Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

The problematic area of life support for a private house is the water supply system, since there are many difficulties in terms of water supply, for example, in winter. The main obstacle here is the fact that pipes can simply freeze in winter. Although they can be located below the freezing point of the ground, but it does not completely avoid problems, since the place of entry of the water pipe into the house is in any case critical. However, this problem is relatively easy to solve if you use the device in the form of a self-regulating cable, which makes it possible to provide constant water supply without any interruptions associated with low ambient temperatures.

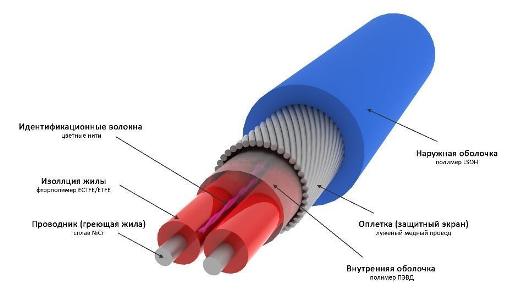

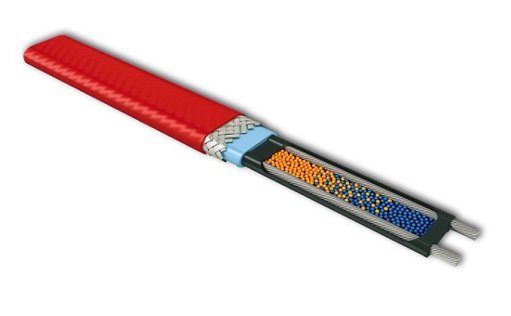

Before you learn how to make heating, we learn more about the cable itself for heating gutters. The considered type is an electric belt heater, the construction of which provides the presence of parallel conductors separated by a polymer matrix. This semiconductor matrix is capable of releasing heat due to the fact that in its middle there is a heating cable for the water pipe, which contributes to the continuity of heating. Features of this product are as follows:

Principle of operation

Heating cables of the type under consideration, that is, focused on automatic regulation of the heat produced, have in their composition a polymer matrix, which is an element of resistance capable of differently opposing the current depending on the degree of its heating. The actual heating of the matrix is due to the fact that it is in contact with two conductors that give off heat due to the current flowing through them. When the matrix is heated, its resistance increases, and the current decreases.

In this connection, it is possible to achieve a certain balance between the power consumption of the self-regulating cable and its temperature. For example, a lower ambient temperature leads to more power release, which is also natural in the reverse order. The cable for heating the water pipe can be in an environment that differs in its characteristics in different sections, so the temperature of the cable will not be the same either.

As a result, it is possible to achieve the effect of self-regulation, when the energy released by one wire is not uniform over its entire length. If certain areas are in a cold environment, then more energy is released, and if in warm, then less. This same effect avoids overheating of certain sections of the cable, which is provided by their different responses to changes in the temperature background.

The current is closed in a self-regulating cable by means of a matrix in parallel. This provides the possibility of connecting a voltage of 220 V (working) to the cable without limiting its length. Although this is more theory, since there are restrictions, but they are more closely related to the current load and inrush current parameters, which have acceptable values for copper busbars. Failure to comply with these parameters can lead to the destruction of contacts that serve to connect copper busbars and polymer matrix. The values of the starting current of the system exceed the nominal current by two or three times. The possible length of the sections is 60 to 100 m, depending on the type of cable used.

Positive moments of self-regulating cables

Classes of cable depending on temperature

Thermocables are divided into three classes:

- Low-temperature - suitable as a protection of pipe pipes from freezing, as well as in cases where it is necessary to produce thawing of a pipeline of small diameter. The maximum heating parameter is 65 ° C, and the specific power is 15 W / m.

- Medium temperature - provide heating of drainpipes, thawing of the roof and frozen pipes having an average diameter. Heating up to 120 ° C with a power of 10 to 33 W / m is guaranteed.

- High-temperature - cables of this kind are used in industry, so they are able to heat up to 190 ° C at a power of 15 to 95 W / m.

With braiding or without: which is better?

Thermocables are available with or without braiding, which determines the different characteristics of the final product. A cable that does not have a braid is the cable itself and only one layer of insulation that is external. The absence of a braid significantly reduces the cost of this product.

In the case of a thermal cable supplemented by a braid, which consists of copper wire, everything changes radically - the product acquires new properties. In particular, it becomes stronger and more reliable, and the braid also provides grounding. At the same time, its cost significantly increases.

What capacity is required?

To buy a high-capacity thermal cable without justifying this purchase in terms of its relevance is an unreasonable waste of money. The equipment must meet the needs. If the power of the product remains unclaimed, then the empty electricity consumption will increase.

To buy a high-capacity thermal cable without justifying this purchase in terms of its relevance is an unreasonable waste of money. The equipment must meet the needs. If the power of the product remains unclaimed, then the empty electricity consumption will increase.

The power must be selected taking into account the diameter of the pipe. The larger diameter is the greater the power of the wire. This ratio is not ideal, since there are additional parameters that affect such calculations. For example, the presence and thickness of the thermal insulation layer on the pipe provides a reduction in heat loss, so the cable under these conditions can be selected and less powerful. With respect to a specific range of pipe diameters, we determine the required power in each individual case:

- from 15 to 25 mm - 10 W / m;

- from 25 to 40 mm - 16 W / m;

- from 40 to 60 mm - 24 W / m;

- from 60 to 80 mm and for 110 mm pipes of sewage systems - 30 W / m;

- from 80 mm to 40 W / m.

The information given is enough to correctly determine the purchase of a self-regulating cable, which will save money.

Thermal Cabling

Self-regulating cable can be installed inside the pipeline or outside. At low temperatures, installation can not be performed, as it is possible to damage the protective layer of the polymer. The minimum permissible temperature for the installation of the thermal cable is -5 ° C. In the case where the flexibility of the wire decreases due to the temperature conditions of the environment, it is gently unwound and briefly connected to the mains, which will restore the physical properties of this product. Only then you should proceed to install it.

Internal mounting

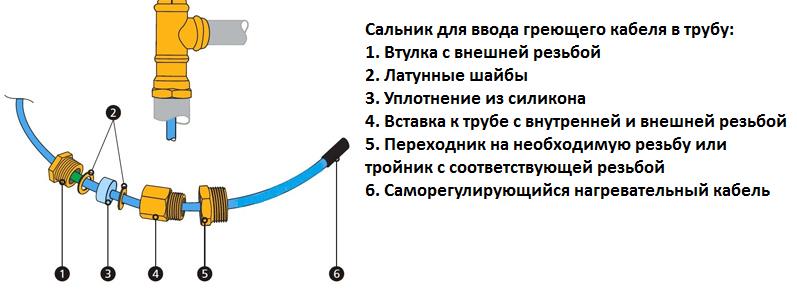

The internal installation method applies to pipelines having a diameter of up to 50 mm, with limited access. In situations of this kind, the thermal cable is laid over the entire length of the pipeline. The input is carried out by means of a stuffing box consisting of two bushings and the same number of washers, including rubber seals.

If an internal heating device is planned for the pipelines ensuring the delivery of drinking water, it is necessary to use a self-regulating cable, which is supplemented by an outer shell based on a polymer containing fluorine. Such a thermal cable must also undergo the necessary tests for compliance with sanitary and hygienic standards.

If an internal heating device is planned for the pipelines ensuring the delivery of drinking water, it is necessary to use a self-regulating cable, which is supplemented by an outer shell based on a polymer containing fluorine. Such a thermal cable must also undergo the necessary tests for compliance with sanitary and hygienic standards.

There are the following rules for the use of a heating cable, capable of regulating the temperature of heating in different areas of its surface:

- must have the same length as the length of the pipeline;

- the cable for indoor installation can not be used in shut-off valves;

- it is necessary that the pipe has a mark about the fact that it has a drainage system installed;

- the process of inputting the wire must be carried out with extreme caution in order to maintain the integrity of the outer shell;

- before laying the cable, you should take care of the fittings - their edges require closing by means of the factory tape to avoid damaging the thermal cable.

External mounting

Placement of the heating cable over the pipe is characterized by a rather wide variability of methods:

- linear - installed on small diameter pipelines in the form of a line running along the pipe;

- parallel - installation is carried out on large diameter pipelines or on water supply systems that are located in the open air; in this case, mount two or three cables running parallel to each other on the pipes;

- spiral - the cable, as it were, wraps the pipe along the line of the spiral with the pitch of the turn, depending on the parameters of power and diameter of the pipeline;

- wavy - is used as a replacement for the previous version, due to the fact that the length of the cable is simply not enough; laying a wire for heating pipes with a wavy line suggests a lower consumption of the starting material.

Due to the self-regulation function, the heating cable can be overlapped, which is used when it is necessary to heat the shut-off valves located outdoors. External laying should be correlated with requirements, the observance of which would exclude the possibility of wire abrasion and other negative mechanical effects. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off valves, for example in the form of valves.

Due to the self-regulation function, the heating cable can be overlapped, which is used when it is necessary to heat the shut-off valves located outdoors. External laying should be correlated with requirements, the observance of which would exclude the possibility of wire abrasion and other negative mechanical effects. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off valves, for example in the form of valves.

The thermal cable should be relatively rigidly attached to the pipeline by using aluminum tape. Upon completion of installation, the pipeline is necessarily insulated to reduce heat losses. Connect the water supply cable to the 220-240 V network only through the RCD, as described in the corresponding instruction.

What are the advantages of a cable with a thermoregulator?

Heating of the water supply system assumes a significant flow of money, since the heating elements consume electricity. To reduce these costs, you should use cables equipped with thermostats. These devices are good in that they include a heating system when the temperature drops to +3 ° C, and turn it off when reaching the mark of +13 ° C.

For example, water coming from a well is unlikely to be higher than +13 ° C. As a result, the heating of pipes in this case will be carried out all year round, and this is inefficient. At the same time it is asked whether it makes sense to heat the water entering the drain tank. It is much easier to set the switch-off temperature +5 ° C and lower the costs going to the heating of the gutters.

For example, water coming from a well is unlikely to be higher than +13 ° C. As a result, the heating of pipes in this case will be carried out all year round, and this is inefficient. At the same time it is asked whether it makes sense to heat the water entering the drain tank. It is much easier to set the switch-off temperature +5 ° C and lower the costs going to the heating of the gutters.

As a result, there will also be a positive effect such as an increase in the life of the heating cables. The operation of each thermal cable occurs with the development of a resource that determines how long the product can work without losing its properties. Therefore, a shorter working time increases the life of the self-regulating cable.

Installation of heating systems equipped with temperature controllers must be related to the installation of a temperature sensor, which is determined by some complexity. The sensor must be mounted so that the heat of the heaters does not have any influence on it. It is necessary to use thermal insulation, which would serve as a barrier between the sensor and the thermal cable.

Installation of the thermostat should be done indoors. For its connection, a house electric board with an intermediate device in the form of an RCD is used. The heating cable consumes little power, therefore the suitable rating of the machine will be 6A, and the nominal value of the RCD is 30 mA. The heating cable is connected by means of special connectors on the housing.

The Russian climate is very severe, and in winter, the water and heat supply systems are subject to sharp temperature changes, which can result in the freezing of the pipeline or, worse, the interruption of water and heat supply to homes. Therefore, water supply systems need high-quality insulation or heating.

Not always the insulation of the pipes guarantees their performance during long frosts, but the self-regulating heating cable for the water supply will be a full protection of the pipeline in any weather, no matter how low the column of the thermometer falls.

The water pipe is wrapped with a heating cable in the winter season

These conventional wires, designed to heat pipes, have their own insulation design, which differs depending on the kind of heating cable. It should be noted that in modern conditions, such wires are used not only for heating pipelines in winter, but also for heating drainage systems to melt ice and snow gathering in gutters. This saves them from destruction.

The industry produces two types of heating cable:

- Self-regulating.

- Resistive.

- A product with mineral insulation.

Despite their almost identical function, they differ in their design and heat dissipation scheme, which implies a special attitude to them during installation.

|

|

In turn, a resistive heating cable for water supply may be:

- Zone or linear.

- Single- or double-core.

Resistive cable for water supply

Resistive cable consists of one or more metal strands, which are covered with multi-layer insulation:

- Heat-resistant PVC plastic in the first and last layer.

- Fluoroplastic.

- Shielding braid of copper.

The circuit of the resistive cable

This cable heats the entire length of the same, has a constant resistance. This is its drawback, as it can overheat and therefore fail. To prevent this from happening, when installing a heating cable for water supply it is necessary to install temperature sensors. Such products are characterized by a lower cost than self-regulating cables.

It should be borne in mind that in any case it is impossible to cut the resistive heating cable arbitrarily, that is, anywhere. It can be cut only by certain areas, which can have a length of 20 cm or more.

The advantages of a resistive cable include:

- Simple design.

- Simplicity of the manufacturing process.

- Low price.

- High heat dissipation and retention of inherent characteristics throughout the entire operation period.

Among the shortcomings especially noted the possibility of overheating where there is a risk of overlap or large accumulation of debris. In addition, inconvenience is also the fact that it is impossible to cut to the required size, but only by what the manufacturer offers. In case of overheating, the whole section is dismantled, while the self-regulating cable can be replaced by any sections.

The design of the self-regulating cable somewhat resembles a resistive product. And in that and in another basis are current-conducting veins. However, in the first case there is no insulating coating, and the release of heat from the passage of current through the veins can vary along the entire length of the cable.

Self-adjusting cable assembly

When the ambient temperature rises, the resistance of the polymer part increases simultaneously, resulting in a decrease in heat release. When the external temperature is lowered, the reverse process occurs. Therefore, a heating cable for a water pipe of this kind is called self-regulating. This property completely eliminates the risk of overheating or burnout of wires.

The advantages of this type of heating cable with confidence include:

- Ability to cut to the desired length.

- Saving in the expenditure of electricity.

- Increased maximum power.

- High resistance to moisture, chemical reagents, fire and ultraviolet.

However, against the background of such positive characteristics can not be said about some of the drawbacks inherent in this type of heating cable.

Heat the room quickly will not work if the cable is used for the warm floor. In addition, if the ambient temperature is low, when the heating system is switched on, there is a sharp increase in the power of the current consumed, and this, for safety reasons, requires the installation of special protective devices.

How to choose a heating cable?

Better if a choice, as well as installation, will be a professional. But the general recommendations will not be superfluous for a simple consumer. If there is a need to buy a heating cable, first of all, it is necessary to repel the diameter of the heated pipeline and its length, the place of its passage, and also the functionality of the engineering communication, since the heating cable for the water pipe inside the pipe is mounted if the diameter is small. In this case, a resistive cable is used.

Basically, the cable is selected by power. For installation inside the pipe, the resistive cable can be selected with a power of 10 kW / m.

The heating cable for the water pipe outside the pipe should have a higher power, approximately 17-20 kW / m.

Highlights of outdoor installation

Over the pipe, the cable can be laid in straight parallel rows or wrapped like a spiral.

Parallel heating cable stacking

First of all, it is necessary to check the integrity of the insulation, which should not be disturbed during operation - deformed, rubbed, subjected to great compression or stretching. At the top, the pipeline is wrapped with foil or pieces of metallic scotch are placed under the cable.

Then the laid cable is fastened with a net, adhesive tape or special clamps so that the distance between the cable and the water pipe is minimal, only for the thickness of the adhesive tape. Then the cable along the entire length is covered again with a metal adhesive tape.

This allows:

- Increase the heat transfer area.

- Reinforce the cable to the pipe.

- Eliminate any contact with the thermal insulation of the pipeline, which must be done in order to save electricity.

It must be remembered that the heating cable must be bent at a radius of at least 25-30 mm and, moreover, only along its flat side, and it is strictly forbidden to replace the foil with adhesive tape with a plastic tape.

If the pipeline is made of plastic pipes, it is recommended that they be first glued with the same metallic tape or wrapped in foil.

After that, a sleeve is attached to the pipe, connecting the heating cable to the wire equipped with a plug, and a thermoregulating sensor is installed.

Before connecting the heating cable for water supply, it is necessary to prepare its ends. All of them are separated and peeled to a distance of about 1 cm. Each cable wire is closed with a tube of heat shrinkable material. All connections must be carefully isolated. After that, the supply wire and the heating wire are connected together.

After the end of the installation work, check the resistance value of the resistive or self-regulating cable and the quality of the insulation.

Mounting the cable inside the pipe

When installing the cable in a drinking-water pipeline, use wires that have a food suitability certificate. In this case, the upper insulation must be made of a polymer containing fluorine. For installation, an oil seal or special sealed coupling is required. When the cable is laid from above, it can not be fixed rigidly.

Internal installation diagram

But the lower connection will require a secure attachment to prevent the heating cable from slipping. It is not allowed to pass the cable through the stop valves, and the sharp edges of the threads of the fittings should be better covered with a special tape from the factory.

How much does the heating cable for the water pipe cost?

Today it is not difficult to buy a heating cable. It is offered both by building supermarkets and by online stores. The price of a heating cable for a water pipe depends on the country of the manufacturer, its technical characteristics and much more.

At present, the variety of heating cable is amazing. It is produced both abroad and in the territory of our country. The approximate cost of one running meter of heating cable is shown in the table below.

| Make | NelsonLimitrace | Devi-iceguard | Lavita HWS 30-CR | E& S Tec. Co. | ThermopadsFPC SR |

| Power, (W / m.) | 16 | 18 | 30 | 16 | 10 |

| Price per square meter, (rub.) | 470 | 712 | 283 | 918 | 230 |

| Max Length (m) | 139 | 800 | 300 | 150 | 100 |

| Service life (years) | 20 | 20 | 20 | 20 | — |

It's just, probably, a thousandth of everything that is offered to the consumer today. Therefore, the choice of such products must be very carefully and better instructed by a specialist.

In conditions of frosty winters, usual heat insulation is indispensable, so it is worthwhile to resort to an additional option, which is the heating cable inside the pipe. If you use such a cable, you can maintain the required temperature, and protect the pipes from condensation. In this article, let's look at the types of heating cables and the features of the choice.

About heating cables

Advantages of the cable system

The cable for heating pipes inside is a tool that has been used for quite a long time. In fact, this is a normal cable, which can be adjusted electrical resistance, while also regulating and actually heating the cable.

It is recommended to use the heating cable inside the pipe, it is important at minus temperatures to prevent freezing of water in the areas that run outside the house. Turn on the cable at a temperature of 5 ° C, so the system will continue to protect from freezing as it freezes.

At a negative temperature, the system should not be turned on, since in this case it will take time until the frozen liquid is thawed. And all this time will be significantly reduced the pressure in the water supply.

Advantages of the cable heating system:

- Under the condition of correctly performed calculations and installation of the heating system, it is possible to prevent the pipes from freezing during the entire operational period.

- The system is quite safe, it can be used in pipelines with drinking water, allowing to prevent their overheating.

- The versatility of the system lies in the fact that the heating cable can be used for pipes located underground, inside a building or outdoors. A cable laying can be done inside the pipe or on its surface.

- Ease and convenience of operation. Such a cable is simply fixed to the pipe, then it remains only to plug the plug into the socket, and the system will start its work.

- The economy is provided by the ability to independently adjust the power as a function of temperature.

Installation of heating cables

The composition of the internal heating cable includes several elements connected in one system:

- Plug.

- The conductor is cold electric.

- The conductor is hot.

- Thermal Limiter.

With the help of laser adhesion, the conductors are connected together. Perfect protection against moisture penetration, high temperature and chemical influences provides seamless external insulation of the heating cable.

The functions that the thermal limiter performs are as follows:

- It controls the temperature of the pipe.

- Automatic start of the system depending on the temperature. If the temperature exceeds 15 ° C, the power is turned off, and if the temperature has dropped to 5 ° C, the power is turned on, which prevents overheating of the water pipe surface and contributes to maximum energy savings.

Types of heating cable

Heating cables are divided into self-regulating and resistive, depending on which heat dissipation scheme we are dealing with.

Let's consider features of each kind:

- Resistive heating cables:

- They are subdivided into zonal and linear. When the current passes through the heating cores, linear models produce heat.

- They can be single-core or double-core, that is, have several strands of spiral or linear form.

- It should be noted that it is forbidden to cut resistive cables to obtain the required length.

- Self-regulating heating cables:

- The design is similar to the resistive, the difference is in the absence of an insulating coating.

- Heat dissipation in different parts of the cable can change, as the temperature increases, the resistance of the polymer increases, reducing heat release. This is the effect of self-regulation, which eliminates the possibility of overheating or overheating of the system.

- This type of cable, in contrast to the resistive, can be cut into parts ranging in length from 20 cm to several meters.

How to choose a heating cable

The heating cable for pipes is selected depending on the tasks that are planned to be performed by a particular heating system.

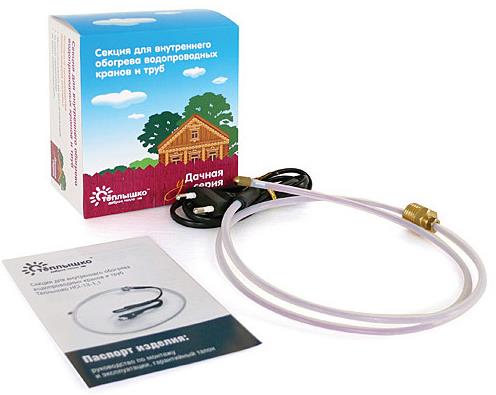

For example, for household purposes, for private houses, cottages, countryside areas, as well as for sewage systems, water pipes and gutters - to protect pipes in them from freezing, small-sized heating systems are used.

Such a cable usually has a power of about 50-60 W / m, buying a product with a higher index is a waste of money. The price for such a product is quite acceptable, and this power is sufficient to melt ice and snow, and choosing a cable with the specified power value is a reliable and economical solution.

Cables with more power require, respectively, greater electricity costs, which leads to an increase in the total cost of operating the heating cable.

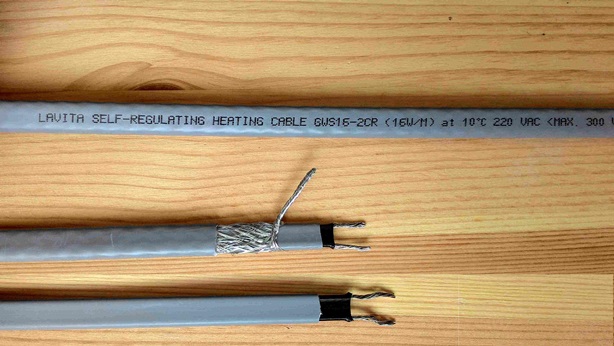

Pay special attention to the fact that today the most common self-regulating cables with two main parameters: working power and power at rest. The values of these indicators should be indicated on the surface of the product.

How to install a heating cable inside a pipe

Heating pipes from the inside with a cable is only possible if the diameter of the pipes is not less than 20 mm.

Let's list the basic nuances at installation of heating cables in pipes:

- Installation of the heating cable inside the pipe is as follows:

- in the place of insertion into the pipe of the heating cable, a saddle or a tee is installed;

- the tube insert is screwed into the saddle;

- the heating cable is inserted into the sidebar.

- The length of the heating cable should be equal to the length of the pipe section, which is planned to be heated. It is important to make all measurements as accurately as possible.

- Route the heating cable inside the pipe through the shut-off valves is not permissible.

- It is forbidden to fix the supply cable and the coupling by means of the penetration from the kit and the stuffing box when the cable is inserted into the pipe.

- All works require utmost care and accuracy to prevent damage to the cable sheath. Sharp elements, for example, the threads of fittings, should be closed for the time of installation by the factory tape.

It is necessary to place a warning label in the place where the heating cable was installed inside the pipe.

If the wire is selected correctly and the work is done taking into account all recommendations, you will not be disturbed by such problems as freezing of the water pipe and lowering the pressure in winter.

A widely used heating cable for pipes prevents freezing of the liquid flowing inside the pipeline. The unpleasant consequences of the occurrence of ice "congestion" leading to irreversible pipe ruptures can be avoided if such heating systems are installed inside or outside of them.

What is the heating cable for pipes?

The heating cable for heating pipes is heated by the action of a passing electrical current and is the main component part of the system designed to prevent the pipes of external communication systems from being defrosted.

The work of the cable is based on the conversion of electrical energy into thermal energy. A characteristic feature of these products is that they do not transfer energy, but only accept it, converting electricity into heat without using an oxidizer or fuel.

The main characteristic of the heating cable is the specific heat dissipation, measured in W / m, - shows the power that is allocated per unit of its length.

The sections of the heating cable are of different lengths. It can be a few centimeters, or rather long - a few hundred meters. Everything depends on the needs of consumers.

Heating cable construction

The components of the heating cable:

- The inner core is the main element. It is made of an alloy with good electrical resistance.

- The protective shell of the main core is a polymeric insulating material, provided with a continuous screen of aluminum or a shielding copper wire net.

- A common shell of PVC, designed to provide reliable protection of all components of the cable from the environment.

Various types of heating cables are on the market. Their price depends on the number of internal veins. The cheapest ones - single-core cables - have the simplest design. The disadvantage is that they do not have protection from electromagnetic radiation, which is provided in two- and three-core cables with an additional conductor core.

Main types of heating cable for pipes

Resistive heating cable

The principle of operation of a resistive heating cable consisting of an insulated metallic conductor:

Do not forget to monitor the temperature to prevent the heating system from burning out.

- A heating cable is laid inside or on the surface of the pipe.

- Temperature sensors are installed on the pipe.

- If the temperature falls below a preset level, the heating automatically turns on: the current heats the conductors, which in turn transmit heat to the pipes.

- After reaching the desired temperature, the system turns off

The maximum effective operation of the heating cable and uniform heat distribution is ensured with the additional presence of good pipe insulation.

Self-regulating heating cable

Pipes with heating cable - IZOPEKS, as well as other types of modern pipes for outdoor communications - are equipped with a self-regulating system, which was created as an alternative to resistive.

Self-regulating heating cable is several conductors enclosed in a polymer sheath that react very sensitively to the slightest temperature fluctuations due to a change in resistance. Lowering the temperature, reducing the resistance, leads to an automatic increase in current production, which causes the system to heat up.

Such a system reacts to minimal thermal changes in any part of the pipeline, i.e., and the heating in different parts of the cable can be completely different, depending on the situation. This property of the cable makes it possible to use it with maximum energy efficiency.

Some features that characterize the heating cable self-regulating for pipes:

- Economical.

- Reliable insulation.

- Safety of application.

- Long service life - up to 40 years.

- The possibility of dividing the cable when mounted on small parts, convenient for use.

Installing the heating cable on the pipe

Qualitatively conducted installation of the heating cable can ensure a long-term trouble-free operation of the water supply, sewage and other similar systems:

- Preparation for installation. Cleaning pipes from rust and dirt.

- Installation by own hands of a heating cable on one of variants:

- Installation of one or more parallel threads of the heating cable directly to the pipe. The number of threads is selected depending on the creation of the required power.

- Cable installation in a spiral. A more expensive option, used when using pipes of small diameter and in the case of a sufficiently long heating cable.

- Fastening the heating cable to the bottom of the pipe, which requires heating, with a special tape.

Advice! Try to fix the cable so that it is as far as possible from the bottom of the flanges or other connecting elements that can pass water. This will not allow liquid to enter the operating elements of the heating system in the event of depressurization of the connection.

- Installation of thermal insulation. It is necessary to ensure that the "cold" end of the heating cable remains outside the insulation layer.

- Power supply from the electrical panel (sockets) to the heating cable. In the case where the heating cable is mounted on the pipes in a place remote from the electrical board, you should use a junction box.

Additional compliance with certain conditions will allow a qualitative installation of the heater and get the greatest effect of heating the communications:

- Since the plastic pipes are devoid of an aluminum layer, they should be wrapped with foil tape beforehand. After that, the entire surface of the pipe will be heated evenly.

- The lengths of the heating cable, not exceeding 1.4 m in length, should be mounted to the pipeline valves, the mounting flanges. This will make it possible, if necessary, to easily disconnect the pipe system.

- Do not cross the resistive heating cable to prevent it from burning out. This does not apply to a self-regulating heating cable, since it is non-combustible.

- It is necessary to ensure the maximum possible protection of the heating system from moisture, using for this purpose heat and waterproofing.

It is necessary to provide a marking on the insulation of the pipeline with the necessary information on the presence of a heating cable on the pipes.

If the water pipe freezes, wait for trouble. The icicles that form in the pipes can sometimes reach a length of several meters. To remove such traffic jams, you need to make a lot of effort. If the winters in your region are severe, this problem must be solved in advance. At a low temperature and prolonged freezing, the usual thermal insulation does not help, so you need to look for an additional option. The most effective way in this case is to use a self-regulating heating cable for a water pipe capable of maintaining the desired temperature. It will provide good heating, as well as prevent condensation.

For the heating of sewerage and water supply systems, special wires have long been used. What is a heating cable? This is a normal cable, the heating of which is regulated by direct adjustment of the electrical resistance.

Heating cable for water supply is used to ensure that at minus temperature water does not freeze on sections of pipes running along the street. The wire is usually turned on when the temperature of the air on the street drops to 5 ° C, so that with further cooling it protects the water pipe from freezing. And if you turn on the heating, when the temperature is already below zero, it will take some time for the liquid to freeze to melt. Meanwhile, the water will gradually melt, the pressure in the water pipe will be low.

Device

The cable for heating pipes consists of cold (electric), hot (heating) conductors, a thermal limiter and a plug. The conductors are connected to each other by laser adhesion.

Since the external insulation of the heating cable is seamless, it is absolutely protected from moisture penetration, from chemical and high-temperature exposure. The temperature limiter controls the temperature of the pipe and switches off the power, with the temperature rising to 15 ° C. When cooling to 5 ° C, the power turns on again. So the electricity is saved to the maximum.

Good to know! Previously, the heating cable was used only for heating industrial pipelines, now the cable heating systems have been widely used in the household.

Advantages of using a heating cable for water supply:

- Reliability. Correctly carried out calculation and competent installation of the heating system will prevent the water pipe from freezing during its entire use.

- Versatility. Self-regulating heating cable can be connected to a pipeline located on the street or underground. The wire can be laid both on the surface of the water pipe, and inside it.

- Security. Heating cable is also used for heating the water pipe with drinking water.

- Economical. The heating capacity is controlled independently, depending on the ambient temperature.

- Ease of operation. Operates very simply: the cable is fixed to the water supply network and then plugged into the outlet.

Kinds

The nomenclature of heating wires for a waterpipe is sufficiently developed. According to the heat dissipation scheme, they are divided into resistive, self-regulating and mineral insulated wires.

Resistive heating cables are zone and linear. In linear wires, heat is released as a result of the passage of current through the heating core. The cable can be single- or double-core or has several cores of a linear or helical shape. To cut arbitrarily such a cable is unacceptable.

By its design, the self-regulating heating cable is similar to the resistive one. It also consists of two conductors, but without an insulation coating. The heat release along the length of the cable can vary: when the ambient temperature rises, the resistance of the polymer increases, and the heat release decreases. The effect of self-regulation excludes overheating and overheating of the product. Self-regulating heating cable can be cut into sections of length from 20 cm to several meters.

How to install

Warming the water pipe is a difficult task, but not urgent. For this purpose, a heating cable is used. The cable heating temperature can be varied by varying the resistance value of the device. The heating cable can be installed both inside the pipe and outside. In any case, it is selected in such a way that the heat losses of the water supply network do not exceed the amount of heat released by the system.

The cable can be laid in parallel rows or a spiral. Fastening is provided by a tightening metal mesh or adhesive tape. For better heat preservation, the tube with the heating cable is wrapped around the outside with foil. With the task of installing a heating cable, it is best, of course, to cope with the experts.

Selection

The heating wire is selected in accordance with the tasks that the heating system solves. For example, heating cables can be used both for use in private houses, cottages and countryside areas, and in public heating systems - to protect water pipes, drains and sewage systems from freezing. In this case, a small system is needed.

For these purposes, as a rule, a heating cable with a capacity of 50-60 W / m is suitable. This will be enough to melt the snow and ice. The higher power in this case is irrational.

This is useful to know! The popular self-regulating heating cable today has two main indicators - power at rest and operating power. They are indicated on the surface of the cable.

In conclusion, I would like to emphasize once again the importance of installing a heating cable in water supply, sewerage and drainage systems. Correctly picking up the wire, you can prevent the water from freezing, and avoid low water pressure.