Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

In some situations, it may be necessary to lay a heating cable for the water pipe inside the pipe. In those regions where the temperature reaches very low levels in winter, people justifiably ask the question: "Because ordinary insulation in such regions is not always effectively protected from freezing."

To avoid this, the main is equipped with heating from the inside. These actions allow maintaining the desired temperature regime of the pipeline at a significant temperature drop.

What is a heating cable

Such heating is very common in many regions of Russia. The heating self-regulating cable for a water pipe, installed inside the pipe, is inherently an electric cable, where the resistance is regulated by the temperature norm.

In a self-regulating and resistive electric cable one of the possibilities of a metal conductor is used, which, by passing an electric current through itself, heats up.

Accordingly, the higher the resistance level, the more the device warms up. It is clear that, because he is in the water.

Include self-regulating heating wire at a temperature of +5 degrees inside the water pipe. When the ambient temperature decreases, the resistance on the self-regulating and resistive wire increases, so that the water temperature is maintained at the desired water temperature.

Buy this wire can be of various lengths. It can be from two to twenty meters. They allow to warm up a part of a waterpipe by a wire, or all system if it is located in a zone of freezing.

Watch the video

At first glance, such a wire seems to be a very simple device that can be installed by oneself, and to effect an effective heating of the water pipe. But, in order to properly select and mount a heating cable inside the pipe, you need to carefully study all the information that will be set out below.

Device of heating electric wires

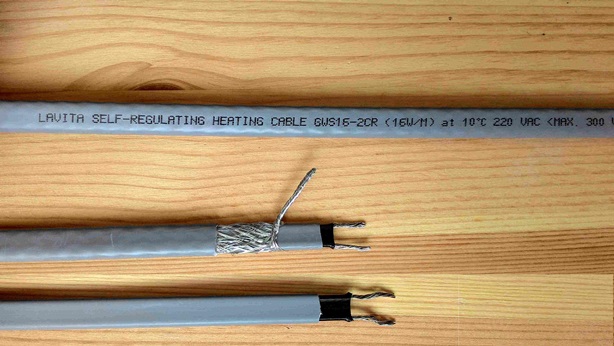

The heating cable for pulling inside the network is produced in the form of a belt electric heater. In the section of the heating device you can see the following components:

- Conductor of metal for heating.

- The veins of the heating cable are covered with heat-resistant PVC (polyvinyl chloride) insulation.

- The inner layer of insulation is covered with PTFE protection.

- All the conductors are enclosed in a screen in the form of a grid of copper.

- The last outer layer of insulation on the heating device is also made of a heat-resistant PVC coating.

The outer layer of insulation on the heating cable has the following characteristics. It is stable not only to the influence of moisture and heat, it is absolutely not afraid of the impact of an aggressive chemical environment.

Also, the cable for broaching inside the water pipe is made of materials whose composition is allowed in food production. Therefore, it can be put in a system with drinking water.

In addition, the heating cable is equipped with a temperature regulator. This allows you to monitor the temperature inside the water pipe. If the temperature exceeds the preset parameters, the system turns off the machine. These features of the device can prevent overheating and economical use of electricity.

The heating cable for installation inside the system is distinguished by the following advantages:

- Reliable operation of the heating device.

- High security.

- The possibility of using a heating wire both inside and outside the system.

- Simple installation and simple operation.

- The possibility of saving electricity through a regulator - automatic.

Perhaps the only drawback of these heating systems is their dependence on electricity. For these reasons, installation of additional power supplies is recommended on the main pipeline routes.

Types of heating wires

The heating of the mains inside, depending on the method of heat generation, is performed by devices of the following types:

- Resistive.

- These wires for warming up are: zonal and linear. Linear heat generates when passing through the electrical conductors. Such warm-up appliances consist of one or more metal strands. They on the resistive mechanism for warming up can have the form of a spiral.

- A self-heating heating cable for laying inside a water pipe is reminiscent of the previous type of devices in accordance with the operating principle.

This self-heating wire can be installed not only inside the network, but on its surface part. This electric cable can, with increasing the temperature norm, independently reduce the level of heat supply.

For these reasons, it is excellent for installation on small sections of the highway. It is not necessary to set the thermostat. Self-heating systems of cable type, are not only with a thermostat, but also various elements for installation and special glands - adapters for broaching inside the water pipe.

Self-heating heating cable of this kind has become more widely used in all systems: HDPE, metal, metal-plastic, etc.

How to choose an electrical cable for warm water supply

The internal cable for heating the water pipe according to the type of use is divided according to the power indicators. For use in the domestic highway of a short extension it is better to put low-power heating kit. For example, for country houses and cottages use mechanisms for heating with a capacity of 50 watts per meter of pipe.

The amount of heat loss depends on the volume of the pipe and the quality of the thermal insulation layer. For example, a metal pipe with a 50 mm insulation by 20 mm is effectively heated by a heating device with a power of 21 W / m.

On an important main line for heating, put a cable system with high power. Before installing such a cable system, you should know that the power in the heating wire is selected in accordance with the diameter and length of the trunk line. But, the electricity consumption for heating in this case will be appreciable.

Watch the video

The most popular among professionals are the products of "Raychem" (Germany). This trading range is represented by a variety of models that are used not only in industrial plants, but also in domestic pipelines.

Any cable set that this manufacturer offers is characterized by a higher price than comparable versions from other manufacturers. But this is completely compensated by the functions that it performs.

Also, professional masters in the line of high-quality goods rank the Russian company "Yulmart", which quickly gained popularity among consumers.

Particular attention deserves a kit for heating pipes "Underlux" produced in Germany. This kit, which is designed for laying inside the network, and most often used in everyday life.

This system received an expert opinion on hygienic safety, which is an indication that it is allowed to be placed in a network supplying drinking water. Heating temperature of the "Underlux" kit is under the constant system of self-monitoring.

It is not difficult to build the products of "Underlux". This is done with the help of fittings made by casting. The main advantage of this self-regulating device is the ability to independently change the parameters of the work, depending on the ambient temperature.

This advantage ensures a long and reliable operation. The kits provided by this manufacturer are characterized by high efficiency and the ability to save electricity. They can be put in the water and drainage system, in drainage systems, etc.

Overview of various manufacturers can continue for a long time. The main thing to do when choosing, is to carefully study the pros and cons of the proposed options. Also, each model is accompanied by an instruction from the manufacturers. It must also be carefully studied before work.

Watch the video

Many good manufacturers can buy a good and high-quality product, but it's better to contact a trusted company. If there are difficulties with determining the number of purchased wires, then such a calculation will help the consultants.

They, in addition, will help you choose the right product at a fair price. By the way, it is necessary to add that the best place to buy a heating pipe for pipes is the construction hypermarket "Leroy Merlin". There is always a large selection of products that are of high quality and reasonable price.

Installation work

Installation of the heating wire in the pipe must be performed by specialists. They will not only accurately determine how many meters you need to buy, but also perform the installation of a heating device in compliance with all safety rules.

Installation of the heating wire in the pipe must be performed by specialists. They will not only accurately determine how many meters you need to buy, but also perform the installation of a heating device in compliance with all safety rules.

And also for highways from other materials, it constantly functions in water and can become a source of health hazard.

Therefore, if a warm water pipe creates a professional master, then it takes into account all the finer points of the installation. And on small sections of the water supply system, this installation can be performed independently.

The rules that must be observed when installing a heating wire.

- When performing the installation, it is necessary to put a tee. At the same time, all sealing standards must be observed.

- In the adapter must be screwed a special frame.

- In the side of the installation, a heating wire of the required length is wound.

- When performing the installation, it is necessary to accurately measure the length of the pipe prepared for heating.

- Do not install the cable through the shut-off valve on the pipe.

- The entry point of the cable set in the pipe is marked with a warning sign.

- Installation must be carried out very carefully, so as not to damage the power line. If the wire is damaged during operation, it will have to be changed immediately.

- The sharp edges of the system and the thread on some parts during the installation should be sealed with tape. This will prevent damage to the heating wire.

Mounted correctly the heating cable for the water pipe inside the pipe for a long time will create an ice-free water source that will function smoothly on cold winter days.

Watch the video

Or in unheated rooms, you need to warm up. Otherwise, there is a possibility of its freezing, and in the cold period the object risks remaining without water supply. This problem is successfully solved by installing a heating cable for pipes.

It is laid by a special method inside the pipeline or wrapped around the circumference. Manufacturers offer products of various lengths (from two to twenty meters). This makes it possible to heat the ground portion of the system, or parts thereof, in the area of ground freezing.

Considering how the heating cable for pipes works, it should be noted that everything is quite simple.

The heating element is heated under the influence of a passing electric current, and it works, turning this energy into a thermal one. A characteristic feature of this product line is that they do not tolerate energy, but only accept it. The conversion is carried out without the use of fuel and oxidant.

There is such a system with specific heat release, measured in W / m. This is a power factor that stands out per unit length of the device during operation.

Features of this heating system

The heating cable for water supply pipes is arranged as follows.

- I lived inside. This is the main element of the heater for the water main. It is made of an alloy that has a high electrical resistance.

- Protective covering of the main core. Produced from an insulating polymer equipped with a solid aluminum screen. Also, this role can play a screening grid of copper wire.

- The general protective covering of heating for water supply pipes is obliged to create a reliable protection of the constituent elements of the structure from the influence of the environment.

For water supply pipes you can buy a variety of types of heating systems. In the building stores their choice is very wide. Price is based on the number of veins inside.

The simplest design for the cheapest products. But, they have a significant drawback - this is the lack of protection from electromagnetic radiation. But 2-and 3-wire heating structures have an additional core, which conducts a current.

Types of cables for heating

Depending on the scheme of heat generation, there is: a self-regulating and resistive cable, designed to heat the main. In turn, resistive subdivide into:

- linear heating cable for pipes;

- zone heater for the pipeline.

The first heating mechanism produces heat when electricity passes through the veins of heating. It can be composed of one or two cores. Also, such a heater is equipped with several cores, which have a spiral or linear shape.

Video: installation of a heating cable inside a water pipe

IMPORTANT! Cut any heating element to the dimensions of the required length can not.

Self-regulating version of heating mains, the design features resembles resistive. The only difference is the absence of insulation coating. And in different areas of heating sites, heat dissipation is different.

This is due to the resistance of the polymer, which increases with rising temperature, while reducing the release of heat. This is the effect of self-regulation, which prevents overheating and burnout of the structure.

Wiring technology

The technology of cable laying in pipes must be maintained to the smallest details. Qualitatively carried out gasket allows to create a trunk, continuously working a long period at any ambient temperature.

This technology looks like this:

- Preparation for laying. It involves cleaning the pipeline of rust and dirt.

- Cable laying by one of the selected methods of technology - pulling parallel to the pipeline, or wrapping in a spiral. In the second case, a large amount of material is required for work, but for this task it is used with a small diameter.

This gasket runs along the tube

And this is a gasket made in a spiral.

- The next step is to fasten the cable wire on the underside of the trunk with a special tape.

- Laying of insulation.

- Power connection.

Upon completion of the work on the insulation of the water pipe make marking and indicate the information about the presence of warming up the network.

Piping inside the pipeline

The heating cable for the water pipe inside the pipe prevents the liquid from freezing in the system, it is activated when the ambient temperature drops to + 5 degrees. It is necessary that protection be ensured inside the water supply with a subsequent reduction of the ambient temperature.

The heating cable for the water pipe inside the pipe prevents the liquid from freezing in the system, it is activated when the ambient temperature drops to + 5 degrees. It is necessary that protection be ensured inside the water supply with a subsequent reduction of the ambient temperature.

IMPORTANT! It is not recommended to connect the heating inside the water pipe at minus temperatures, because additional time is required for defrosting the iced line. For this period, the pressure inside the water pipe is significantly reduced.

The outer covering of this heating device is made in a seamless way, this provides a reliable protection against liquid ingress, from chemical influence and temperature change.

The thermal limiter performs the following tasks:

- temperature control in the pipeline;

- turning off the power when the temperature rises above + 15 degrees, and turning on when the temperature drops to +5 degrees, this effectively saves electricity costs.

Pitching outside the pipeline

The heating cable for the water pipe outside the pipe is stretched in cases where it is impossible to lay it inside. For example, in a highway with drinking water.

The heating cable for the water pipe outside the pipe is stretched in cases where it is impossible to lay it inside. For example, in a highway with drinking water.

The outside of the pipeline wires for its heating, stretch without much effort. They should be snug against the highway. This is easily achieved with an adhesive tape made of aluminum (plastic adhesive tapes are not recommended).

Video: heating of a waterpipe

First they are attached to the pipeline with small pieces of tape, holding an interval of thirty centimeters. After this, the fastening along the longitudinal part is carried out, for this, aluminum tape is also used. This way the contact with the heat-insulating material is prevented and the heater is firmly fixed.

Pulling the heat cable outside the pipeline, you need to cover the entire surface of the pipeline with foil. This is done so that the heat is distributed evenly.

The splice clutch outside the pipeline is also installed by means of an adhesive tape made of aluminum. And the thermoregulator sensor is placed in the middle of the lines of the heating device.

Near the fittings and cranes, warming is stretched along. They must remain accessible for repair and maintenance. If this is not foreseen, then it is necessary to trim the heating circuit.

Mounting Features

Video: Installation of a heating wire for heating the water pipe with your own hands

The heating cable connection is carried out as follows:

- In the area of the heating input into the pipe, put the tee.

- It connects the pipe side.

- It starts the heating device. From inside, only pipe products with a volume of less than 2 cm can be heated.

- After this, the length of the pipeline planned for heating should be measured as much as possible. The length of the device that is connected must be the same with the length of the pipe structure.

- When the cable is connected, it does not pass through the stopcocks.

- After the installation, it is advised to put an inscription - a warning about the presence of a heat cable in the pipeline.

- You can not attach the heating device and the fastening coupling by means of oil seals.

- All actions are recommended to be done with special care and attention, so that the protective coating does not break. Parts such as the thread of a fitting are equipped with pointed edges. During installation, it is better to cover the factory tape.

- The cable for heating the pipe can be placed on a system located below the freezing point of the ground.

- After pulling the device for warm-up,.

This significantly reduces heat loss. When pulling the heat cable, it is advised to use the values of the minimum insulation thickness.

- On the pipeline and a recess with it I carry out special notes that inform me that a warming-up system is going on in this place. A sign with such an inscription must be put.

- The heating cable for pipes is not allowed to stretch at temperatures below fifteen degrees.

- The bending diameter of the heating device can be not less than its 6-dimeters.

- The anti-frost protection system must have a trip device, it is selected accordingly by the PUE.

- To put the heating mechanism without a braid - protection on synthetic tube materials and coatings within the limits of safety is not allowed.

- When the heating element is mounted, it is recommended to measure its resistance.

The heating cable for stormwater inside the pipe protects the drainage network in the winter from destruction. Correctly organized heating of the drainage system makes it possible to protect people's lives from the fall of ice from the roof and allows you to save money on annual roof repairs.

It looks like this.

Various systems are used to warm up the downpour, but at the heart of each of them is the use of a special heating cable. Livnevku is equipped with both heating devices of resistive and self-regulating type.

More preferable is called self-regulating type of devices that react to the change in ambient temperature and change the degree of their heating.

Both types of cables can provide effective heating of the roof and rainwater in the middle, and each of them has its own advantages. For example, resistor devices are an order of magnitude lower, but self-regulating species consume electricity more economically.

How to choose the right cable for heating pipelines

A specific internal heating cable for pipes is selected in accordance with the purpose of the particular network. For example, for household tasks in a country house you can use an internal heating element of a small extent.

Video: all about heating the pipeline by cable path

The power of this heater is within 60 W / m. Exceed these figures is not worth it. Experts argue that an increase in these indicators - this is unnecessary financial costs, because, these values are enough to melt the ice-cold system in an economical way.

The most common is a self-regulating heating type. Its power is determined by two parameters that necessarily indicate when labeling, this is:

- state of rest;

Buy an internal heating cable is not difficult. This can be done at any construction store. If you have any doubts when buying, it is better to resort to the help of specialists. Wizards will help you purchase an internal heater, and if necessary, quickly install it.

The heating cable for pipes is the most effective solution for the integration of any heating network. Such use allows you to get a really effective result and economical heating. Successfully solve this problem allows the heat cable, which today can be purchased with the necessary technical characteristics.

The heating cable has found wide application in other industries:

- when the tanks are heated;

- warming up the concrete;

- heating equipment in production.

Extensive use of heating devices became possible, due to their low cost and speed of installation work.

Heating cables for pipes have been used recently, but the effectiveness of this solution has made it very popular with consumers.

Video: installation of pipeline heating

The company "Profi-Cable" offers an assortment of self-regulating heating cable for water pipes. We can buy products at the manufacturer's price, with delivery and installation in Moscow.

The freezing of the pipes of the system threatens with unpleasant consequences for the stable operation of the water supply. Ice and icicles inside pipelines can reach considerable sizes. To eliminate this problem, it is necessary to involve large financial and labor resources. If in the region there are strong and long frosts, then the traditional thermal insulation is ineffective for heating. The optimal solution is to use a self-regulating heating cable for water pipes.

The heating set of wires for heating the sewage system and the water supply system is a cable product with an adjustable electrical resistance. The wire is mounted over or inside the pipe and connected to a power source. When the ambient temperature decreases, the resistance of the cable increases, which leads to a high heat release.

Advantages of cable heating of water pipes:

- universality of use. Heating cable for water supply can be connected to pipes located underground and on the street. In addition, the wire is mounted both outside and inside the pipeline;

- reliability. Correctly carried out calculation and installation of heating wires will protect the pipeline from freezing during the whole period of system use;

- economy. The power of the heating device is regulated independently, which allows to save on installation of an additional set of equipment;

- safety and ease of operation. To use a wire, it is enough to connect it to a power source.

Two technologies are used to fix the heating system of water pipes:

- Installation inside the pipeline. Wires for such installation should have a high degree of electrical protection (not lower than IP68), a non-toxic shell and a tight end clutch.

- Outdoor installation of heating cable for water supply. It is carried out in the following ways: spiral, parallel, wavy. In the first case, the pipe is braided with a wire. In the second case, the cable is mounted along the pipe. Wave-like mounting is used when the previous circuits can not be used.

Why is it necessary to choose a self-regulating heating cable for a water pipe?

This heating element, in contrast to cheaper resistive analogs, changes its properties depending on the surrounding temperature: the stronger the frost, the greater the resistance, and hence the release of thermal energy. During the thaw period the process is repeated, but in the reverse order.

The use of a self-regulating heating cable provides the following advantages:

- reliable protection of the water supply system from freezing in any frost;

- saving power consumption;

- reduction of operating costs.

When installing it, no additional control equipment is required.

If you plan to purchase a certified heating cable for water at a wholesale price, please contact our company. In addition, we provide services for the design and installation of heating systems.

The problematic area of life support for a private house is the water supply system, since there are many difficulties in terms of water supply, for example, in winter. The main obstacle here is the fact that pipes can simply freeze in winter. Although they can be located below the freezing point of the ground, but it does not completely avoid problems, since the place of entry of the water pipe into the house is in any case critical. However, this problem is relatively easy to solve if you use the device in the form of a self-regulating cable, which makes it possible to provide constant water supply without any interruptions associated with low ambient temperatures.

Before you learn how to make heating, we learn more about the cable itself for heating gutters. The considered type is an electric belt heater, the construction of which provides the presence of parallel conductors separated by a polymer matrix. This semiconductor matrix is capable of releasing heat due to the fact that in its middle there is a heating cable for the water pipe, which contributes to the continuity of heating. Features of this product are as follows:

Principle of operation

Heating cables of the type under consideration, that is, focused on the automatic regulation of the heat produced, have in their composition a polymer matrix, which is a resistance element capable of differently opposing the current depending on the degree of its heating. The actual heating of the matrix is due to the fact that it is in contact with two conductors that give off heat due to the current flowing through them. When the matrix is heated, its resistance increases, and the current decreases.

In this connection, it is possible to achieve a certain balance between the power consumption of the self-regulating cable and its temperature. For example, a lower ambient temperature leads to more power release, which is also natural in the reverse order. The cable for heating the water pipe can be in an environment that differs in its characteristics in different sections, so the temperature of the cable will not be the same either.

As a result, it is possible to achieve the effect of self-regulation, when the energy released by one wire is not uniform over its entire length. If certain areas are in a cold environment, then more energy is released, and if in warm, then less. This same effect avoids overheating of certain sections of the cable, which is provided by their different responses to changes in the temperature background.

The current is closed in a self-regulating cable by means of a matrix in parallel. This provides the possibility of connecting a voltage of 220 V (working) to the cable without limiting its length. Although this is more theory, since there are restrictions, but they are more closely related to the current load and inrush current parameters, which have acceptable values for copper busbars. Failure to comply with these parameters can lead to the destruction of contacts that serve to connect copper busbars and polymer matrix. The values of the starting current of the system exceed the nominal current by two or three times. The possible length of the sections is 60 to 100 m, depending on the type of cable used.

Positive moments of self-regulating cables

Classes of cable depending on temperature

Thermocables are divided into three classes:

- Low-temperature - suitable as a protection of pipe pipes from freezing, as well as in cases where it is necessary to produce thawing of a pipeline of small diameter. The maximum heating parameter is 65 ° C, and the specific power is 15 W / m.

- Medium temperature - provide heating of drainpipes, thawing of the roof and frozen pipes having an average diameter. Heating up to 120 ° C with a power of 10 to 33 W / m is guaranteed.

- High-temperature - cables of this kind are used in industry, so they are capable of heating up to 190 ° C at a power of 15 to 95 W / m.

With braiding or without: which is better?

Thermocables are available with or without braiding, which determines the different characteristics of the final product. A cable that does not have a braid is the cable itself and only one layer of insulation that is external. The absence of a braid significantly reduces the cost of this product.

In the case of a thermal cable supplemented by a braid, which consists of copper wire, everything changes radically - the product acquires new properties. In particular, it becomes stronger and more reliable, and the braid also provides grounding. At the same time, its cost significantly increases.

What capacity is required?

To buy a high-capacity thermal cable without justifying this purchase in terms of its relevance is an unreasonable waste of money. The equipment must meet the needs. If the power of the product remains unclaimed, then the empty electricity consumption will increase.

To buy a high-capacity thermal cable without justifying this purchase in terms of its relevance is an unreasonable waste of money. The equipment must meet the needs. If the power of the product remains unclaimed, then the empty electricity consumption will increase.

The power must be selected taking into account the diameter of the pipe. The larger diameter is the greater the power of the wire. This ratio is not ideal, since there are additional parameters that affect such calculations. For example, the presence and thickness of the layer of thermal insulation on the pipe ensures a reduction in heat loss, so the cable under these conditions can be selected and less powerful. With respect to a specific range of pipe diameters, we determine the required power in each individual case:

- from 15 to 25 mm - 10 W / m;

- from 25 to 40 mm - 16 W / m;

- from 40 to 60 mm - 24 W / m;

- from 60 to 80 mm and for 110 mm pipes of sewage systems - 30 W / m;

- from 80 mm to 40 W / m.

The information given is enough to correctly determine the purchase of a self-regulating cable, which will save money.

Thermal Cabling

Self-regulating cable can be installed inside the pipeline or outside. At low temperatures, installation can not be performed, as it is possible to damage the protective layer of the polymer. The minimum permissible temperature for the installation of the thermal cable is -5 ° C. In the case where the flexibility of the wire decreases due to the temperature conditions of the environment, it is gently unwound and briefly connected to the mains, which will restore the physical properties of this product. Only then you should proceed to install it.

Internal mounting

The internal installation method applies to pipelines having a diameter of up to 50 mm, with limited access. In situations of this kind, the thermal cable is laid over the entire length of the pipeline. The entry is made by means of a stuffing box consisting of two bushings and the same number of washers, including rubber seals.

If an internal heating device is planned for the pipelines ensuring the delivery of drinking water, it is necessary to use a self-regulating cable, which is supplemented by an outer shell based on a polymer containing fluorine. Such a thermal cable must also undergo the necessary tests for compliance with sanitary and hygienic standards.

If an internal heating device is planned for the pipelines ensuring the delivery of drinking water, it is necessary to use a self-regulating cable, which is supplemented by an outer shell based on a polymer containing fluorine. Such a thermal cable must also undergo the necessary tests for compliance with sanitary and hygienic standards.

There are the following rules for the use of a heating cable, capable of regulating the temperature of heating in different areas of its surface:

- must have the same length as the length of the pipeline;

- the cable for indoor installation can not be used in shut-off valves;

- it is necessary that the pipe has a mark about the fact that it has a drainage system installed;

- the process of inputting the wire must be carried out with extreme caution in order to maintain the integrity of the outer shell;

- before laying the cable, you should take care of the fittings - their edges require closing by means of the factory tape to avoid damaging the thermal cable.

External mounting

Placement of the heating cable over the pipe is characterized by a rather wide variability of methods:

- linear - installed on small diameter pipelines in the form of a line running along the pipe;

- parallel - installation is carried out on large diameter pipelines or on water supply systems that are located in the open air; in this case, mount two or three cables running parallel to each other on the pipes;

- spiral - the cable, as it were, wraps the pipe along the line of the spiral with the pitch of the turn, depending on the parameters of power and diameter of the pipeline;

- wavy - is used as a replacement for the previous version, due to the fact that the length of the cable is simply not enough; laying a wire for heating pipes with a wavy line suggests a lower consumption of the starting material.

Due to the self-regulation function, the heating cable can be overlapped, which is used when it is necessary to heat the shut-off valves located outdoors. External laying should be correlated with requirements, the observance of which would exclude the possibility of wire abrasion and other negative mechanical effects. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off valves, for example in the form of valves.

Due to the self-regulation function, the heating cable can be overlapped, which is used when it is necessary to heat the shut-off valves located outdoors. External laying should be correlated with requirements, the observance of which would exclude the possibility of wire abrasion and other negative mechanical effects. This is usually achieved by laying the wire so that it does not interfere with the functioning of the shut-off valves, for example in the form of valves.

The thermal cable should be relatively rigidly attached to the pipeline by using aluminum tape. Upon completion of installation, the pipeline is necessarily insulated to reduce heat losses. Connect the water supply cable to the 220-240 V network only through the RCD, as described in the corresponding instruction.

What are the advantages of a cable with a thermoregulator?

Heating of the water supply system requires a significant flow of money, because the heating elements consume electricity. To reduce these costs, you should use cables equipped with thermostats. These devices are good in that they include a heating system when the temperature drops to +3 ° C, and turn it off when reaching the mark of +13 ° C.

For example, water coming from a well is unlikely to be higher than +13 ° C. As a result, the heating of pipes in this case will be carried out all year round, and this is inefficient. At the same time it is asked whether it makes sense to heat the water entering the drain tank. It is much easier to set the switch-off temperature +5 ° C and lower the costs going to the heating of the gutters.

For example, water coming from a well is unlikely to be higher than +13 ° C. As a result, the heating of pipes in this case will be carried out all year round, and this is inefficient. At the same time it is asked whether it makes sense to heat the water entering the drain tank. It is much easier to set the switch-off temperature +5 ° C and lower the costs going to the heating of the gutters.

As a result, there will also be a positive effect such as an increase in the life of the heating cables. The operation of each thermal cable occurs with the development of a resource that determines how long the product can work without losing its properties. Therefore, a shorter working time increases the life of the self-regulating cable.

Installation of heating systems equipped with temperature controllers must be related to the installation of a temperature sensor, which is determined by some complexity. The sensor must be mounted so that the heat of the heaters does not have any influence on it. It is necessary to use thermal insulation, which would serve as a barrier between the sensor and the thermal cable.

Installation of the thermostat should be done indoors. For its connection, a house electric board with an intermediate device in the form of an RCD is used. The heating cable consumes little power, therefore the suitable rating of the machine will be 6A, and the nominal value of the RCD is 30 mA. The heating cable is connected by means of special connectors on the housing.