color by dyeing or pasting with a film.

Installation of a plastic cable duct

Before installing the cable, you must determine the size of the shape, quantity and color of the products that will be used during operation.

Drafting

The design consists in drawing up a layout of the wiring, television and optical cables in the room. Based on the thickness of one wire or their bundle, the type and size of the box is chosen. The diagram details all of these nuances.

- connecting plates;

- internal and external angles;

- mounting PVC boxes for wiring;

- plugs;

- tees;

- fastening material.

When the required number of different types of box is calculated, you can find out the number of fasteners. Usually, self-tapping screws and plastic dowels are used for fixing. The mainline is fixed on the surface every 30 cm. You must multiply its total footage by 3.3 to get the number of screws.

Acquisition of material

Before going to the store for shopping, it is recommended to familiarize yourself with the assortment of the product and its prices on the sites of construction stores. This will save not only money, but also time.

If you have to make purchases in several places, it is better to hire a cargo taxi. So the goods will be safe and under control. Carry PVC products in the trunk of a car is not recommended - they can break or scratch.

During the purchase, you should carefully inspect both the panels and accessories.

Attention should be paid to the following:

- No deformation. When storing parts on short racks or folded unevenly, they warp and assume an irregular geometric shape that can not be changed.

- Presence of mechanical damages. Cracks in products can lead to breakage of individual fragments during installation.

- Condition of the coating. It should not be stained, shabby or burnt in the sun. Such defects will greatly spoil the overall appearance of the structure.

The material should be purchased with strong walls. It is possible to test the reliability of the lock connection on one of the pieces of the box when viewed - its lid should be softly, with a slight effort to be removed and, easily, without striking it, close. The absence of a sharp click indicates the quality of the product.

Instruments

The very process of building a highway, after this process is designed and prepared, is a fairly simple exercise. All that's left is to prepare the instrument.

For work you will need:

- perforator;

- screwdriver;

- hacksaw for metal;

- stool;

- a hammer;

- sharp knife;

- pliers;

- pencil or marker.

The set is simple and there is in every house. Having collected it and checked up serviceability, it is possible to start work.

Installing the cable channel

Having a project, material and the right set of tools, it's easy and fun to work with.

The stages of this work are as follows:

- Carry out marking on the surface. The location of the highway is applied, marks are made for drilling.

- In the surface holes are made, plastic dowels are inserted in them.

- Screws the case of the box.

- Laying of wires and cables. They can be stacked one at a time or in combination with the use of a plastic screed.

- Wiring is carried out.

- Sockets, corners, plugs and a cover of the case are established.

The work is done.

Video about the assembly of the cable channel

If you decide in the house, the best way to hide the cable line is to purchase special plastic boxes. That you could correctly choose products on color and a design, further we will give to your attention all kinds and the sizes of a cable of channels for wiring.

Design

So, the first thing I would like to draw your attention to is the difference in the design of cable channels. Today the best producers electrotechnical products (for example, Legrand, IKE or DKS) have in their assortment the following types of plastic boxes for electrical wiring:

These are all the most popular types of cable channels that can be used in homes, administrative and production buildings. With regard to materials of manufacture, the boxes can be made of non-flammable PVC plastic, aluminum, glass and stainless steel. The latter, metallic, have a rough appearance, so in living quarters are practically not used. In more detail, see what the trays are and how to collect them, you can in the video below.

Product overview

Dimensions

With the dimensions of the cable channels, everything is much simpler. You can see the assortment of cross-sections in the table below:

It should be noted that some manufacturers may have other sizes of cable channels, for example, 80 * 45 mm. The most popular are 12 * 12 (for laying communication cables), 40 * 40 and 100 * 60 mm. At the corner trays the most practical section is 40 * 40 mm.

Color Solutions

Well, the last thing I wanted to talk about is the color of the cable channels. To date, you can order any suitable color for the interior color boxes. A very popular are cable channels under the tree, which are recommended for use when

Cable ducts, metal - products intended for the installation of wiring or any other cable, the boxes may be provided with a snap-on cover that securely holds the cable or cable system inside the box.

The cable ducts can be supplied in various colors according to the international catalog RAL, they are produced in different types and sizes and are applied taking into account possible options for their use.

Products of HEAMThe site of electrical installation products of GEM SZPKCable Metal Box TU 34-43-10-167-80. KP box It is used for laying cables and wires with voltage up to 1000V in the open air, inside buildings and structures. A box made of steel with a paint and varnish or zinc coating is produced in accordance with GOST 9.302-88. Metal Cable Box Cable box of metal type U |

|

|

Boxes of cable metal SCRCable boxes for metal cable lines for laying cable routes with voltage up to 1000V inside and outside buildings, in horizontal and vertical planes.Standard version УХЛ2,5 |

|

Fireproof cable ductsBoxes are cable-fire-resistant RMS metal with a lid, for laying cable networks and wires with voltage up to 1000V inside and outside buildings, are used in horizontal planes.Length of straight section: 2500 mm. |

|

Vertical refractory boxCable box for laying wires and cables with voltage up to 1000V in a horizontal plane inside and outside the premises. The fire resistance limit is 40 minutes. Used in explosive environments.Length of straight section: 2500 mm |

|

Cable boxes flat seismic resistant series KKPSThe KKPS boxes are designed for laying wires, control and power cables voltage up to 10 kV inside and outside buildings.Degree of protection: IP20 |

|

Cable boxes flat seismic resistant series KPSMetal cable boxes are used for laying power and control cables and wires in them with voltage up to 10 kV inside and outside buildings, as well as in cable structures of thermal power plants, nuclear power plants and production facilities.Coverage according to GOST 9.032-74 * or metallic (galvanized) according to GOST 9.302-88. |

|

Cable boxes metal block KKBThe SZPK produces seismic resistant cable boxes of the cable block type KKB-P, KKB-UNP, KKB-UVP, KKB-UGV, KKB-UGP, KKB-PO, KKB-UGN, KKB-UN, KKB-UV.Boxcable block type metal are designed for laying power cables and co-power and control cables for service areas, farms, columns and walls under the ceilings inside buildings and structures, as well as in the open air on special and technological platforms and other supporting structures. Degree of protection: IP20 Standard execution of V1 and V5. |

|

Metal casing SLLVLaying of wires and cables with voltage up to 1000V for laying cable lines in a vertical plane inside and outside the premises. Used in corrosive and corrosive environments, petrochemical plants, gas, chemical and metallurgical and food industries.Standard version: УХЛ2,5 Under the order УТ1,5 |

Advantages of cable ducts SZPK

SZPK - the leading manufacturer of electrical installation products, which has branches in the largest regions of Russia. Since 2012, we have manufactured and installed over 1 000 000 m cable trays and boxes to our customers in Russia and abroad. All products comply with GOST, strict quality control is carried out at all stages of production.Widely distributed cable boxes have been obtained due to the convenience of installing external wiring, the ability to add and remove wires and cables, a fairly low cost of installation and at the same time with cable boxes it is possible to maintain an aesthetic appearance and safety in the operation of cable systems.

Metal cable ducts have high strength. A special durability in operation and high safety is ensured by galvanized cable ducts. The use of cable boxes during the laying of cable systems creates the conditions for a simple, convenient, low-cost installation, and above all, ensure the safe operation of cable systems with the ability to change and supplement when necessary.

The hidden method of laying electrical wiring is preferable, as the fire increases - and electrical safety, and also the possibility of its damage is excluded. But often there are situations where only open method, for example, in a wooden house. The photo below shows one of the most common variants of such a padding. It uses a plastic box for wiring, with the installation of which will cope with most home masters.

Open wiring in a box

Device

In the cross section, the wiring box can be rectangular or square. It consists of two parts:

- Base. It represents most of the structure and consists of the bottom and side walls. For fixing to the wall there may be holes for fasteners. If they are not, you will have to drill yourself. The side walls are provided with projections serving as a lock for connection to the upper part.

- Top part. It also consists of a base and small lateral walls with minor depressions on the inner edges intended for connection with the base lock.

After installing the box and performing wiring installation, the upper part is pressed against the base until it locks into the lock. The figure shows boxes of different sections in the assembly.

Plastic boxes of different sections for wiring

Advantages of plastic boxes are as follows:

- low price;

- a small cost price;

- resistance to moisture, fire, corrosive environments;

- sufficient strength;

- electrical safety;

- a wide range of colors;

- the possibility of mounting outlets and switches on the top;

- ease of installation and machining.

The metal box is made of aluminum or stainless steel, resistant to external influences of the environment. To protect against corrosion, zinc or aluminum zinc coatings (zinc-aluminum alloy) are used. Products with coatings are cheaper than stainless steel. Their low electrical safety requires the installation of cables with high-quality insulation.

Classification of cable channels

Open wiring can be performed on insulators. With a competent performance, it will look attractive, but this method is not suitable for every interior. The installation in corrugated pipes is more acceptable for auxiliary rooms. With a modern approach to open wiring, the best option is a cable duct with the following advantages:

- aesthetic appearance;

- safe operation of the wiring;

- easy access to cables and wires;

- does not support burning.

The cable-channel is a U-shaped profile. It is attached to the surface, then the wiring closes with a lid on the latches. Products are produced in the form of "sticks" 2 m long.

They also produce more complex designs of boxes with internal partitions. They are supplied with one common or separate covers, and the cables are stacked in different channels.

Plastic box with internal partitions for wiring

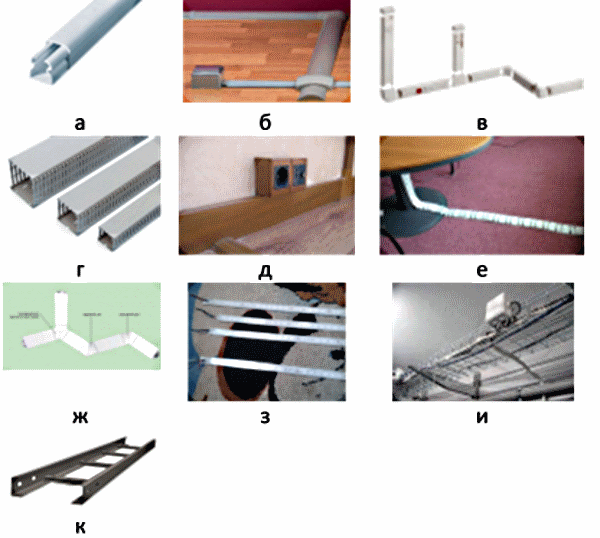

Structurally, the boxes differ in the following way:

- Mini cable channels (figure a below). Applied when laying wires to computers, telephones and TV. They are unobtrusive and do not degrade the interior of the premises.

- Floor (Figure b). Have the shape of an oval and do not interfere with movement around the room.

- Parapetnye (Fig. C). Most often used in residential buildings, office buildings, offices. They hide the wires from household appliances.

- Perforated (Fig. D). The side walls of the box are made with slots, which makes it possible to reduce the weight of the structure.

- Skirting boards (picture e). The electric skirting board is made with cable ducts. Widely distributed in residential areas, as it does not violate their design.

- Flexible (Fig. E). Perforated form allows to bend the box in accordance with the surface profile. Especially devices are needed for architectural irregularities and bends. The shape is rectangular or round. Plastic and rubber are used as materials.

- Corner ones (fig. G). The cable duct is made in the form of a ceiling skirting. It is convenient to make wiring under the ceiling, at the joints with the walls.

- Transparent (Fig. They found application for placing LED ribbons in them.

- Wire mesh (Fig. This is one of the cheapest types of cable tray used in technical rooms or warehouses. They do not settle with dust, and favorable conditions for ventilation are created.

- Staircases (Fig. They can lay a lot of cable, because the profiles can withstand significant loads.

Popular types of cable ducts for electrical wiring

Choice of cable box

The most practical in use are plastic products. They are lighter in weight and in processing. The box is easy to fit in place during installation. A special advantage is the insulating property of the material.

After calculating the required number of boxes, the ordered footage should be increased by 10-30%. If it is deficient, it will be difficult to find an additive in the future. Do not economize on the accessories that give the wiring a finished look: corners, turns, tees, etc.

![]()

Exterior of the box with accessories

The cross-section of the box is determined by the formula:

S = (N ∙ d) / K, where

- S - section of the box, mm 3;

- N - number of cables, pieces; d - cable diameter, mm;

- K = 0.45 is a coefficient that takes into account the free laying of the cable, it should not be too dense.

If the cable channel is selected smaller, the cover will not close securely, and the wiring may overheat if the packing is too tight.

Before buying, you must do the following:

- Choose installation locations and the required number of lamps, switches, sockets and other accessories.

- Draw a diagram of the open wiring in the house or apartment.

- Calculate the required footage and dimensions of the boxes in accordance with the cross sections and the number of cables.

- Choose the right tool and mounting hardware.

- Decide on the materials of the boxes. The advantages of metal products are strength and fire safety. Advantages of plastic boxes were mentioned earlier. In this case, it is necessary to take into account such a drawback as their deformation from the load by wires. In this case, the cover may not coincide with the housing and it will have to be placed on the adhesive.

Particular attention should be paid to the cable channels laid on the ceiling. Under the weight of the cable, the lid can be opened, so the connection should be chosen more durable.

Model Selection

The type of cable channel depends on the type of room. For wiring in a frame house, metal boxes are used. They are installed in false ceilings, in partitions and raised floors. The box is screwed to the base with a screwdriver and cables are laid in it, which are fastened to the channel by clips made of plastic.

In an apartment or house, open wiring is done on walls or ceiling. The box model can be selected by color. On some devices, a picture is applied using the photoprint method. It costs more, but this model looks like an element of design.

The best are products made of aluminum produced by German or Italian companies. The outer side of the cover imitates natural materials, for example, wood.

It is desirable to choose boxes with partitions to separate the trains. The lid should preferably be selected with latches on both sides (figure a below). A one-way lock keeps it worse.

Box with snaps: a - on both sides; b - on the one hand

Installation of a box under electroconducting

The box is selected for the cross-sectional area of the cable. It also requires mounting boxes for connecting the cores. Boxes are classified by size in mm:

- micro-channels - 13x7 - 16x13;

- mini-channels - 33x10 - 40x16;

- the usual sizes are 100х40 - 300х80.

The surface of the substrate should be smooth and finished. To the plasterboard the box is attached with small self-tapping screws. For not very even walls the ducts are installed with a sag, without stretching.

In the walls are made holes in which dowels are inserted to fix the bases. Superfluous parts are cut off with a hacksaw for metal. Then the cables are laid and covered with a lid. Hard cables are harder to pack. They are aligned as they are laid. Here the boxes with longitudinal partitions are better.

From the openings the track should be laid at a distance of at least 100 mm, and from the ceiling - 150 mm.

Do not forget about the installation on the line junction boxes, facilitating the repair of wiring.

Video about wiring

How the wiring in the cable channel is arranged in a wooden house is described in the video below.

When installing an open wiring in the boxes there are many nuances. The main thing here is the fulfillment of security requirements. The owner of the apartment must know the methods of choosing boxes and the rules for their installation in order to do the installation yourself or to check the quality of the gasket for electricians.