Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

Daylight lamps (LDS) are the first economical devices that appeared after traditional lamps with filament. They relate to gas discharge devices, where an element limiting the power in the electrical circuit is necessarily required.

Assignment of throttle

The throttle for fluorescent lamps controls the voltage applied to the lamp electrodes. In addition, he has the following appointments:

- protection from power surges;

- heating cathodes;

- creating a high voltage to start the lamp;

- limitation of the electric current after start-up;

- stabilization of the burning process of the lamp.

To save the throttle is connected to two lamps.

The principle of the electromagnetic ballast (EMPRA)

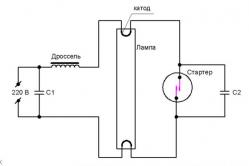

The first one, which was created and is still in use, includes the elements:

- throttle;

- starter;

- two capacitors.

The scheme of a fluorescent lamp with a throttle is connected to a 220 V network. All the parts connected together are called electromagnetic ballast.

When power is applied, the circuit of the tungsten lamp spirals closes and the starter starts in the glow discharge mode. Through the lamp, the current does not pass. The threads are gradually warmed up. The starter contacts in the initial state are open. One of them is made of bimetallic. It bends when heated from a glow discharge and closes the circuit. In this case, the current increases by 2-3 times and the cathodes of the lamp warm up.

As soon as the starter contacts are closed, the discharge stops and begins to cool down. As a result, the movable contact opens and the inductance of the throttle occurs as a significant voltage pulse. It is sufficient for the electrons to break through the gas medium between the electrodes and the lamp is lit. The rated current begins to flow through it, which then decreases by a factor of 2 due to the voltage drop across the throttle. The starter constantly remains in the off state (the contacts are open), while the LDS burns.

Thus, the ballast starts the lamp and then keeps it in the active state.

Advantages and disadvantages of EMPRA

Electromagnetic choke for fluorescent lamps is characterized by low price, simple design and high reliability.

In addition, there are drawbacks:

- pulsating light, leading to eye fatigue;

- up to 15% of electricity is lost;

- noise at the time of launch and during operation;

- the lamp does not start properly at low temperatures;

- large size and weight;

- long lamp start.

Usually the buzzing and flickering of the lamp occurs with unstable power. Ballastnik produce with different levels of noise. To reduce it, you can choose the appropriate model.

Lamps and chokes are selected equal to each other in power, otherwise the lifetime of the lamp will be significantly reduced. Usually they are supplied in the kit, and the ballast is replaced with a device with the same parameters.

Comes with the EMPRA are inexpensive, and they do not need tuning.

Ballastnik is characterized by the consumption of reactive energy. To reduce losses parallel to the supply network, a capacitor is connected. ![]()

Electronic ballast

All the imperfections of the electromagnetic choke had to be eliminated, and as a result of the research, an electronic choke was created for fluorescent lamps (electronic ballasts). The circuit is a single unit that starts and maintains the combustion process by forming a predetermined sequence of voltage changes. You can connect it with the help of the instruction manual supplied with the model.

Throttle for fluorescent lamps of electronic type has advantages:

- possibility of instant start or with any delay;

- lack of starter;

- no blinking;

- increased light output;

- compactness and ease of the device;

- optimal operating modes.

Electronic ballast is more expensive than an electromagnetic device due to a complex electronic circuit that includes filters, power factor correction, inverter and ballast. In some models, protection against the erroneous start of a lamp without lamps is established.

In user reviews it is said about the convenience of using electronic ballasts in energy-saving LDS, which are built directly into the base for conventional standard cartridges.

How to start a fluorescent lamp with electronic ballast?

When switched on from the electronic ballast, the electrodes are energized and warmed up. Then they receive a powerful impulse, which lights the lamp. It is formed by creating an oscillatory circuit entering resonance before discharge. In this way cathodes are heated well, all mercury in the flask evaporates, so that a light bulb starts up. After the discharge occurs, the resonance of the oscillatory circuit stops immediately and the voltage drops to the working one.

The principle of operation of electronic ballasts is similar to the option with an electromagnetic throttle, since the lamp is started which then decreases to a constant value and maintains a discharge in the lamp.

The current frequency reaches 20-60 kHz, due to which flicker is eliminated, and the efficiency becomes higher. In the reviews it is often suggested to replace electromagnetic chokes with electronic ones. It is important that they fit the power. The circuit can create an instantaneous start or with a gradual increase in brightness. Cold start is convenient, but the luminaire's service life is much less.

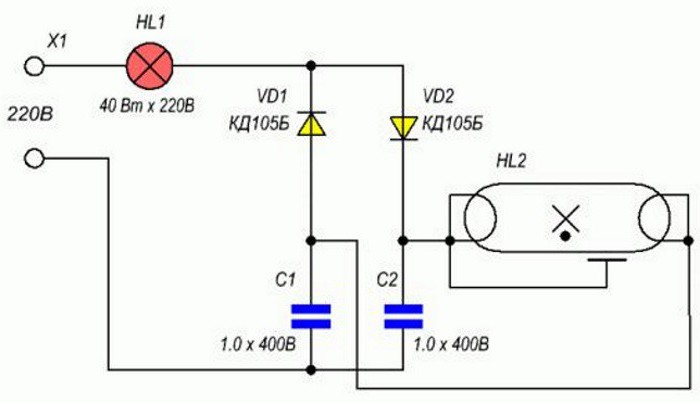

Fluorescent lamp without starter, throttle

LDS can be turned on without a bulky throttle, using instead of it a simple incandescent lamp with a similar power. In this scheme, the starter is also not needed.

The connection is made through a rectifier, in which the voltage is doubled by means of capacitors and ignites the lamp without heating the cathodes. Consistently with the LDS through the phase wire, an incandescent lamp limiting the current is switched on. Condensers and bridges should be selected with a margin of allowable voltage. When feeding the LDS through the rectifier, the bulb on one side will soon begin to darken. In this case, the polarity of the supply must be changed.

Connecting a fluorescent lamp without a throttle, where an active load is used instead, gives a weak brightness.

If instead of the incandescent lamp to install the throttle, the lamp will glow significantly stronger.

Check of serviceability of a throttle

When LDS is not lit, the reason lies in the malfunction of the wiring, the lamp itself, the starter or throttle. Simple causes are identified by the tester. Before checking the choke of the fluorescent lamp with a multimeter, turn off the voltage and discharge the capacitors. Then the switch of the device is set to the continuity mode or to the minimum limit of the resistance measurement and determined:

- coil winding integrity;

- electrical resistance of the winding;

- interturn closure;

- break in the coil winding.

In the reviews it is suggested to check the throttle, connecting it to the network through an incandescent lamp. When the interturn closure, it burns brightly, and serviceable - in full.

If a malfunction is detected, the throttle is easier to replace, since repairs can be more expensive.

Most often the starter is broken in the circuit. To verify its functionality, a known good is installed instead of it. If the lamp does not light up, then the reason is different.

The throttle is also checked using a serviceable lamp, connecting two wires to its base from it. If the lamp lights up bright, then the throttle is functional.

Conclusion

Throttle for fluorescent lamps is being improved in the direction of improving performance. Electronic devices begin to displace electromagnetic. At the same time, old versions of models continue to be used due to their simplicity and low price. It is necessary to understand all the variety of types, to operate them correctly and to connect them.

* This page is created for those who do not know what the "Throttle" is in the car.

To better understand the reasons for the poor dynamics of acceleration and increased fuel consumption, you need to understand what a choke or throttle assembly is in a car.

What is a choke?

The engine needs oxygen. Air supply you regulate with the help of an accelerator. In people, the accelerator is called the gas pedal. The gas pedal is connected to a device called a throttle assembly or simply a throttle.

There are two kinds of throttle. Mechanical and electric. The mechanical throttle is directly connected to the throttle by means of a cable. The photo shows a mechanical throttle. And there you can clearly see a large hole closed by a throttle.

How does the choke work?

When you start driving a car or "podataet gas" you press the gas pedal. The car rides faster, the car rides slowly. By pressing the accelerator pedal, you set in motion throttle valve, and thus regulate the supply of air to the engine. And at the same time supply of fuel.

The picture shows the conventional throttle circuit. Hover over the picture to understand the principle of work.

The throttle valve is connected to the throttle position sensor. And the position of the flap tells the computer how much fuel to feed into the engine.

When the gas pedal is pressed, air enters the engine and mixes with fuel, and this explosive "cocktail" enters the combustion chamber where it is set on fire. Larger doses of ingredients, the car rides faster. Small - slower. In such an uncomplicated way, with the help of the gas pedal, you measure the amount of fuel "cocktail" and set the dynamics of the car.

Where is the choke?

You raise the hood and find the air filter housing. From the air filter there is, as a rule, a rubber air duct. But maybe a plastic one. This duct just connects to the throttle. That is, the throttle is located between the air filter and the engine. And it is attached to the engine.

If you look under the hood and see the end of the cable, which is attached to the throttle lever, then this will be the same - a mechanical throttle (see photo).

If you found a throttle, but with all the diligence you did not find the cable, then your car has an electric choke. It is often called electronic. The electric choke is controlled by an electrical signal. On the features of the electric throttle and its effect on the dynamics of the car acceleration, see pages:

- tupit auto ...

- it is interesting

On page "it's interesting" there is an additional description and comparison of the electric and mechanical throttle. And also described the effect after the completion of the throttle.

Someone happens that the car "thinks" before hastening, after the driver pressed the gas pedal. The next page of the site is devoted to this problem. A further description and comparison of how electrical and mechanical throttles affect the dynamics of the car's acceleration.

The design of the fluorescent lamp is such that without a ballast, it will be very difficult to organize its operation. To do this, previously used electromagnetic ballast or EMPRA (its main element - the throttle), and today it replaced a more advanced version - electronic ballast (electronic ballast). Despite this, today both kinds of devices are still in operation.

Where else is applied?

The throttle is used less and less, perhaps, over time it will become obsolete as useless. After all, connecting a gas-discharge lamp in this way is the main area of application of this device. The throttle plays a decisive role in the operation of the fluorescent lamp, since it creates acceptable conditions for the operation of the lighting device of this type: it keeps the rising current at a certain level, which allows maintaining a sufficient voltage value on the electrodes in the flask.

This feature turns the throttle into a ballast. In addition, the connection diagram of the fluorescent lamp contains one more element - a starter. He is responsible for breaking the circuit.

This leads to the emergence of EMF self-inductance in the throttle, which, in turn, helps to increase the voltage to 700-1000V. The result of these processes is a breakdown and the inclusion of a fluorescent lamp.

Principle of operation and species overview

The throttle device for gas-discharge lamps is quite simple: in fact, it is an inductor with a ferromagnetic core. Such a device is used only if the circuit involves connecting the lamp with an electromagnetic ballast. The electronic ballast contains a stabilizer and a frequency converter in its design, these elements allow lighting the light, since they realize the functions of the throttle and the starter.

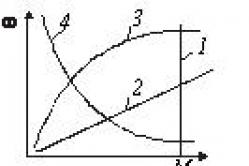

To answer the question why a choke is needed, it is recommended to first understand the principle of its operation. When switched on, a phase shift occurs between the main electrical parameters: voltage and current. This lag is determined by a characteristic such as cosφ (power factor). When calculating the calculated value of the active component of the load, this value is taken into account. If the power factor is small, the load level increases. Therefore, a capacitor with a compensating function is also included in the circuit.

Using this element (3-5 μF) with a power reaching 36 W, you can achieve an increase in cosφ to 0.85. The minimum power limit of fluorescent lamps in this case is 18 W. The capacitance of the light source 18 W and 36 W can be the same. The level of the throttle-held load must correspond to the power of the light source.

There are several versions of such devices, each of which differs in magnitude of power loss:

- D (normal);

- In (lowered);

- C (the lowest).

The principle of the throttle assumes the consumption of part of the power is not for its intended purpose, but for heating the device. Useful work is not performed at this, which means that the level of losses determines the efficiency of the operation: the higher this value, the hotter the throttle for connecting the fluorescent lamp is heated.

The main advantages

Despite the fact that today the popularity of the EmPra has decreased noticeably, such devices are still used. This is due to a number of advantages:

- ensuring the safe operation of the fluorescent lamp, for which a starter is also needed;

- the ability to keep current at a certain level;

- partial stabilization of the light flux, but the principle of the EmPRA operation is such that it is impossible to completely remove the flicker of the gas-discharge lamps;

- affordable price.

It is thanks to the last factor from the above, the ballast-type electromagnetic-type device with the throttle is still used today. In addition, these devices are easy to install and easy to use.

If there are problems in the operation of lamps connected via a choke (for example, they do not turn on), the circuit is checked for errors and the quality of the connection (connection, wire breaks).

In the case when there are no apparent reasons, it is necessary to check the serviceability of the throttle. You can do this by connecting an incandescent lamp. At a breakage the light source does not burn, at витокковом closings - shines in full force. Normal mode of operation - vpnnakala.

Options for switching on fluorescent light sources

The scheme for connecting lamps of this type through a starter and a choke is as follows:

Wiring diagram

You can choose an option with a compensation capacitor or without it, it all depends on the power factor. From what type of starter is used, the number of consecutive lamps will depend:

It is considered that without a ballast it is impossible to switch on a gas-discharge lighting device. This is not quite true. If you change the scheme, then the switchless connection is realistic. To ensure normal operating conditions of a fluorescent light source, the mains voltage must be doubled and rectified, for which a rectifier is introduced into the circuit. And instead of ballast, a miniature incandescent lamp is used, a resistor or capacitor is not suitable for this purpose.

Directly, the connection through a light source with filament and rectifier:

Thus, gas-discharge lamps, in particular, luminescent designs, will work if they provide a ballast for them. Depending on its type (electronic or electromagnetic variant) it is possible to provide a different level of lighting efficiency. The EMPA includes a throttle and a starter.

The first of the elements creates normal conditions for the functioning of the light source (restrains the operating current at a certain level), therefore it is considered that without it the lighting will not work. But there is an alternative - a power scheme without a throttle, but with a double voltage of the power source.

The main elements of the scheme for incorporating a fluorescent lamp with an electromagnetic ballast are a throttle and a starter. A starter is a miniature neon lamp, one or both electrodes of which are made of bimetal. When a glow discharge occurs inside the starter, the bimetallic electrode heats up and then, bending, shortly closes with the second electrode.

After applying voltage to the circuit, the current through the fluorescent lamp does not flow, since the gas gap inside the lamp is an insulator, and for breakdown it needs a voltage exceeding the supply network voltage. Therefore, only the starter light, whose ignition voltage is below the mains, is lit. The current value of 20 - 50 mA flows through the throttle, the electrodes of the fluorescent lamp, the neon lamp of the starter.

The starter consists of a glass cylinder filled with an inert gas. The metal soldered and bimetallic electrodes with soldered ends passing through the plinths are soldered into the cylinder. The cylinder is enclosed in a metal or plastic casing with a hole in the top.

Scheme of glow discharge starter device: 1 - leads, 2 - metal moving electrode, 3 - glass cylinder, 4 - bimetallic electrode, 6 - base

Starters for the inclusion of fluorescent lamps in the network are produced for 110 and 220 V.

Under the influence of current, the electrodes of the starter warm up and close. After the circuit is closed, a current flows in excess of 1.5 times the rated current of the lamp. The magnitude of this current is limited mainly by the resistance of the throttle, since the electrodes of the starter are closed, and the lamp electrodes have little resistance.

Elements of the circuit with a throttle and a starter: 1 - terminals of mains voltage; 2 - the throttle; 3, 5 - lamp cathodes, 4 - tube, 6, 7 - starter electrodes, 8 - starter.

For 1 - 2 s, the lamp electrodes are heated to 800 - 900 ° C, as a result of this, electronic emission increases and the breakdown of the gas gap is facilitated. The electrodes of the starter cool down, since there is no discharge in it.

When the starter cools, the electrodes return to their original state and break the chain. At the moment of breaking the chain, the starter emits. etc. with. self-inductance in the throttle, the value of which is proportional to the inductance of the throttle and the rate of change of the current at the moment of disconnection of the circuit. Formed due to e. etc. with. self-induction, high voltage (700 - 1000 V) is applied to the lamp prepared for ignition (the electrodes are heated). A breakdown occurs, and the lamp begins to glow.

To the starter, which is connected in parallel to the lamp, approximately half of the mains voltage is applied. This value is not enough to break a neon light, so it no longer lights up. The entire ignition period lasts less than 10 s.

Consideration of the process of igniting the lamp allows you to clarify the purpose of the main elements of the circuit.

The starter performs two important functions:

1) short circuits in order to warm up the electrodes of the lamp with an increased current and to facilitate the ignition,

2) breaks the electric circuit after heating the lamp electrodes and thereby causes a voltage pulse that ensures breakdown of the gas gap.

The throttle performs three functions:

1) limits the current when the starter electrodes are closed,

2) generates a voltage pulse for breakdown of the lamp due to e. etc. with. self-induction at the time of opening of the starter electrodes,

3) stabilizes the burning of the arc discharge after ignition.

Scheme of pulsed ignition of a fluorescent lamp in operation: