Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

Every day the popularity of lamps daylight as a source of illumination only grows. This is due to their high duration of work and high-quality luminescence.

Fluorescent lamps do not work directly from a network with a voltage of 220 volts. For their functioning, a special unit called ballasts (ballasts) is required. The design of the unit includes three basic elements, which include: a choke (inductor with a core), a smoothing capacitor and a starter. This is how we will talk about the last device today.

I greet all friends on the site "Electrician in the house," recently I had to look for the cause of the malfunction of luminaires with fluorescent lamps, which consisted in a malfunction of the gear element, so the next issue will be devoted specifically to starter fluorescent lamp. We will analyze its purpose, the device and the functions to be performed.

The device of a starter of fluorescent lamps

The design of this element is quite simple. Each model, produced by a certain manufacturer, has its own specifications. This should be taken into account when choosing lamps. A starter is a glass cylinder inside which there is an inert gas. It can be a mixture of helium with hydrogen or neon. The stationary metal electrodes are soldered into the cylinder. Their conclusions pass through the plinths.

The balloon is located inside a plastic or metal case, which has an opening on top. The most popular material for making the case is plastic. Coping with high temperatures to such a housing allows a special impregnation. Anyone has only two legs (contacts).

If you remove the structure from the body you can see the flask itself. It is also seen that some element is connected parallel to the electrodes of the bulb - it is a capacitor. Its capacity is of the order of 0.003-0.1 μf. The capacitor is designed to perform two functions at once:

- - fights with radio interference, which arise from the contact of electrodes, by reducing their level.

- - involved in the process of igniting the lamp.

The capacitor reduces the voltage pulse, which is formed when the electrodes are opened, and increases its duration.

Due to the parallel inclusion with electrodes the capacitor reduces the probability of their welding (sticking). A similar phenomenon can occur in the process of opening the electrodes due to the formation of an electric arc. Condenser in the shortest time extinguishes the arc.

Why do I need a starter in fluorescent lamps

This element is basic in construction fluorescent lamps. Without it, electromagnetic ballasts will not be able to function. The main purpose of the starter is to start the engine and ignite the inert gas in the gas discharge bulb. The starter works as a switch - opens and closes the electrical circuit.

The installation of the starter is dictated by the need to perform two important functions:

- - circuit closure. Allows to heat the lamp electrodes, thereby facilitating the ignition process;

- - break the chain. Occurs immediately after heating the electrodes. As a result of the opening, an impulse increased voltage, which is the cause of breakdown of the gas gap of the bulb.

The throttle plays the role of a stabilizer and a transformer. It maintains the required current of the lamp filaments, creates a voltage pulse necessary for the breakdown of the lamp and stabilizes the arc combustion process.

How the fluorescent light works

When the circuit is connected to the electrical circuit all voltage is applied to . In the normal position, the electrodes are in the open position. On the electrodes of the starter begins to emit a glow discharge. A small current flows through the circuit (30-50 mA).

This current is sufficient for heating the electrodes. When a certain temperature is reached, they begin to bend and close the chain. After the contacts close, the glow discharge stops.

Let's take a look at some of the main details of the lamp itself.

When the circuit is closed (via the starter electrodes), a current begins to flow through it, the value of which is 1.5 times the rated current of the lamp. The magnitude of the current is limited by the resistance of the throttle. Lamp and starter electrodes can not perform this function, because the first have insufficient resistance, and the latter are in the closed position.

Heating of electrodes up to 8000С occurs within 1-2 seconds. As a result of the increase in temperature, an increase in the electron emission occurs, which facilitates the simplification of the process of breakdown of the gas gap. The discharge in the electrodes of the starter is absent and they gradually cool down.

After the starter is cooled, the electrodes open, taking their initial position, and break the chain. The discontinuity of the circuit is accompanied by the appearance of self-induction in the choke of the EMF. Its value is directly proportional to the inductance of the throttle and the rate of change in the magnitude of the current when the circuit is broken.

The onset of EMF of self-induction is the reason for the creation increased stress the value of 800-1000 V, which in the form of a pulse is fed to the lamp. Its electrodes are preheated and ready for ignition. At this moment, a breakdown occurs and glow begins.

The starter which is connected in parallel to the lamp is now subjected to a voltage, the value of which is half the voltage of the network. It is not able to break through a neon bulb, hence its ignition is no longer carried out. The entire ignition cycle lasts no more than 10 seconds.

How to check the starter of a fluorescent lamp

This issue often arises before the experts in the repair process fluorescent lighting fixtures. Although the detail is small, it can cause serious problems.

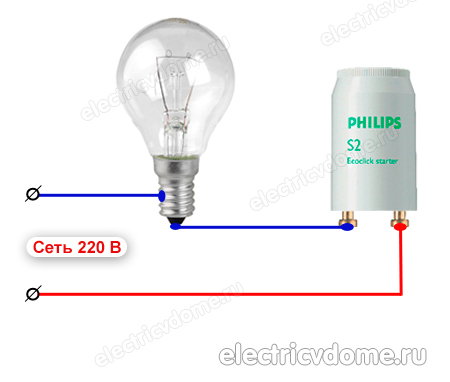

Detect the failure of the starter can be replaced by a working one, if one is at hand. And here's what to do in cases where there are no more lamps next door, and the nearest specialized store is not one kilometer of the way? How to check the starter of a fluorescent lamp at home? The device can be tested in accordance with the standard scheme.

Consistently with the starter, an ordinary lamp with a filament is connected to the mains. It is desirable that its power does not exceed 40 W.

It is not difficult to assemble such a scheme. If the starter is in good condition, the lamp will burn and periodically extinguish for a moment. This process will be accompanied by characteristic clicks that indicate the work of contacts. If the bulb does not light up or glows constantly (without blinking), then it is possible to ascertain the failure of the starter.

So here's a simple way you can check starter for fluorescent lamps. Although, in truth, I have not yet seen that in the production of them wherever they are checked. This is probably due to their insignificant cost. Usually it happens like if the lamp does not work or starts to flash just change the starter to a new one, it turned out to eliminate the cause well, there is no meaning to the problem in the other.

Why does the fluorescent lamp flash

Dear friends, you probably noticed that fixtures with fluorescent lamps begin to flash with time. And this is not due to the use of switches with illumination which are the cause flashing energy saving lamps.

In the process of operating lamps, the operating voltage of the glow discharge in the starter drops. This is the reason that the starter will fire even when the lamp is on. After the electrodes are opened, the glow is restored. The human eye perceives this as a process of blinking. A similar phenomenon is the cause of damage to the lamp and the failure of the throttle as a result of its overheating.

Therefore, if you notice a permanent flashing of the lamp, replace starter with new one. In 90% of cases it is he who causes this phenomenon.

If there is a flashing, it is necessary to replace the starter as soon as possible, since in this mode of operation the resource of the components of the luminaire will decrease and the flask or throttle can exit.

The throttle is characterized by certain parameters. Since it is sometimes an essentially nonlinear element, its parameters are not unambiguous. They can be divided into two groups: nominal, characterizing the throttle as an independent product, and design, characterizing it as an element of a specific scheme.

The nominal parameters of the throttle should be found or determined under strictly stipulated conditions. We will determine them with a sinusoidal voltage at the terminals of the winding, indicating the magnitude of the voltage and frequency.

Nominal parameters must fully guarantee the life of the throttle and its reliable operation in a particular circuit. Although the nominal parameters of the throttle do not determine the electrical regime in the circuit into which it can be switched, but they fully characterize the throttle as an article and at the same time are related to its design parameters.

The main nominal parameters of the throttle, which must be specified in his passport, are as follows:

The frequency of the current is f, Hz.

Nominal (maximum permissible) value of the throttle current I, a.

Inductance of the throttle at nominal

Resistance of the winding of the "cold" throttle

Loss in the core of the throttle

Throttle weight G, kg.

Other nominal parameters of the throttle are: the maximum permissible value of the harmonic coefficient in the curve of the rated current; the maximum permissible overtemperature of the winding of the throttle grad (at a certain ambient temperature); overall throttle power and its reactive power factor Q; technical and economic indicator of the throttle coefficient of the throttle screening.

We explain the parameters and A; the throttle parameters will be considered in Sections 1.5 and 1.6.

1. Rated throttle inductance

The nominal inductance of the throttle is given by

![]()

where f and - the frequency and the effective value of the sinusoidal voltage applied to the winding of the throttle;

I is the effective value of the rated current;

Angle of phase shift between voltage and equivalent current sinusoid.

For small values of the ohmic resistance of the winding of the throttle and the losses in its core, the nominal inductance can approximately be determined from formula

![]()

The magnitude of the inductance (1.1) of a nonlinear throttle is not constant, but depends on the magnitude of the applied voltage and the frequency of the current. Therefore, the throttle as an independent product must be characterized precisely by the value of its nominal inductance, measured under completely defined and specified in the passport conditions. Only such an inductance is a characteristic parameter of the throttle. The value of the inductance of the throttle is recommended to be indicated in the passport with indications of the effective value of the sinusoidal voltage in the form of indices, for which it is determined, for example, etc.

2. Curve factor of the rated current curve

Due to the nonlinearity of the throttle, due to the properties of its ferromagnetic core, the current in the winding is not sinusoidal. The current curve even with a sinusoidal voltage has a distorted, pointed shape (Figure 1.3). The presence of higher current harmonics can in some cases have a harmful effect on the operation of certain devices, while in others this property of chokes is of benefit.

Fig. 1.3. Voltage oscillograms at the terminals of the throttle (a) and the current in the winding (b).

To quantify the distortion of the current curve for non-sinusoidal voltage, the nonlinear distortion coefficient is used. It is defined as the ratio of the square root of the sum of the squares of the amplitudes of all harmonics to the amplitude of the useful component of the entire harmonic spectrum.

At a sinusoidal voltage, the distortion factor is called the harmonic coefficient. It is the ratio of the square root of the sum of the squares of the effective values of all harmonics, with the exception of the useful harmonic, to the effective value of the useful harmonic. If the fundamental, first harmonic is useful, then the harmonic coefficient

where is the effective value of the harmonic current.

If the harmonic (or the sum of the harmonics) is not the first harmonic, then the rms value of all harmonics should be in the numerator of the fraction, except for, and in the denominator - the effective value of the corresponding harmonic.

The harmonic ratio is measured with special instruments at the nominal throttle current. Typically, the throttles are designed with a magnitude

3. The shape of the voltage curve

The voltage applied to the clamps is estimated by the shape of the curve, which is the ratio

![]()

where, respectively, the acting and average values of the voltage.

4. Throttle Capacities

It is necessary to distinguish two power of the throttle - the overall power and the design reactive power Q. The overall power of the throttle means the value

![]()

under rated reactive power - the value

![]()

where is the distortion coefficient of the shape of the current curve.

The value determines the dimensions of the core of the throttle. Knowing the required size of the overall power of the designed throttle, you can choose for it a normalized core. Note that for ordinary throttles, the values of Q and Q differ insignificantly. The nominal values and Q should be measured at the rated voltage and frequency.

5. Throttle quality and angle of loss

These parameters characterize the quality of the throttle in terms of losses in it. The higher the quality factor and the smaller the angle of loss, the better the quality of the throttle. Note, however, that the higher the Q-factor of a choke, the greater its size and weight.

The throttle quality factor is equal to the ratio of the reactive power of the throttle to the sum of the losses in its core and winding:

It is convenient to introduce the notion of particular Q-factors, or, in other words, about Q-factor and Q-factor

![]()

The Q-factors are related by the following relationship.

Fluorescent lamps are now at the height of popularity. They are used in hospitals, schools, kindergartens and other public institutions. Fluorescent lamps have many advantages over conventional lamps:

The device of starters and throttles and a principle of their work

Starter consists of a small glass flask filled with gas. The bulb is placed inside a metal or plastic housing. On the underside of the starter, there are two electrodes that directly come into contact with the lamp wires during operation. There is sometimes a window at the top of the starter. Starters often fail, but they are very easy to replace, because they are removable.

Throttle is a coil in a metal shell. By power is set the same as the lamp itself. Without the throttle, the lamp will not work. The throttle ignites the mercury vapor in the lamp and limits the current flow. The throttle stabilizes the mains voltage if it is above the rated voltage.

The principle of the starter and throttle is that one element (starter) starts the electrodes, and the throttle supports this work. When the current is switched on in the circuit, the starter is first switched on. It heats the electrodes, increases the supply of current to the device, the bimetallic starter plate is heated. After the electrodes have warmed up, the contact opens and the current is transferred to the throttle. The throttle accumulates the voltage for some time, the gas in the flask breaks and the lamp lights up.

During operation, the current is evenly distributed between the throttle and the lamp, which ensures stable operation even under the condition of increased voltage. The throttle does not expend energy on itself, it just accumulates it and converts it.

Without a starter, basically, it is impossible to turn on a lamp using certain chokes. It just will not burn. While in the future operation of the lamp, the starter is not needed. You can even pull it out, if necessary, and check it or replace it while the lamp is running. But the subsequent inclusion will require a starter. It is also possible to work the lamp without a starter, directly. In this case, the lamp is lit by a cold start, which significantly reduces its service life. The throttle ensures the operation of the lamp. Without it, the lamp will not work.

Types of starters

- Starters of a glowing row - a lamp with bimetallic electrodes. These starters are more often used, because they have a simplified design and a relatively short ignition time.

- Thermal starters - characterized by an extended ignition time, due to which the electrodes heat longer, which positively affects the operation of the lamp. However, such starters have a more complex structure, they also consume additional energy for themselves, the circuit of their connection has a complex structure.

- Semiconductor starters. Their work is built on the principle of a key. After heating the electrodes, the voltage opens and a pulse occurs in the bulb.

Varieties of chokes for fluorescent lamps

- Electromagnetic chokes - connected in series with the lamp. The electromagnetic throttle requires a starter, that is, a cold start will not be possible. They have a very big drawback - during operation, the lamp flickers.

- Electronic chokes are a relatively recent invention. Its incomparable advantage is a simplified connection scheme, as its starter does not need a starter. Due to such chokes the flickering of the lamp decreases, at start-up the lamp does not pulsate. Noise is diminished when the lamp is operating.

Which manufacturer is better?

Here you can not give an unambiguous answer. Each manufacturer of elements for the operation of fluorescent lamps is trying to produce good products. Therefore, the choice will be based on the results of personal experience or the experience of friends. The most famous manufacturers of chokes - Chilisin, Luxe, Vossloh schwabe, Navigator, starters: perhaps the most popular manufacturer, - Philips. Basically, the chokes and starters come complete with a lamp. If you need to buy spare parts, or replace blown items, you can choose one of these manufacturers.

Here you can not give an unambiguous answer. Each manufacturer of elements for the operation of fluorescent lamps is trying to produce good products. Therefore, the choice will be based on the results of personal experience or the experience of friends. The most famous manufacturers of chokes - Chilisin, Luxe, Vossloh schwabe, Navigator, starters: perhaps the most popular manufacturer, - Philips. Basically, the chokes and starters come complete with a lamp. If you need to buy spare parts, or replace blown items, you can choose one of these manufacturers.

Service life of starters and chokes

As the manufacturers say, the starter must withstand at least 6,000 inclusions of the lamp. The operating range should be from + 5 ° C to + 55 ° C. Chokes under normal operating conditions should work for about 3 years. Again, it all depends on the manufacturer and the probability of getting married.

How to choose a starter and choke

First you need to decide what type of launch you will have. If you use electronic chokes, the starter will not be needed. When choosing electromagnetic chokes you need to think about buying a starter, because without it the lamp will not burn.

- Choose a proven manufacturer, do not pursue cheapness.

- Take it immediately with a reserve - suddenly you get a defective or poorly working part.

- If you do not understand anything in electricity, trust this business professionals. Or consult with people who have had experience working with fluorescent lamps.

How to replace a starter

Perhaps, even a beginner can easily cope with this work. Sometimes it happens that the lamp burns for a while and goes out. So, you need to check the starter. To replace the starter, you need to turn off the lamp and remove the cover. The spoiled starter is pulled out of the lamp by turning it counter-clockwise. To connect a new starter, just insert it into the grooves and turn it clockwise. That's all - the starter firmly stands in its place.

How to replace the throttle

Most craftsmen prefer to repair the throttle, but this will require technical skills. Therefore, it is simpler to replace the throttle. Before replacing the throttle, you need to turn off the electricity in the entire house, as simply turning off the lamp will not relieve the voltage on the lamp. After that, you can dismantle the failed choke. Remove the fasteners and disconnect the wires, through which the current goes to the lamp. Now it remains to connect the wires in the order that they were initially connected, and put the throttle in its place.