Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

Recently, in our country, people began to actively establish. And, if earlier it was more a whim than a necessity, now the obligatory existence of a counter is fixed by law. Let's figure out how heat meters work, what they are and how they are installed.

Arrangement of a heat meter

The heat meter consists of the following main elements:

- primary flow transducer (flowmeter)

- temperature sensors

- heat calculator.

Flowmeter - this is the main component of any counter. As the name implies, this device is responsible for measuring the flow of hot water entering the heating system. The meter models, which are now on the market, mainly use two types of flow sensors: tachometric and ultrasonic.

Tachometric flowmeters perform their task accurately enough, at the same time they have an affordable price. For the safety of the device, it is important that it is protected by a mechanical cleaning filter.

Ultrasonic flowmeters are very accurate and reliable, since they do not have moving mechanical parts. However, they are somewhat more expensive than tachometric ones, and for their correct operation it is necessary that before the counter and after the counter there are sufficiently long straight sections in the system (only three distances in the meter's diameter are sufficient for tachometric counters).

The temperature sensor is an immersion thermocouple and serves for recording the parameters of the coolant.

Heat calculator Is an electronic microprocessor device that analyzes the results obtained by the flow and temperature sensors and calculates the amount of heat consumed by displaying it on the display. It is according to the parameters of the heat calculator that the heating is paid: at a predetermined reference date, the current value is fixed. This determines the amount of heat consumed per month.

All received values are stored in the memory of the heat calculator. Therefore, when buying a counter, you should choose models equipped with nonvolatile memory, which is capable of storing data even with a very long power failure - up to three years. Most heat meters work from the built-in battery, which is enough for several years.

Saving heat

It is believed that the meters of a resource allow this resource to be saved. However, in fact, the meters allow you to pay only for actually consumed volumes of heat, water or light, and not for the established standards (usually calculated according to the meter footage of the apartment). That is, the owners of housing after installation of the meter may pay less, but this is due only to the tariff policy of the state.

In order to save heat, it is necessary to reduce heat loss through the installation of energy-efficient equipment, insulation of doors and windows, the use of thermostats that allow individual changes in the room temperature. However, if the apartment does not have an individual heat meter, there are no financial reasons for taking such measures from residents.

Valtec heat meter with tachometric flowmeter.

House and apartment heat meters

Heat meters may be about or individual . The management company is engaged in the installation of house counters. The device readings are taken and divided into all registered tenants of the apartment building, are related to the area of the apartment and are entered in receipts. To pay only for what you are consuming, it is worth paying attention to the apartment counters. However, they can be installed only in case of horizontal distribution of the heating system, when each apartment has a separate entrance. In modern houses under construction, this kind of heating system is designed, so the tenants enter the apartments already equipped with heat meters.

If the heating is organized vertically, with the help of risers - as in old houses, you will have to put special devices called heat spreaders , for each radiator of water heating. Heat distributors calculate how much of the general heat consumption is accounted for by a specific heating device due to the difference in the temperature of the radiator and the internal air. Distributors have a number of drawbacks: high error, non-transparent calculation of the amount to pay for residents, as well as the ability to artificially lower the meter's readings. These devices can be considered as a temporary measure for the transition to pokartarny accounting of heat.

Individual heat counting

It is important to take into account that the transfer of consumers to individual heat accounting is carried out only on condition that 50% of all tenants want to install a home meter. Unfortunately, if only one person wants to install a personal heat meter in an entire apartment building, he does not have the right to do so.

The initiator of the transition to the new scheme may be the general meeting of the tenants or the management company. In the first case, the owners of the apartments submit a collective application to the management company to transfer the house to an individual heat meter, in the second, the CM collects the signatures of the tenants who agree with the proposal.

Then the management company orders a reconstruction project for the heating system, which must necessarily pass state expertise, and in some cases, coordination with the heat supply organization, and carries out its alteration on its own or with the help of installation specialists.

Requirements and installation of heat meters

The heat meter must have a certificate of compliance with GOST R 51649-2000 "Heat meters for water heating systems. General technical conditions "and pass the initial verification. If the meter is certified not as a kit, but as a set of measuring instruments, each of them must undergo a separate verification.

The installation of the meter is best entrusted to professionals - proven companies that have all the relevant certificates and licenses, give a guarantee, provide maintenance services and have extensive experience in this field. When receiving the meter, you need to make sure that the meter connection node allows you to disconnect the counter from the system so that it can be carried as a verification.

The principle of the heating system

The modern system of supplying thermal energy to homes is based on the movement of the coolant on heating appliances and at the same time transferring the store of thermal energy to the environment. As the coolant, ordinary water is used, which has undergone special chemical preparation and purification, the purpose of which is to reduce the content of calcium and iron salts in its composition.

The operating principle of a conventional heating radiator is simple: hot water enters its upper part, is distributed in sections and flows downward along them, while cooling down. The cooler the coolant will cool during this movement, the more heat will be transferred to the room. The intensity of the heat release also depends on the difference in the temperatures of the coolant and the heated room.

In other words, for better and more efficient heating, the coolant should be heated as much as possible. It should be remembered that the surface of the radiators must be safe for people and objects nearby, which means that they should not be excessively heated and scorching. Usually, the heaters have a surface temperature of 70-75 degrees Celsius.

But the heating of the room depends on the amount of coolant. It is clear that a glass of tea, heated to 90 degrees Celsius, can not significantly affect the air temperature, even in a small room. At the same time, it is possible to ensure constant heating of radiators only if the coolant is kept in it permanently and maintains its set temperature.

This effect can be achieved only in one way, ensuring a constant circulation of the coolant. For this, the heating system is closed. Then the amount of thermal energy obtained can be calculated from the formula

Q = CM (T1-T2), where

C - heat capacity of coolant

M - its mass

(T1-T2)- the difference between the temperatures of the coolant before entering it and after leaving the heater.

Therefore, to measure the amount of thermal energy received, it is necessary to know the temperature of the coolant and its flow rate, the value of which depends on the pressure of the network water and the cross-sectional area of the supply pipeline.

By this principle, practically all heat energy meters that have instruments for measuring the temperature of the coolant and flowmeters are part of their design.

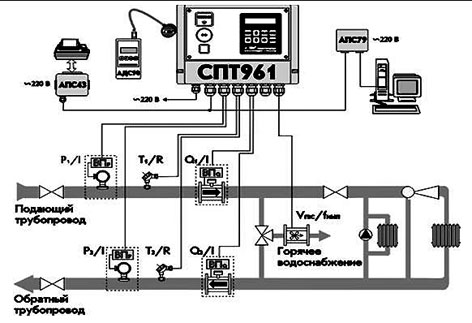

Modern meters of thermal energy work in automatic mode, independently conducting measurements and fixing the received data. The most sophisticated models of these devices can be connected to a computer and transfer data directly to it. As a rule, the counters belong to the sales company and are serviced by it. Below is a traditional scheme for installing a heat meter in a conventional apartment building.

But it should be remembered that in our country there is not one identical thermal input.

Even in a single house with several thermal inputs, the supply pipes can have different diameters, which are not always in line with the actual specifications, as well as various pressure differences in the supply and return pipes. When installing heat meters, you have to make a choice: change the thermal input or choose a suitable heat meter. Of course, most often a decision is made on the selection of a suitable counter.

To do this, consider the device of the heat energy meter in details.

![]() The device of the counter of thermal energy

The device of the counter of thermal energy

All heat meters, regardless of the complexity of their device, consist of sensors and a converting device, which can be conditionally called the "brain" of this device. It can be connected to devices for collecting information: a printer or a display. In appearance, the converting device resembles a calculator with outputs for connecting the respective sensors. It is powered by batteries.

For the residential sector, the simplest conversion device is sufficient to measure the flow of network water and its temperature. In industrial conditions, several heating and water heating circuits can be connected to it simultaneously.

This is the calculator of the amount of heat. He must undergo a state verification of the accuracy of the measurements, and have a control seal.

To measure the temperature of the network water of a simple mercury thermometer is not enough. We need special thermocouples connected to the computing device. Their quality and reliability depend on the accuracy of the measurement, as well as the life of the meter as a whole. Therefore, it is better to use reliable platinum thermocouples for this purpose. These devices also need to pass state verification and have its confirmation.

In the event that the tenants of the house decide to reduce the consumption of thermal energy, they can block the coolant inlet into their radiators. At the same time, the network water, when circulating through a closed heating system, without getting into the heating devices, is unable to give up its thermal energy and leaves in the return pipeline with a higher temperature.

This is fixed by thermocouples. As a result, the temperature drop in the supply and return pipelines decreases, which means that the consumption of thermal energy also decreases.

Measuring the flow of network water

The most common devices for measuring the flow of network water are electromagnetic flowmeters. They have no hydraulic resistance and have practically no effect on the movement of the coolant in the pipeline. They are not afraid of possible water pollution and the quality of the pipes. These devices fix an electromagnetic impulse that changes when a certain amount of water passes through a section of the pipeline on which they are installed.

To account for the flow of water, mechanical flowmeters can also be used, but they are installed directly in the pipe, for which it has to be dismantled and cut. In addition, for mechanical metering devices, a significant pressure drop in the pipelines is needed, and this may not always be available.

Heat meters (heat meters).

Kind time of the day, dear visitors of our site!

Today we will deal with you with such a concept as a heat meter, it's a heat meter, it's a counter for individual heat metering.

Questions that we will pay attention to in this article:

- What is a heat meter?

- Is its installation profitable?

- Types, price, installation and profitability of the heat meter,

- Pros and cons (recommendations).Let's start in order.

Question 1. What is a heat meter?

Any heat meter, regardless of its manufacturer, technical data and prices can be conditionally divided into three parts:

- Thermal energy calculator (heat quantity calculator ) - an electronic unit for processing data and calculating the amount of heat

further under the text - calculator- The flowmeter with the possibility of remote signal transmission - counter for hot water with reed switch, electromagnetic or vortex flow converter, hereinafter - flowmeter

- Temperature sensors - a selected pair of thermoresistance with the same error for installation on the supply and return piping) with sleeves and bosses for mounting, hereinafter - temperature sensors

- Pressure Sensors - in complex heating systems, additional connection of pressure transducers is possible for more accurate

determination of flow.Question 2. How does the heat meter work?

The flowmeter counts the amount of hot water flowing in the pipeline and transmits data to the unit. At the same time, data is taken from the temperature sensors. The data from the flowmeter and the temperature sensors enter the thermal energy calculator, in which the volume of heat consumed is calculated from the parameters of the heat carrier. The calculator translates the data on the consumed energy into kilojoules (kJ) or gigocaloria (gcal), depending on the requirements of the heat supply organization.

Depending on the installation site, all heat meters can be conditionally divided into apartment and industrial.

Apartment heat meters (DN 15mm, DN 20mm.) Are usually monoblock, ie the flowmeter and the calculator are in the same block.

Industrial heat meters consist of three parts, and the number of flow meters and temperature sensors can be very large.Question 3. What are the types of heat meters?

All heat meters according to the principle of the flowmeter are divided into:

- Mechanical heat meters.

As an example: a heat meter CT-10, based on the TSA and VTE.

These are the simplest of the species represented. They are installed in apartments, shops, and utility facilities.

The principle of the heat meter based on the transformation of the translational motion of the flow of water into the rotational motion of the impeller or turbine.

This type of heat meters is the cheapest, but requires the installation of filters and are very sensitive to mechanical impurities.

Available in diameter from 15 to 250 mm.

- Electromagnetic heat meters.As an example: a heat meter based on VKT and PREM.

Well proven at industrial facilities and utilities.

based on the conversion of the amount of liquid to be measured when passing through a magnetic field into an electric current. These heat meters are sensitive to the appearance of impurities in coolants, but the high metrological stability has attracted more and more customers lately.

They are produced in diameter from 20 to 200 mm.- Vortex counters of heat.

As an example: a heat meter based on VKT and VEPS.

These heat meters as well as electromagnetic meters are used at various sites.

The principle of the heat meter It is based on the formation of vortices behind an obstacle in the path of the flow of a liquid. Vortex

Heat meters are less demanding on the length of straight pipe sections before and after the converter.

They are produced in diameter from 20 to 300 mm.- Ultrasonic heat meters.

As an example: heat meters of type PRAMER-510, US-800.

This type of devices is used, mainly, on objects with a diameter of 150mm and higher, because are manufactured up to DN 2000mm.

The principle of the heat meter based on the measurement of the transit time to the receiver signal, which, in turn, depends on the flow velocity of the coolant. Wide success was not obtained due to stable operation only on clean water and, with the existing foreign inclusions (scales, part of scale, sand, etc.) their readings deviate significantly.

Available in diameter from 15 to 2000 mm.Question 4. What is the price of a heat meter?

The financial side of this issue is also no less interesting. Many people think that the heat meter as a loaf of bread - went into the store and bought it,

However, the price of this type of heat metering can be very different.

Let's start with the main - with a diameter.

In apartments and houses, basically, pipes of 15 and 20 mm are used.

Within the limits of heating, the diameters range from 15 to 100 mm.

At industrial facilities - all diameters.

That's what should be based on this.

Heat meter in the apartment costs 5500-6500r.

Industrial meters, installed in the heating frame, can cost from 15000 to 200000r.

The price is affected by the number of converters (1 or 2) and various options such as: NP-4A storage (for data storage), MC52i GSM modem (for data transmission to a single settlement center via GSM networks), additional network unit from the network 220V), the cabinet for installing the calculator (additional), and of course, the type of converter (mechanical, electromagnetic, etc.)

In view of this, the final price of the heat meter is calculated individually and can vary greatly even on the same diameter.Question 5. Economic sense of installation and operation of a heat meter?

This question implies two questions: Installation of a heat meter and profitability of a heat meter.

The most interesting and often asked question. Let's figure it out in more detail.

So, the simplest case is the installation of a heat meter in an apartment.

Who installs?

What to consider when buying?

How much is?

Is there any financial benefit?About the cost of the device itself is already mentioned above, as for the cost of installation, adjustment - it can be significantly more expensive than the cost

equipment (as is often the case in construction). The cost of expenses not related to the cost of equipment can vary significantly, depending on the requirements of the heat supply organization and the location of the device.

Their calculation is quite simple. Take with you a passport and documents for an apartment, come with these documents to an organization that

pay for heat and write an application for the installation of a heat meter.

Based on your application, they are required to write to you the technical conditions for the installation and operation of the equipment or to give

motivated refusal.

There are two options: you are denied the possibility of installing heat meters or allow installation. In case of impossibility of installation

heat meters or the heat seller's unwillingness to install a heat meter (this is a very common practice for many management companies

is the Russian reality and it does not depend on us !!!) you will receive a valid written response and here it is up to you to decide,

fight with them or wave at the installation by hand.If the heating company is authorized to install the heat meter, you will receive in writing the technical conditions in which

contain the parameters of the meter, the order and place of its installation, the procedure for taking readings and the calculation procedure with the seller of heat.But, how to install the heat meter correctly?

And how many do they need in the apartment?To install a heat meter it is necessary for each heating riser entering the apartment, ie, if you have 3 inputs - you need to put 3 heat meters.

This type of wiring is called vertical pipe routing and we do not recommend the installation of heat meters because of the high financial costs.

This wiring was used before, in houses built during the existence of the USSR, and now it finds a mass use in new buildings.

In some new homes (though not all), building companies use horizontal piping with individual heating input to each apartment, which gives a cost-effective opportunity to install a heat meter. It should also be noted that the installation should be carried out by a specialized organization that has a license for the design, installation and maintenance of heat metering units.

And do not forget about verification of the device! After 4 years, the heat meter must be calibrated in a specialized organization, and in subsequent years annually.

This very costly item of expenditure and we advise you to take it into account in your financial calculations.

And again it is worth repeating - you can not independently install a heat meter without the knowledge of the "master of heat", those. that organization,

which sells you heat (heating systems, CC, TSZH) If this organization does not give "good" for the installation - then you do not see the heat meter. For this reason, they are very much disputing now, but the answer to the question: "Can I supply a heat meter?" you can find out only there.Proceeding from this, it is possible to sum up - the installation of a heat meter is cost-effective in the horizontal distribution of pipes, with large heat bills and with "loyalty" to the heat supply organization. In all other cases, the installation will not pay off itself and will bring you a lot of headache and not pleasant emotions.

And finally, if all of this does not bother you, go ahead!Consider another case - the installation of a heat meter in the heating frame.

This is usually the most profitable way to save on utility services. Usually, one heat meter is installed on the heating frame that serves 40 to 100 apartments.

Its cost will be in the range of 20000-100000r + installation. Dividing this by the number of apartments, we get a completely sane amount, which can

afford many.

In this case, you will pass the same tests during installation, but these ordeals can be more than paid off during operation.And, finally, the case number is a 3- heat meter for the production, the plant, for industrial needs in the boiler room.

In this case, the installation of a heat meter can be carried out only for the project and for calculating the heat load.

The question of the economic meaning of this operation is not considered - in view of the very large spread of costs and economy.Question 6. And what in the end (pluses and minuses, recommendations)?

So, what to note in the totals?

The disadvantages of the heat meter include its high cost, the complexity of selection and operation, and also the low prevalence in our country.

The advantages of heat meters include its main purpose - saving on payments for heat!

In general, I would like to recommend in homes and apartments to put good windows and entrance doors, to isolate pipelines and other places of heat leakage and

You can save a lot on payments.

Dear readers!

Heat meters for heating are installed in apartments in order to save money for utilities.

After all, not always in the room is warm enough, and receipts come for the full use of thermal energy. Despite the savings, the installation process is quite expensive, but after a certain time the whole amount pays off with interest.

Heat meters can be of 2 types:

- Devices installed on a common communal pipe.

- Devices mounted on a private pipeline in a separate apartment.

After installation of devices, payment for utilities is calculated on the basis of the received indications. Select an individual heat meter for heating can be any model. At purchase it is necessary to consider quality of the heat-carrier in the pipeline.

Types of counters for installation

Today, heat meters can easily be found on the market.

There are several types of installation:

- The work of ultrasonic devices is based on the time of passage of the signal from the source to the receiver. The principle of operation depends on the velocity of the coolant passing through the pipes. Ultrasonic counters are designed for clean coolants. If any impurities or dirt are observed in the liquid, the device will show with great error.

- Electromagnetic installations work by the appearance of an electric current during the passage of the coolant through a magnetic field. Devices differ in significant accuracy in the indications, but if the coolant contains impurities, deviations in the data will be observed. The meter may malfunction due to oxidation of contacts and wires.

- The principle of operation of vortex devices is based on the appearance of obstacles before the flow of the coolant. This type of meters is quite convenient, they can be installed on both horizontal and vertical pipes. If there are impurities in the coolant, there will be no malfunctions, only the presence of a large amount of air will adversely affect the readings of the device.

- Mechanical models are among the simplest. The work is based on the translational motion of the coolant, which is converted into rotational in the accounting mechanism. If too hard water is used, this kind of device will not work. A malfunction may occur due to a constant pressure difference. The functionality of the device can be affected by the presence of impurities in the liquid. They will clog the passage, as a result the device will fail.

Heat meter for heating in the apartment must be selected carefully, you should take into account all the factors that affect its operation. It is best to entrust the choice to specialists who know how to use such devices.

How to choose a heat meter?

The heat meter for the apartment must be selected based on certain criteria:

- Uncertainty of measurement of thermal energy. The modern heat meter has an error of 4% with a temperature difference in the water pipe of 20 ° C. This is considered the norm according to established standards. Recently, there have been improved instruments that show more accurate measurements.

- The error in measuring the mass. Thermal counters for heating have an error in measuring the mass of about 2%, but this is considered the norm. The meters measure the mass difference of the liquids. The smaller the value of the indicator, the more accurate the measurement data will be. Manufacturers are developing advanced devices that have an error of only 1%.

- Values of flow changes. The heat meters do not always correctly measure the heat energy. This depends on the fact that the fluid flow rate can vary. For example, if you switch from winter time to a summer coolant, it reduces the head pressure, but the device can not accurately capture the transition, as a result, the readings are not completely correct. Therefore, it is necessary to select devices that have an error of not more than 2%.

- Loss of pressure. Water volume converters, which are installed in pipelines, have a hydraulic resistance, because of this, a difference in pressure is created. Due to the fact that there is sometimes a slight pressure of the carrier in the pipeline, the readings may have a large error. To make the data as accurate as possible, it is better to choose electromagnetic or ultrasonic devices that respond to the slightest change in pressure.

- Temperature and pressure recording. The heat meter for the apartment should record the temperature and pressure of the coolant every hour. This allows you to get accurate readings. All types of devices meet these requirements.

- Availability of a diagnostic system. Almost all modern devices have a self-diagnostic system that allows monitoring changes occurring in the operation of the thermal system. All data is recorded in the archive, in which you can see what caused the problem. Failures can be both in the operation of the device itself and in the heat supply pipeline system.

- Presence of direct pipeline sections. The heat meter will show more accurate measurements if installed on a sufficiently long straight section of the pipeline. It is this condition that makes it possible to obtain the most correct indications. This requirement applies to virtually all devices. Ultrasound devices are extremely sensitive to this parameter, but in the basement it is not always possible to fulfill this condition.

Installation and operating principle

The installation of a heat meter always requires preparatory work, which includes:

- Creating a project for installing the device.

- Harmonization of the developed device of the heat meter with utilities.

- If the special services approve the installation of the device, then you can install the device in the apartment.

- Once the heat meters have been installed, registration in the utility service is required so that the appliance can be used.

After all the procedures are performed, you must call a specialist to perform the following works:

- Reconcile all documentation.

- Mount the selected device.

- Officially register the device.

- To hand over the device for use, to report it to all controlling bodies. Any heating meter must have a passport and a certificate. These documents specify the service life of the device, as well as the time when device checks are to be carried out.

Heat meters have 2 sensors, one of which shows the flow, and the other - the temperature of the coolant. The first sensor calculates how much heat is consumed and the second measures the temperature of the coolant. The main part of any device is a heat calculator. The readings are equal to the product of the consumed heat carrier at its temperature. It is for such a value to pay utility bills.

Once every 4 years, any heat meter should be tested.

It is conducted by a specialist, all indications are recorded in a special passport. Each mark of the inspector indicates the serviceability of the device.

Installation of a house heating meter is decided at the meeting of the tenants. This device allows you to determine the heat energy consumed throughout the house. It has certain advantages over individual devices:

- low cost;

- calculation is carried out by the number of residents;

- independent installation is possible.

Installation of heat meters for the whole house is made by the responsible person, all expenses are divided by the number of tenants. Such a device will quickly justify all the funds spent on its purchase and installation.