Antipyretics for children are prescribed by a pediatrician. But there are situations of emergency care for fever, when the child needs to give the medicine immediately. Then the parents take responsibility and apply antipyretic drugs. What is allowed to give to infants? How can you bring down the temperature in older children? Which medications are the safest?

The ease of converting AC voltage made it the most widely used in power supply. In the field of designing electric motors, another advantage of alternating current has been discovered: the possibility of creating a rotating magnetic field without additional transformations or with their minimum amount.

Therefore, even in spite of certain losses due to the reactive (inductive) resistance of the windings, the simplicity of creating alternating current electric motors contributed to the victory over the DC power supply in the early 20th century.

In principle, AC motors can be divided into two groups:

Asynchronous

In them, the rotation of the rotor differs in speed from the rotation of the magnetic field, so that they can operate at different speeds. This type of AC electric motors is the most common in our time. Synchronous

These engines have a rigid relationship between the rotor speed and the rotation speed of the magnetic field. They are more difficult to manufacture and less flexible in application (changing the speed at a fixed frequency of the supply network is possible only by changing the number of poles of the stator).

They find application only at high capacities of several hundred kilowatts, where their greater efficiency in comparison with asynchronous electric motors significantly reduces heat losses.

AC INDUCTION ELECTRIC MOTOR

The most common type of induction motor is an electric motor with a squirrel cage rotor type, where a set of conductive rods is laid in the inclined grooves of the rotor, from the ends connected by rings.

The history of this type of electric motors has more than a hundred years, when it was observed that a conductive object placed in the gap of the core of an AC electromagnet tends to escape from it due to the emergence of an EMF induction with a counter-directed vector.

Thus, the squirrel-cage induction motor does not have any mechanical contacting components other than the rotor bearing bearings, which provides this type of motor not only with a low price, but with the highest durability. Due to this, electric motors of this type became the most widespread in modern industry.

However, they have certain drawbacks, which must be taken into account when designing asynchronous electric motors of this type:

High inrush current - since at the moment when the asynchronous brushless electric motor is turned on, the reactive resistance of the stator winding is still not affected by the magnetic field created by the rotor, there is a strong current surge several times greater than the rated current of consumption.

This feature of the operation of this type of engines must be laid in all designed power supply in order to avoid overloads, especially when connecting asynchronous electric motors to mobile generators with limited power.

Low starting torque - electric motors with a short-circuited winding have a pronounced dependence of the torque on the revolutions, so their inclusion under load is highly undesirable: the time to the nominal mode and the starting currents increase significantly, the stator winding is overloaded.

For example, this happens when deep pumps are switched on - in the electrical circuits of their power supply, a five-seven-fold current reserve must be taken into account.

Impossibility of direct start in single-phase current circuits - for the rotor to start to rotate, it is necessary to start the jog or introduce additional phase windings, shifted in phase relative to each other.

To start an asynchronous alternating current motor in a single-phase network, either manually switched starting winding is disconnected after the rotor is untwisted, or the second winding included through the phase-rotational element (most often a capacitor of the required capacity).

No possibility of obtaining high speed - Although the rotation of the rotor is not synchronized with the rotational speed of the stator magnetic field, it can not surpass it, so in the 50 Hz network, the maximum rotations for an induction motor with a squirrel cage rotor are no more than 3000 rpm.

Increasing the speed of an induction motor requires the use of a frequency converter (inverter), which makes such a system more expensive than a collector motor. In addition, as the frequency increases, the reactive losses increase.

The difficulty of organizing a reverse - This requires a complete engine shutdown and phase recomposition, in a single-phase version - phase displacement in the starting or second phase winding.

The most convenient use of an asynchronous electric motor in an industrial three-phase network , since the creation of a rotating magnetic field is carried out by the phase windings themselves without additional devices.

In fact, a chain consisting of a three-phase generator and an electric motor can be considered as an example of an electric transmission: the generator drive creates a rotating magnetic field in it, which is converted into oscillations of the electric current, which in turn drives the rotation of the magnetic field in the motor.

In addition, it is with three-phase power supply that asynchronous motors have the highest efficiency, since in a single-phase network the magnetic field created by the stator can in fact be decomposed into two antiphase fields, which increases the useless losses on the core saturation. Therefore, powerful single-phase electric motors are usually performed according to a collector circuit.

ELECTRIC MOTOR COLLECTOR

In electric motors of this type, the magnetic field of the rotor is created by phase windings connected to the collector. Actually, the AC motor collector is different from the DC motor only in that the reactance of the windings is included in its calculation.

In some cases, even generic collector motors are created, where the stator winding has a branch from the incomplete part to be connected to the AC mains, and the current source can be connected to the full winding length.

The advantages of this type of engine are obvious:

Ability to work at high speed allows creating collector electric motors with a speed of up to several tens of thousands of revolutions per minute, familiar to all by electric drills.

No need for additional triggers in contrast to the motors with a squirrel-cage rotor.

High starting torque, which accelerates the output to the operating mode, including under load. Moreover, the torque of the collector motor is inversely proportional to the revolutions and when the load increases, it avoids the drawdown of the rotational speed.

Ease of speed control - since they depend on the supply voltage, it is sufficient to have the simplest triac voltage regulator to adjust the rotational speed within the widest limits. If the regulator fails, the collector motor can be connected directly to the network.

Less inertia of the rotor - it can be made much more compact than with a short circuit, so that the collector motor itself becomes noticeably smaller.

Also, the collector motor can be elementary reversed, which is especially important when creating a variety of power tools and a number of machines.

For these reasons, collector motors are widely distributed in all single-phase consumers, where flexible speed control is necessary: in manual electric tools, vacuum cleaners, kitchen appliances and so on. However, a number of design features determine the specific operation of the collector motor:

Collector motors require regular replacement of brushes that wear out with time. The collector itself also wears, while the motor with a squirrel-cage rotor, as already mentioned above, under the condition of infrequent bearing replacement is practically eternal.

The inevitable sparking between the collector and brushes (the reason for the appearance of a familiar odor of ozone during the operation of the collector motor) not only additionally reduces the resource, but also requires increased safety measures during operation because of the likelihood of ignition of combustible gases or dust.

© 2012-2017 г. All rights reserved.

All materials on this site are of an informational nature only and can not be used as guidelines and normative documents

Single-phase electric motor 220V is a separate mechanism, which is widely used for installation in a variety of devices. It can be used for domestic and industrial purposes. Power electric motor is carried out from an ordinary outlet, where there is necessarily a power of at least 220 volts. It should pay attention to the frequency of 60 hertz.

In practice, it has been proven that a single-phase 220 V motor is sold together with devices that help convert the energy of an electric field, and also accumulate the necessary charge with a capacitor. Modern models, which are manufactured using innovative technologies, 220V electric motors are additionally equipped with equipment to illuminate the workplace of the device. This applies to internal and external parts.

It is important to remember that the capacitance of the capacitor must be stored in compliance with all basic requirements. The best option is the place where the air temperature remains unchanged and is not subject to any fluctuations. In the room, the temperature regime should not be lowered to a minus value.

During the use of the engine, experts recommend that from time to time to measure the capacitance of the capacitor.

Asynchronous motors are now widely used for various production processes. For different drives this model of electric motor is used. Single-phase asynchronous structures help to drive woodworking machines, pumps, compressors, industrial ventilation devices, conveyors, lifts and many other equipment.

Asynchronous motors are now widely used for various production processes. For different drives this model of electric motor is used. Single-phase asynchronous structures help to drive woodworking machines, pumps, compressors, industrial ventilation devices, conveyors, lifts and many other equipment.

The electric motor is also used for driving small-scale mechanization. This includes the feed choppers and concrete mixers. Buy these structures only from trusted suppliers. Before acquiring it is desirable to check the certificates of conformity and the manufacturer's warranty.

Suppliers must provide their customers service of the electric motor in the event of a breakdown or failure. This is one of the main components that is completed during the assembly of the pump unit.

Existing series of electric motors

Today, industrial enterprises produce the following series of single-phase electric motor 220V:

Absolutely all engines are subdivided on a design, by the method of installation, as well as the degree of protection. This allows you to protect the structure from moisture or mechanical particles.

Features of A series electric motors

Electric single-phase motors of series A are unified asynchronous designs. They are closed from external influences by means of a short-circuited rotor.

The motor structure has the following execution groups:

The cost of a single-phase 220V motor depends on the series.

What are the different types of engines?

Single-phase motors are designed for manning electric drives, having a domestic and industrial purpose. Such designs are manufactured in accordance with state standards.

Areas of use. Asynchronous motors of low power (15 - 600 W) are used in automatic devices and electrical appliances to drive fans, pumps and other equipment that does not require speed control. In electrical appliances and automatic devices, single-phase micromotors are usually used, since these devices and devices are usually powered by a single-phase alternating current network.

The principle of operation and the device of a single-phase motor. The stator winding of a single-phase motor (Figure 4.60, a)is located in grooves that occupy about two-thirds of the circumference of the stator, which corresponds to a pair of poles. As a result,

(see Chapter 3), the distribution of MDS and induction in the air gap is close to sinusoidal. As the alternating current passes through the winding, the MDS pulsates with the network frequency in time. Induction at an arbitrary point of the air gap

In x = In m sinωtcos (πx / τ).

Thus, in a single-phase motor, the stator winding creates a stationary flow that varies with time, rather than a circular rotating flow, as in three-phase motors with symmetrical power.

To simplify the analysis of the properties of a single-phase motor, we represent (4.99) in the form

At x = 0.5V, sin (ωt - πx / τ) + 0.5V sin (ωt + πx / τ),.

that is, we replace the fixed pulsating flow by the sum of identical circular fields rotating in opposite directions and having the same rotation frequencies: n 1pr = n 1ob = n 1 . Since the properties of an asynchronous motor with a rotating circular field are considered in detail in § 4.7 - 4.12, an analysis of the properties of a single-phase motor can be reduced to considering the joint action of each of the rotating fields. In other words, a single-phase motor can be represented in the form of two identical motors, the rotors of which are rigidly connected (Figure 4.60, b), with the opposite direction of rotation of the magnetic fields and the moments created by them M pr and M arr. A field whose direction of rotation coincides with the direction of rotation of the rotor is called direct; field of the reverse direction - inverse or inverse.

Assume that the direction of rotation of the rotors coincides with the direction of one of the rotating fields, for example with n pr. Then the sliding of the rotor relative to the flow F etc

s pr = (n 1pr - n 2) / n 1pr = (n 1 - n 2) / n 1 = 1 - n 2 / n 1..

Slip of the rotor relative to the flow

s ob = (n 1obr + n 2) / n 1obr = (n 1 + n 2) / n 1 = 1 + n 2 / n 1..

From (4.100) and (4.101) it follows that

s o6p = 1 + n 2 / n 1 = 2 - s pr..

Electromagnetic moments M pr and M obr, formed by direct and reverse fields, are directed in opposite directions, and the resultant moment of a single-phase motor M The cut is equal to the difference of the moments at the same rotor speed.

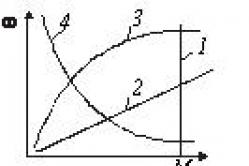

In Fig. 4.61 shows the dependence M = f (s) for a single-phase motor. Considering the drawing, we can draw the following conclusions:

a) the single-phase motor does not have a starting torque; it rotates in the direction in which it is driven by an external force; b) the frequency of rotation of a single-phase motor at idle is less than that of a three-phase motor, because of the braking torque produced by the return field;

c) the performance of a single-phase engine is worse than that of a three-phase motor; it has increased slip at nominal load, less efficiency, less overload capacity, which is also explained by the presence of an inverse field;

d) the power of a single-phase motor is approximately 2/3 of the power of a three-phase motor of the same size, since in a single-phase motor the working winding takes only 2/3 of the stator slots. Fill all stator grooves

since the winding coefficient is small, the copper consumption increases by about 1.5 times, while the power increases only by 12%.

Starting devices. To obtain the starting torque, single-phase motors have a starting winding shifted by 90 electric degrees relative to the main working winding. For the starting period, the starting winding is connected to the network via phase-shifting elements - capacitance or active resistance. After the end of the acceleration of the engine, the starting winding is switched off, while the engine continues to operate as a single-phase winding. Since the starting winding only works for a short time, it is made of a wire with a smaller cross-section than the working one, and is packed into a smaller number of grooves.

Let us consider in detail the start-up process when using capacitance C as a phase-shifting element (Fig. 4.62, a). On the starting winding P voltage

Ú

In = Ú

1 - Ú

C = Ú

1 +jÍ 1 P X C, i.e., it is phase-shifted relative to the mains voltage U 1, applied to the working winding R. Consequently, the current vectors in the working I 1p and starting I In windings are shifted in phase by some angle. Choosing the capacitance of a phase-shifting capacitor in a certain way, it is possible to obtain a start-up mode close to a symmetric one (Fig. 4.62, b), ie, to obtain a circular rotating field. In Fig. 4.62, in the shown dependences M = f (s) for the engine with the (1) turned on and the starting winding off (curve 2). Start the engine is carried out on a part ab Characteristics 1; at the point bthe starting winding is switched off, and in the future the engine operates on a part cO characteristics 2.

Since the inclusion of the second winding significantly improves the mechanical characteristics of the engine, in some cases single-phase motors are used in which the windings A and B

are included all the time (Figure 4.63, a). Such engines are called capacitor ones.

Both windings of capacitor motors, as a rule, occupy the same number of grooves and have the same power. When the capacitor motor is started to increase the starting torque, it is advisable to have an increased capacitance C p + C n. After accelerating the motor according to characteristic 2 (Figure 4.63, b) and decreasing the current, some of the capacitors Cn are disconnected so that at rated operation (when the motor current becomes smaller, than at start-up) to increase capacitive resistance and to provide work of the engine in the conditions close to work at a circular rotating field. In this case, the motor operates on characteristic 1.

The capacitor motor has a high cos φ. Disadvantages of it are the relatively large mass and dimensions of the capacitor, as well as the appearance of a non-sinusoidal current with distortions of the supply voltage, which in some cases leads to harmful effects on the communication line.

Under light starting conditions (a small loading torque in the starting period), start-up motors R (Figure 4.64, a). The presence of an active resistance in the starting winding circuit provides a smaller phase shift φ n between the voltage and current in this winding (Figure 4.64, b) than the phase shift φ p in the working winding. In this connection, the currents in the working and starting windings turn out to be phase-shifted by an angle φ p - φ n and form an asymmetric (elliptical) rotating field, due to which the starting torque arises. Motors with start-up resistance are reliable in operation in are produced serially. The starting resistance is built into the motor housing and cooled with the same air that cools the entire engine.

Single-phase micromotors with shielded poles. In these engines, the stator winding connected to the grid is usually concentrated and strengthened at the clearly expressed poles (Figure 4.65, a), the sheets of which are stamped together with the stator. At each pole, one of the tips is covered by an auxiliary winding consisting of one or more short-circuited turns, which shield from 1/5 to 1/2 pole poles. The rotor of the engine is a short-circuited conventional type.

The magnetic flux of the machine created by the stator winding (pole current) can be represented as the sum of two components (Fig. 4.65, b), where n is the flux passing through a part of the pole not covered by a short-circuited th coil; Ф n2 is the flux passing through a part of the pole, screened by a short-circuited turn.

The fluxes Ф п1 and Ф n2 pass through different parts of the pole piece, that is, they are displaced in space by the angle β. In addition, they are phase-shifted relative to the MDS F n stator windings at different angles - γ 1 and γ 2. This is explained by the fact that each pole of the described engine can be considered in the first approximation as a transformer, the primary winding of which is the stator winding, and the secondary winding is a short-circuited coil. The flow of the stator winding induces a short circuit of the emf E to (Figure 4.65, c), as a result of which there is a current I to and MDS F to, developing with the MDS F n stator windings. Reactive current component I k decreases the flux Φ n2, while the active one shifts it in phase relative to the MDS F etc. Since the flux Ф п1 does not include a short-circuited turn, the angle γ 1 has a relatively small value (4-9 °) - about the same as the phase angle between the transformer's current and the primary winding's MDS in idle mode. The angle γ 2 is much larger (about 45 °), i.e., as in a transformer with a secondary winding, short-circuited (for example, in a current measuring transformer). This is explained by the fact that the power losses on which the angle γ 2 depends are determined not only by the magnetic losses of power in the steel, but also by the electric losses in the short-circuited coil.

Fig. 4.65. Design diagrams of a single-phase motor with shielded poles and its

vector diagram:

1

- stator; 2 -

stator winding; 3 -

squirt

coil; 4 -

rotor; 5

- pole

The fluxes Ф п1 and Ф n2, displaced in space by an angle β and shifted in phase in time by the angle γ = γ 2 - γ 1, form an elliptic rotating magnetic field (see Chapter 3), which compensates the rotational moment acting on the rotor motor in the direction from the first pole piece not covered by the short-circuited turn to the second tip (in accordance with the alternation of the maxima of the "phase" flows).

To increase the starting torque of the engine under consideration, by approaching its rotating field to a circular one, various methods are used: between the pole pieces of adjacent poles, magnetic shunts that enhance the magnetic coupling between the main winding and the shorted turn and improve the shape of the magnetic field in the air gap; increase the air gap under the tip not covered by a short-circuited turn; use two or more short-circuited turns on one tip with different angles of coverage. There are also engines without short-circuited turns at the poles, but with an asymmetrical magnetic system: various configurations of the individual parts of the pole and different air gaps. Such engines have a smaller starting torque than motors with shielded poles, but their efficiency is higher, since they have no power losses in short-circuited turns.

The considered designs of motors with shielded poles are non-reversible. To implement the reverse in such engines instead of short-circuited coils are used coils B1, B2, B3and AT 4(Figure 4.65, at), each of which spans half the pole. Shorting a couple of coils IN 1and AT 4or AT 2and AT 3, it is possible to shield one or the other half of the pole and thus change the direction of rotation of the magnetic field and the rotor.

The motor with shielded poles has a number of significant drawbacks: relatively large overall dimensions and mass; low cos φ ≈ 0,4 ÷ 0,6; low efficiency η = 0,25 ÷ 0,4 because of large losses in the short-circuited coil; small starting torque, etc. Advantages of the engine are the simplicity of the design and therefore high reliability in operation. Due to the absence of teeth on the stator, the engine noise is insignificant, so it is often used in devices for reproducing music and speech.

3-7. DEVICE OF ASYNCHRONOUS SINGLE-PHASE ELECTRIC MOTORS

In Fig. 3-16 shows the device of an asynchronous single-phase AOLB-type motor with built-in starting resistor. The stator of the electric motor is assembled from the stamped sheets of electrical steel 15, pressed and poured into an aluminum shell (stator housing) with double walls 13. Between the walls, channels for air cooling the stator surface are formed. On the sharpening of the stator housing are put two covers 2 and 17, cast from an aluminum alloy.

The front cover 17 is fitted with a stamped cap 18 with holes in the end face. Through these openings, when the rotor rotates, the fan 19, mounted on the end of the rotor shaft, takes the air. The fan is cast from an aluminum alloy and fixed to the shaft with a screw.

In the stator sheets, 24 grooves of the pear-shaped form are stamped. Of these, 16 slots are occupied to the wires of the working winding, and 8 slots are to the wires of the starting winding. The lead ends of the working and starting windings are led to the contact screws 4 located in the terminal box 11. The rotor core is assembled from the electrical steel sheets 12 and pressed onto the corrugated surface of the middle part of the shaft 1. An aluminum winding 14 with closing rings and fan blades is embedded in the rotor grooves. The purpose of the fan is to reject the heated air to the cooled outer walls of the housing.

The centrifugal switch of the starting winding is mounted on the rotor. It consists of two levers 7 with counterweights 9, sitting on the axles 8, which are pressed in four fan blades. The levers are pressed with pins 6 onto the plastic sleeve 5, freely seated on the shaft. When the rotor is accelerated, when the frequency of its rotation approaches the nominal, the counterweights diverge under the action of the centrifugal force, turning the levers around the axes.

In this case, the sleeve 5 moves to the right, compressing the spring 10, and releases the spring contact 4, which closes the starting winding circuit. This contact with the fixed rotor is closed by the end of the sleeve with the fixed contact 3.

The movable and fixed contacts are fixed on the insulation board to the rear cover of the electric motor 2. A thermal relay is fixed on it, which disconnects the electric motor from the network when it overheats. Stand 16 with four studs serves to mount the motor.

The circuit for switching on the electric motor is shown in Fig. 3-17.

The supply voltage is supplied to the terminals C 1 and C 2. From these terminals, the voltage is applied to the working winding through the contacts of the thermal relay PT, consisting of a winding, a bimetallic plate and contacts. When the motor is heated above the permissible plate, the contacts bend and open. If there is a short circuit through the winding of the thermal relay, a large current will flow, the plate will quickly heat up and open the contacts. In this case, the working C and starting P windings will be de-energized, since both are fed through a thermal relay. Thus, the thermal relay protects the motor from both overload and short circuits.

The starting winding is fed from the terminals C 1 and C 2 through the C 2 -P 1 jumper, the contacts of the centrifugal switch VC, the bridge VC-RT, the contacts of the thermal relay PT. When the motor starts, when the rotor reaches a speed of 70-80% of the rated speed, the contacts of the centrifugal breaker will open and the starting winding will be disconnected from the mains. When the electric motor is turned on, when the rotor speed decreases, the contacts of the centrifugal switch again close and the starting winding will be ready for the next start.

In Fig. Figure 3-18 shows the design of an asynchronous electric motor of the ABE type. These motors are connected to a network with a permanently switched auxiliary winding whose circuit is connected in series with a capacitor (Figures 3-9). Electric motors of the ABE type do not have a rigid body and are therefore called embedded. With the drive mechanism, the motors are fastened with a flange or bracket.

The housing of the electric motor is a package of the stator core 1, which is assembled from sheets of electrical steel 0.5 mm thick. The package is pressed and pressurized with an aluminum alloy. At the ends of the stator there are pressure rings 5 and four aluminum rods pulling them together. The coils 6 of the working and auxiliary winding are embedded in the stator grooves. On the pressure rings 5, the bearing shields 4 and 7. Through the rubber sleeve 9 in the bearing shield, the ends of the windings 8 are brought out for their adventure to the network. Bearing shields are tightened by four studs.

The rotor of the electric motor is assembled from sheets of electrical steel and is covered with aluminum 2. Along with the winding of the rotor, the fan wings are molded for cooling the electric motor. The rotor rotates in two ball bearings 3.

Electric motors have alphanumeric and numeric type designations, for example the electric motor ABE 041-2 is deciphered as follows: A - asynchronous, В - embedded, E - single-phase,

4 - number of the envelope, 1 - serial number of the length of the stator core and the number 2 through the dash - the number of poles.

3-8. SYNCHRONOUS SINGLE-PHASE ELECTRIC MOTORS

In some cases, electric motors are required whose rotation speed must be strictly constant regardless of the load. As such, synchronous motors are used, in which the rotational speed of the rotor is always equal to the frequency of rotation of the magnetic field and is determined from (3-2). There are many types of synchronous motors for both a three-phase and a single-phase current. Here we consider only two of the simplest types of single-phase synchronous motors: reactive and capacitor reactive.

In Fig. Figure 3-19 shows a schematic diagram of the simplest single-phase reactive motor known in the art, called the La Cura wheel. Stator 1 and rotor 2 are assembled from extruded sheets of electrical steel. A coil, powered from a single-phase alternating-current network, is wound up on the stator, creating a pulsating magnetic field. The name of the jet engine is because the rotor rotates due to the reactions of two forces of magnetic attraction.

With a pulsating field, the motor has no starting torque and must be untwisted by hand. The magnetic forces acting on the teeth of the rotor always tend to place it against the poles of the stator, since in this position the resistance to the magnetic flux will be minimal. However, the rotor, by inertia, passes this position during the time when the pulsating field decreases. With the next increase in the magnetic field, the magnetic forces act on the other tooth of the rotor, and its rotation will continue. For the stability of the stroke, the rotor of the reactive motor must have a large inertia.

Reactive motors operate stably only at a low speed of about 100-200 rpm. Their power usually does not exceed 10-15 watts. The frequency of the rotor is determined by the frequency of the supply network f and the number of teeth of the rotor Z. Since in one half-cycle of the change in the magnetic flux the rotor rotates by 1 / Z of the revolution, in 1 minute, containing 60 2 f half-cycles, it will turn by 60 2 f / Z revolutions . At an AC frequency of 50 Hz, the rotor speed is:

![]()

To increase the torque, increase the number of teeth on the stator. The greatest effect can be achieved by making as many teeth on the stator as on the rotor. In this case, the magnetic attraction will act simultaneously not on a pair of teeth, but on all the teeth of the rotor, and the torque will increase significantly. In such motors, the stator winding consists of small coils that are wound around the stator rim in between the teeth. In electric recorders of old types, an electric motor with 77 teeth on the stator and on the rotor was used, which ensured a disk rotation speed of 78 rpm. The rotor was one with the disc, on which the plate was placed. To start the electric motor it was necessary to push the disk with your finger.

The stator of the synchronous capacitor jet motor is no different from the stator of the capacitor asynchronous electric motor. The rotor of the electric motor can be made from the rotor of an asynchronous electric motor, by profiling in it grooves with respect to the number of poles (Figures 3-20). At the same time, the rods of the squirrel cage are partially cut off. With the manufacture of such electric motors with rotor sheets stamped with pole protrusions, some of the squirrel cage rods play the role of a starting winding. The rotor starts to rotate in the same way as the rotor of an asynchronous electric motor, then it retracts into synchronism with the magnetic field and then rotates with a synchronous frequency.

The quality of the operation of the capacitor motor depends strongly on the operating mode in which the electric motor has a circular rotating field. The ellipticity of the field in synchronous mode leads to an increase in noise, vibrations and disruption of the uniformity of rotation. If a circular rotating field occurs in an asynchronous mode, the motor has a good starting torque, but small moments of entry and exit from synchronism. When the circular field is shifted toward higher frequencies, the starting torque decreases, and the entry and exit times of the synchronism increase. The greatest moments of entry and exit from synchronism are obtained in the case when the circular rotating field takes place in synchronous mode. In this case, however, the starting torque is greatly reduced. In order to increase it, the resistance of the short-circuited winding of the rotor is usually somewhat increased.

A disadvantage of some types of capacitor reactive motors is the sticking of the rotor, which consists in the fact that during start-up the rotor does not rotate but stops in any position.

Typically, the sticking of the rotor is manifested in motors with an unsuccessful relationship between the dimensions of the depressions and the pole projections. The greatest reactive moment with a small power consumed by the electric motor is obtained when the ratio of the pole arc b n to the pole division t is about 0.5-0.6, and the depth of the troughs h is 9-10 times larger than the air gap between the pole projections and the stator.

A positive property of capacitor reactive motors is a high power factor, which is significantly higher than that of three-phase electric motors, and sometimes reaches 0.9-0.95. This is because the inductance of the capacitor motor is largely compensated by the capacitance of the capacitor.

Synchronous jet motors are the most common synchronous motors due to the simplicity of construction, low cost and the absence of sliding contacts. They found application in the schemes of synchronous communication, in installations of sound cinema, sound recording and television.

3-9. USE OF THREE-PHASE ASYNCHRONOUS ELECTRIC MOTORS AS A SINGLE-PHASE

In practice, there are cases where a three-phase electric motor must be connected to a single-phase network. Previously it was believed that this requires rewinding the stator of the electric motor. At present, many schemes of switching three-phase electric motors into a single-phase network have been developed and tested in practice without any changes in the stator windings.

Capacitors are used as starting elements.

The conclusions of the stator winding of a three-phase electric motor have the following designations: C1 - the beginning of the first phase; C2 is the beginning of the second phase; СЗ-beginning of the third phase; C4 - the end of the first phase; C5 - the end of the second phase; C6 is the end of the third phase. These designations are stamped on metal tags on the lead wires of the winding.

The winding of a three-phase electric motor can be connected to a star (Figure 3-21, a) or to a triangle (Figure 3-21, b). When connecting to a star the beginnings or ends of all three phases are connected to one point, and the remaining three terminals are connected to a three-phase network. When connecting in a triangle, connect the end of the first phase with the beginning of the second, the end of the second with the beginning of the third, and the end of the third with the beginning of the first. From the connection points take the conclusions for connecting the motor to the three-phase network.

The three-phase system distinguishes between phase and linear voltages and currents. When joining a star between them, the following relationships hold:

when joining in a triangle

Most of the three-phase electric motors are produced for two line voltages, for example, 127/220 V or 220/380 V. With a lower mains voltage, the winding is connected to a triangle, and at a higher voltage, to a star. At such electric motors on a board: all six lead-out conductors of a winding deduce.

However, there are electric motors per one mains voltage, in which the winding is connected to a star or a triangle inside the electric motor, and only three conductors are connected to the terminal board. Of course, it would be possible, in this case, to disassemble the electric motor, disconnect the phase-to-phase connections, and make three additional outputs. However, this can not be done by using one of the circuits of the motor in a single-phase network, which are given below.

A schematic diagram of the connection of a three-phase electric motor with six leads to a single-phase network is shown in Fig. 3-22, a. To do this, the two phases are connected in series and connected to a single-phase network, and the third phase is connected to them in parallel, including the starting element 1 with switch 2. The starting element can be an active resistance or a capacitor. In this case, the working winding will occupy 2/3 of the stator slots, and the starting 1/3. Thus, the three-phase winding provides the required ratio of the slots between the working and starting windings. With this connection, the angle between the working and starting windings is 90 ° el. (Figure 3-22, b).

When connecting two phases in series, it must be ensured that they are included in accordance with, and not oppositely, when n. from. connected phases are subtracted. As can be seen from the circuit in Fig. 3-22, a, the ends of the second and third phases C 5 and C 6 are connected to a common point.

It is possible to use a three-phase electric motor and as a capacitor according to the circuit in Fig. 3-23 with one operating capacitor 1 or with a working 1 and a starting 2 capacitors. With this switching circuit, the capacity of the working capacitor, μF, is determined by the formula:

where I is the rated current of the motor, A; U is the mains voltage, V.

A three-phase electric motor with three terminals and a stator winding connected to a star is connected to a single-phase network as shown in Fig. 3-24. In this case, the capacitance of the working capacitor is determined by the formula

The capacitor voltage U 1 = 1.3 U.

A three-phase electric motor with three terminals and a stator winding connected in a triangle is connected to a single-phase network as shown in Fig. 3-25. The capacity of the working capacitor is determined by the formula

The capacitor voltage U = 1.15 V.

In all three cases, the capacitance of the start capacitors can be approximately determined from relation

![]()

When selecting the wiring diagram, the voltage to which the three-phase motor is designed and the voltage of the single-phase network should be guided. The phase voltage of the three-phase

Example.A three-phase electric motor with a power of 250 W, voltage 127/220 V with a rated current of 2 / 1.15 A should be included in a single-phase network with a voltage of 220 V.

When using the circuit in Fig. 3-24 capacity of the working capacitor:

![]()

voltage on the capacitor U 1 = 1.3 220 = 286 V.

Starting Capacitor Capacity

When using a three-phase electric motor as single-phase, its power is reduced to 50%, as a single-phase capacitor - up to 70% of the rated power of a three-phase electric motor.

N.V. Vinogradov, Yu.N. Vinogradov

How to calculate and make an electric motor

Moscow 1974